- BEAMIT to support Avio Aero on technology development relating to certain additively manufactured components for the GE9X and Catalyst engines

- GE Additive to become BEAMIT’s strategic equipment supplier moving forward

- BEAMIT to support the development and qualification of GE Additive’s Concept Laser M Line system

- Future intention to develop a dedicated, fully digitalized and sustainable production line

RIVALTA DI TORINO, ITALY – 23 SEPTEMBER 2021 – Avio Aero and GE Additive have signed a non-binding letter of intent (the “LOI”), outlining a strategic technology collaboration agreement with BEAMIT Group (BEAMIT) partly owned by SANDVIK.

Under the LOI, BEAMIT would collaborate with Avio Aero on technology development and, in particular, the post-processing of certain additively manufactured components for the GE9X and the Catalyst engines.

“Industrializing metal additive manufacturing in aerospace continues at pace, and we need trusted partners in our ecosystem who can grow with us. I am thrilled that we are strengthening our relationship with BEAMIT and its shareholder Sandvik. BEAMIT’s sound strategic vision and the wider team’s advanced additive expertise is world-class,” said Riccardo Procacci, CEO of Avio Aero and GE Additive.

“It is an honor for me to enter into this LOI with GE for projects of this magnitude. Being where we are today, as one of the largest, most integrated and advanced additive manufacturing groups in the world, we are in a position to offer leading capabilities across the entire AM value chain, also through our shareholder Sandvik’s leading material expertise and extensive metal powder capabilities. This definitely confirms the hard work that started seven years ago as a vision, and has been pursued with great commitment and strength,” said Mauro Antolotti, President, BEAMIT Group.

BEAMIT is a longstanding GE Additive customer and operates a fleet of Concept Laser and Arcam EBM machines, including the Mlab, M2 and X Line platforms, as well as two Q10plus machines across its subsidiaries – Pres-X and Zare – serving customers in multiple industries, including aerospace, defense and medical.

The intention is for GE Additive and BEAMIT to cooperate on a number of strategic projects, such as special post-processing machinery and technologies as well as materials, to meet long-term production needs.

GE Additive would become BEAMIT’s strategic equipment supplier, as it continues to scale its operations and enhances its existing facilities to meet long-term production needs.

The LOI includes collaboration and assessment on post-processing technologies for the specific requirements of certain GE9X and Catalyst engine components such as MRI and tomographic inspection, HIP and machining equipment. BEAMIT would contribute to the reduction of the lead times necessary to build components, including machining and testing processes, and it would also support new modalities under development at Avio Aero with super-cleaning and super-finishing surfaces.

BEAMIT would also support in the development of GE Additive’s Concept Laser M Line system. The M Line is a highly advanced, industrialized production system that is best suited to experienced metal additive users who have already started to scale production volumes. M Line’s stitching capability enables customers with large part size demand to increase productivity and drive cost out for additive production.

The BEAMIT team would work with GE Additive to fine-tune and qualify the M Line, specifically for aerospace components in accordance with the necessary qualitative requirements. In connection with this activity, BEAMIT would file for and obtain the aerospace qualification for a dedicated R&D division that it would establish.

In the mid-term future, as GE and BEAMIT grow together, BEAMIT has the intention to further expand its operations and develop a completely digitalized and sustainable production line, dedicated to the production of “engine ready” components, for assembly, where the GE parts will be produced. In parallel with this LOI, BEAMIT has recently opened a brand new facility, fully dedicated to coatings, in order to enhance the special process range available for the wider aerospace sector.

The projects contemplated by the LOI go a long way to help BEAMIT achieve its ‘One Stop Shop’ approach, which is driven by market demand, technological evolution and the inclusion of new processes and new accreditations. Today, the entire BEAMIT Group is covered by five NADCAP accreditations – with three new others in progress – and by the TULPS for defense-sector activities. BEAMIT has also started the ISO 14001, ISO 45001 and EASA part 21 pathway.

“Our strategic and industrial partnership with our shareholder Sandvik gives us a competitive advantage when it comes to leading materials expertise, materials development capabilities and supply of the widest range of alloys. Now, making the ‘One Stop Shop’ concept a reality, together with the digital integration of the entire value chain, is a differentiating element, which can play an essential role in making additive manufacturing even more sustainable - without a waiver to the technical advantages offered by technology. In Avio Aero and GE Additive we have found companies that share a similar strategic vision and a strong focus on the research of new materials for additive manufacturing as well as new technologies,” said Andrea Scanavini, Group General Manager, BEAMIT Group.

“Ultimately, the digitalized factory is a key element of our mid-term strategy to enable a win-win relationship with GE. A dedicated factory where all the manufacturing phases are installed and directly interconnected allows us to reach the maximum grade of efficiency, high productivity and total quality required by GE,” he added.

- ends -

Editors' Note

Image above shows Andrea Scanavini, general manager BEAMIT (back right) visiting GE Additive Lichtenfels with Avio Aero’s Dario Mantegazza (front right) and Dario Mula (front left) – September 2021. Image credit: GE Additive/Wilm Visuals

About BEAMIT Group

BEAMIT Group is one of the most advanced additive manufacturing service providers in the world and serves the most demanding industries through its strategic positioning as a one-stop shop: the first company to become a truly global additive manufacturing (AM) hub offering a fully integrated value chain. Based in Fornovo di Taro (Parma, Italy), BEAMIT has been operating in the field of AM with metal powders for 24 years. With close to 60 dedicated AM systems distributed across 7 facilities in Italy and the UK, the Group now counts over 140 employees.

BEAMIT Group specialises in high-end metal AM components for demanding industries like aerospace, automotive, energy, racing and industrial engineering, and holds many relevant quality certifications, including AS/EN 9100:2018 for aerospace, IATF Automotive, NADCAP accreditation for heat treatment processes and laboratories, and NADCAP accreditation for welding – additive manufacturing commodity.

In 2019, Sandvik Group, global leader in hi-tech engineering and metal powder with the widest range of alloys for additive manufacturing as well as remarkable expertise in AM printing technologies for advanced metal components, acquired a significant stake in BEAMIT.

In 2020, BEAMIT acquired a significant stake in PRES-X, an innovative start-up in the field of special post-production processes for 3D printing. BEAMIT then acquired 100% of Italian AM service bureau ZARE.

In 2021, BEAMIT Group acquired 3T Additive Manufacturing (Newbury, UK). 3T Additive Manufacturing holds some of the highest quality certifications for deliveries to aerospace and medical and is an approved supplier for serial production by many leading OEMs across the UK, Europe, US and Japan. BEAMIT Group has a turnover of €22 million.

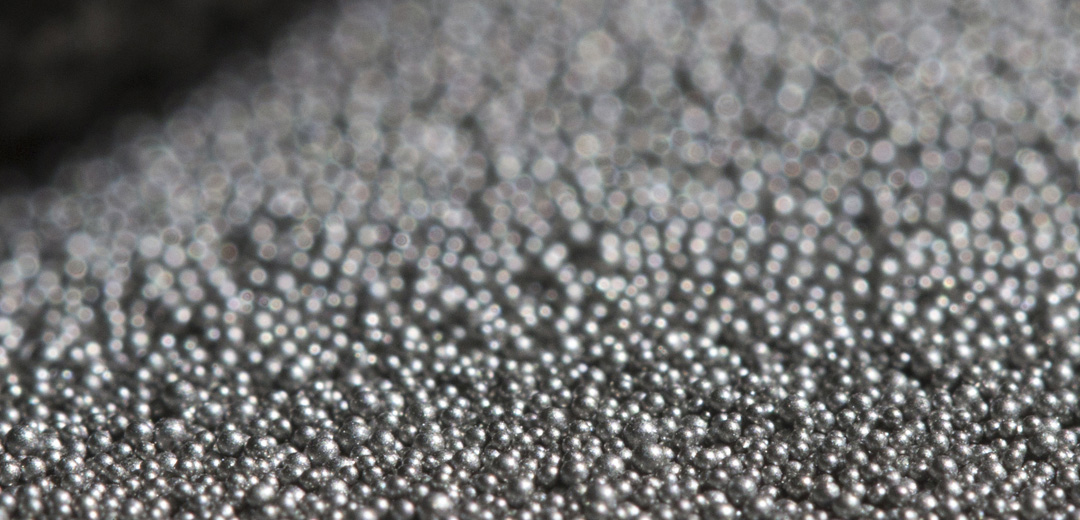

About Sandvik Additive Manufacturing

Sandvik Additive Manufacturing has a world-leading position in metal powder with the widest range of AM-alloys on the market. The company has also made sizeable investments into a wide range of AM printing technologies since 2013. Adding 159 years of leading expertise in materials technology, 75 years in post processing methods like metal cutting, sintering and heat treatment, Sandvik has well established and leading competence across the entire additive value chain. In 2019, Sandvik acquired a significant stake in the BEAMIT Group, a leading European-based AM service provider, and in 2020 and 2021, the BEAMIT Group acquired 100% of ZARE in Italy and 3T Additive Manufacturing in the UK, bringing together three leading AM service bureaus in Europe – to create one of the largest independent AM service providers in the world, serving the most demanding industries. Sandvik AB is a high-tech and global engineering group with approximately 37,000 employees and sales of approximately 86 billion SEK in more than 160 countries (2020). The company was founded in Sweden in 1862.

About Avio Aero

Avio Aero is a GE Aviation business that designs, manufactures and maintains propulsion systems for civil and military aviation. It is the center of excellence for the entire General Electric group in the field of mechanical transmissions and low-pressure turbines. The company’s headquarter and largest production plant are in Rivalta di Torino, its other Italian main plants are located in Brindisi and Pomigliano d’Arco (Naples), where it employs more than 4,300 people. Abroad, it has a plant and a test center in Poland and a plant in Czech Republic, in which works 900 employees. Founded in 1908, the company has overcome many technological challenges in over a century of history. Continuous investments in research and development and an established network of relationships with leading universities and international research centers have enabled Avio Aero to develop technological and manufacturing excellence recognized across the globe: an achievement borne out by a range of collaborative partnerships with key operators in the global aviation industry.

About GE Additive

GE Additive – part of GE (NYSE: GE) is a world leader in metal additive design and manufacturing, a pioneering process that has the power and potential to transform businesses. Through our integrated offering of additive experts, advanced machines, and quality powders, we empower our customers to build innovative new products. Products that solve manufacturing challenges, improve business outcomes, and help change the world for the better. GE Additive includes additive machine brands Concept Laser and Arcam EBM, along with additive powder supplier AP&C.