Webinar: Die M Line von GE Additive löst Stitching-Probleme für die Multilaserproduktion

Infolge der Erhöhung der Zahl der Energiequellen zur Produktivitätssteigerung ergeben sich eine Vielzahl von Herausforderungen. Diese betreffen die tatsächliche Leistung, Genauigkeit und auch die Langzeitstabilität von Multilasermaschinen. Nehmen Sie an diesem Webinar teil, um mehr über die M Line zu erfahren und wie sie neue Maßstäbe für die additive Fertigung von Metallen setzt.

Die Innovation in der additiven Fertigung von Metallen schreitet rasant voran. Da sich die Verbesserungen in fast allen Prozessschritten und kritischen Teilsystemen innerhalb der gesamten additiven Prozesskette fortsetzen, ist die Verbesserung der Produktivität heute sicherlich eines der wichtigsten Themen. Die Verbesserung der Produktivität ist ein grundlegender und notwendiger Schritt, um Business Cases für die additive Fertigung zu schaffen und dient als ein zentrales Argument für die Verdrängung herkömmlicher Herstellungstechniken. Infolge der Erhöhung der Zahl der Energiequellen zur Produktivitätssteigerung ergeben sich eine Vielzahl von Herausforderungen. Diese betreffen die tatsächliche Leistung, Genauigkeit und auch die Langzeitstabilität von Multilasermaschinen.

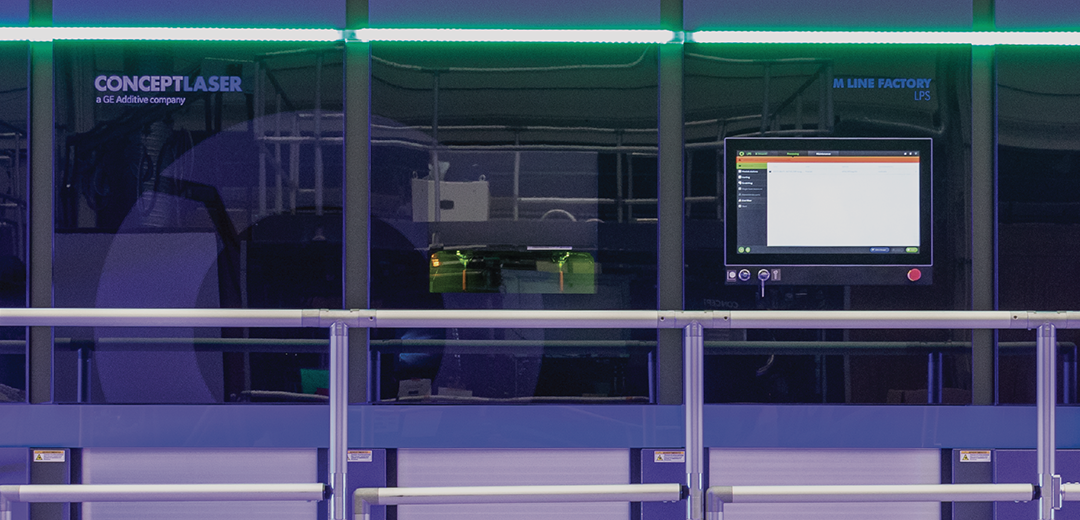

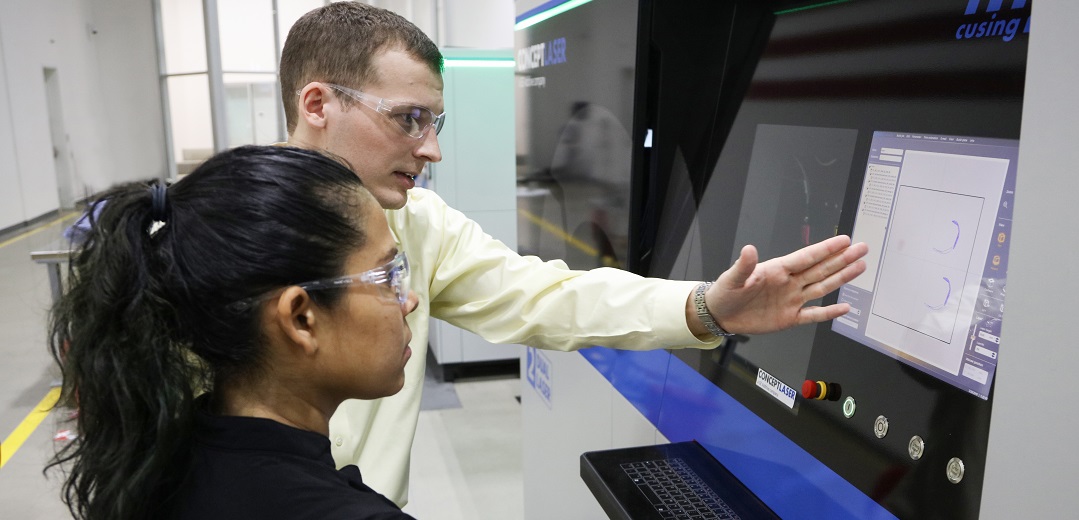

Da sich die additive Fertigung von Metallen von der Herstellung von Kleinserien oder Einzelteilfertigung immer weiter entwickelt, erkennen nun zahlreiche Hersteller das Wachstum und das Potenzial der additiven Fertigung in der Serienproduktion. Die Concept Laser M Line von GE Additive ist mehr als eine einzelne Maschine. Es handelt sich um ein System, das speziell für die additive Fertigung von Metallen und im Hinblick auf Sicherheit, Zuverlässigkeit, Wiederholbarkeit und Effizienz entwickelt wurde. Anstatt bestehende Maschinen nachzurüsten, hat GE Additive die M Line von Grund auf neu entwickelt und dabei einen ganzheitlichen Ansatz zum Verständnis, zur Messung und kontinuierlichen Verbesserung dieses Multilaser-Produktionssystems integriert.

Nehmen Sie an diesem Webinar teil, um mehr über die M Line zu erfahren und wie sie neue Maßstäbe für die additive Fertigung von Metallen setzt.

Sprecher:

Benedikt Roidl ist Senior Engineer bei GE Additive mit mehr als fünf Jahren Erfahrung im Bereich additive Fertigung. Während seiner Karriere bei GE Additive hatte er verschiedene Positionen im Ingenieurwesen inne. Davor arbeitete er an der RWTH Aachen, bei Eovent und an der Universität von Tokyo. Benedikt hat in numerischer Simulation und Aerodynamik promoviert und verfügt über mehr als 15 Jahre Erfahrung im Ingenieurwesen.