Join this free webinar to hear how GE Aviation's early experience creating an additive production part has evolved into the industrialization of parts and systems using additive manufacturing across multiple engines. It will also address how enhancements to GE Additive’s M2 Series 5 machine has made it an ideal machine for aerospace production.

GE Aviation garnered international recognition for the development of the LEAP fuel nozzle, the first jet engine part designed specifically for metal additive. Hundreds of thousands of the fuel nozzles have been produced since its introduction, ushering in the era of metal additive production.

But, what has been happening since the fuel nozzle was developed? Where has GE Aviation taken metal additive beyond the production of that single part and what have they learned from their experiences?

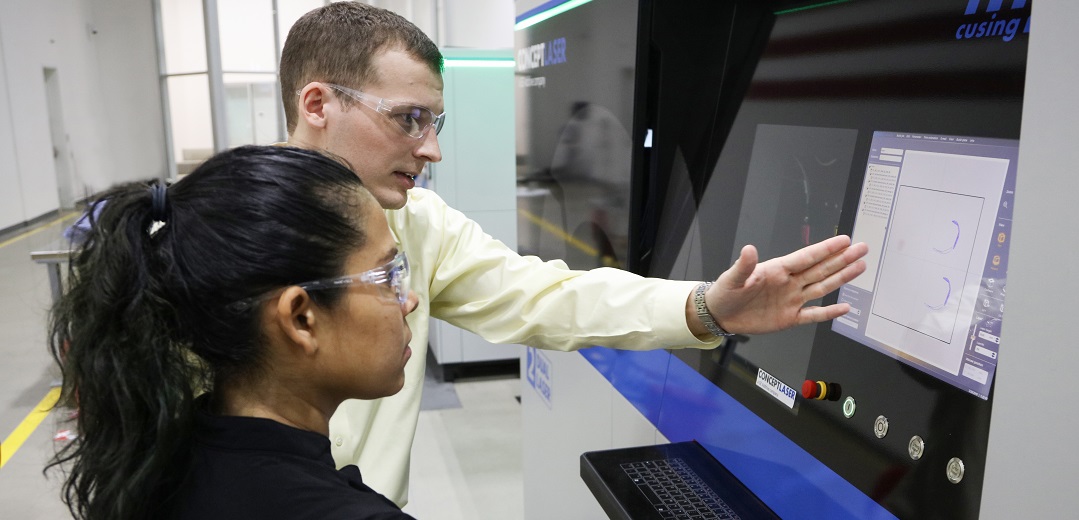

Join GE Aviation’s Benito Trevino and Chris Philp for this free webinar as they reveal how the early experience creating an additive production part has evolved into the industrialization of parts and systems using additive manufacturing across multiple engines. They will also discuss how enhancements to GE Additive’s M2 Series 5 machine have made it an ideal machine for aerospace production.

Presenters

Benito Trevino

General Manager for GE Aviation’s Additive Integrated Product Team

GE Aviation

Benito Trevino serves as the general manager for GE Aviation’s Additive Integrated Product Team (IPT) and has overall leadership responsibility for the additive product development site (ATC), the additive side of the Auburn production facility, global launch responsibility for additive hardware inclusive of Avio and strategic alignment to all global engineering additive labs (BEC, EDC, GEIQ, TTC and the Turin Additive Lab).

Benito began his career with GE in 1999 on the Edison Program with GE Lighting. He had multiple roles at GE Lighting before transitioning to the Aeroderivatives business within GE Power in 2005. He held roles of increasing responsibility at Power, including serving as packaging systems leader for the LM2500 product line.

In 2012 Benito transitioned to GE Aviation as a product definition engineering sub section manager in Lynn, Massachusetts, and was subsequently promoted to evaluation engineering section leader in 2014. He moved to Victorville, California, in 2015 to serve as the flight test operation site leader and was promoted to lead test systems engineering in 2016 which brought him back to Evendale.

In 2019, Benito was selected to serve as lean deployment champion for Engineering. During his tenure, he launched the Engineering Kaizen Promotion Office and partnered with other engineering leaders and lean deployment champions to drive continuous improvement in the areas of employee safety, inclusion & diversity, engine rotor hardware robustness, hot section durability, customer responsiveness, product cost & producibility and technology maturation. He also drove effective execution and rigorous governance in the areas of compliance, operations, lean deployment and employee safety.

Most recently, Benito served as customer technology programs director for the GE90 and GP7200 product lines where he partnered cross functionally to improve time on wing (TOW) performance through continuous improvement activities in the areas of on/near wing technology, shop visit workscoping, cost and TAT, material demand forecasting and CSA productivity.

Chris Philp

Additive Technology Center Site Leader

GE Aviation

Chris Philp is the site leader of GE Aviation’s Additive Technology Center (ATC) in the US.

Originally from the UK, he holds a Master’s Degree in Mechanical Engineering from the University of Sheffield and has extensive experience in both non-conventional machining and additive manufacturing. Having previously worked in various divisions of both GKN Aerospace & GE Aviation, Chris currently leads a 150-person site, dedicated to the development and industrialization of commercial and military additive components for GE Aviation.

Chris has been the main proponent for introducing Concept Laser machines into GE Aviation’s additive machine portfolio over the past five years. He has an in-depth understanding of and appreciation for what it takes to industrialize additive manufacturing processes for the aviation industry.

Beyond the Fuel Nozzle: How GE Aviation is Using Metal Additive for Production Parts