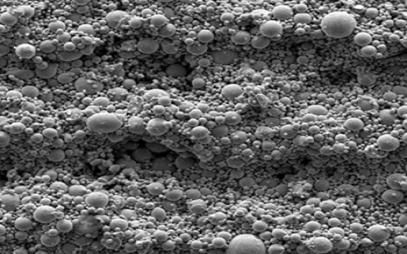

Metal powder is a very important element of the metal additive manufacturing (AM). Critical factors influencing powder attributes must be managed carefully through its entire life cycle to produce quality parts at a competitive cost. The life cycle of metal powder includes powder production, shipment, and various additive part manufacturing steps. Powder quality and consistency needs to be maintained at each step of the process, including powder storage and handling. This requires risk assessment and an abatement plan, along with detailed work instructions/specifications and inspection details. Important elements of metal powder include development of required physio-chemical properties, wide supply base, consistent/cleaner powder, and competitive cost.

This webinar will discuss powder related critical factors, life cycle steps, specification strategy and technical studies and process for development, which can potentially lead to a wider adoption of additive technology.

Speaker

Rajendra M Kelkar

Principal Engineer

GE Additive

Rajendra M Kelkar (Raj) is a principal engineer with GE Additive in Cincinnati, OH. He is passionate about powder metallurgy and has worked on press and sinter, metal injection molding (MIM), laser additive manufacturing (DMLM) and is now with binder jet (BJ) technologies. He has worked across multiple business sectors like automotive, oil & gas and Aviation, covering a wide variety of material systems including iron-, cobalt-, nickel-, and titanium-based alloys as well as hard materials such as WC-Co.

Raj joined GE Aviation in 2011 and became a focal on MIM efforts for aircraft engine parts. He has worked on AM with GE Aviation since 2012. He led material and process efforts on the fuel nozzle for GE’s LEAP engine manufactured via DMLM using CoCr alloy and TRL development on alloy718 for Catalyst engine program. Raj successfully completed powder vendor qualifications, and powder reuse studies for those programs. He has authored key internal specifications. Currently his focus is on materials, process, and application development for automotive customers using binder jet technology. Raj has nine technical publications/conference presentations and eight patent filings to his credit.

Before joining GE, he has worked with SSI Technologies and Kennametal in developing and providing materials solutions to customers. He worked with ISPL India on heat treatment of steels and with Birla copper, on copper smelting.