Webinar: Point Melt: An Evolution in Electron Beam Melting Technology

With Point Melt, a new journey begins in what can be achieved with EBM concerning building without any supports; surface finish and microstructural control.

Electron Beam Melting is a cost-efficient and proven additive manufacturing solution that has developed rapidly over the last years as a result of dedicated system development. Significant improvements have been made concerning system productivity, system reliability and part quality of built parts, turning EBM into a mature production technology. Today, EBM is an integral part of several production chains in various applications.

EBM is used for production of CE-certified and FDA-cleared orthopedic implants. EBM is also used for production of aero engine components by several OEMs and Tier 1 suppliers in the aerospace industry, with the common goal to use the EBM technology for series production of commercial aero engine components.

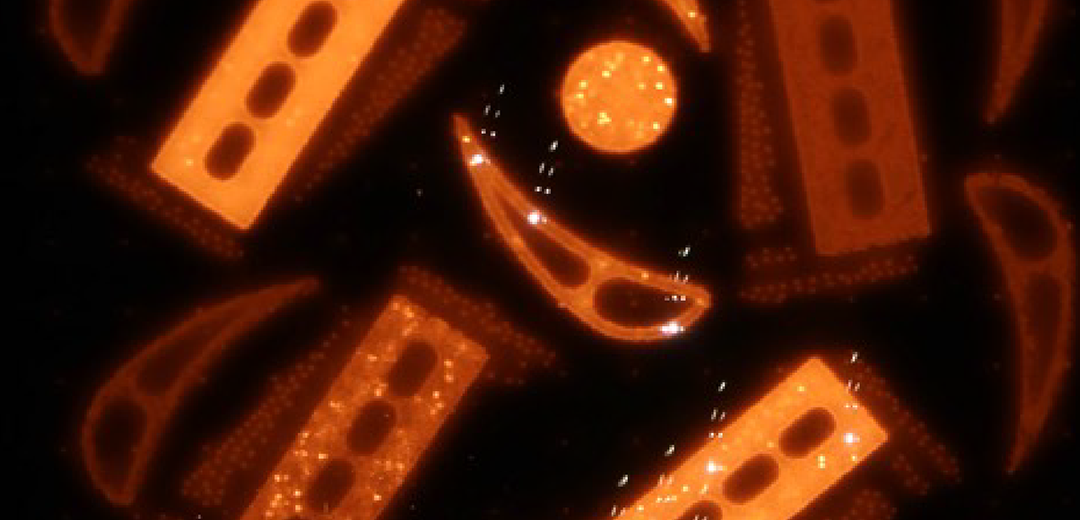

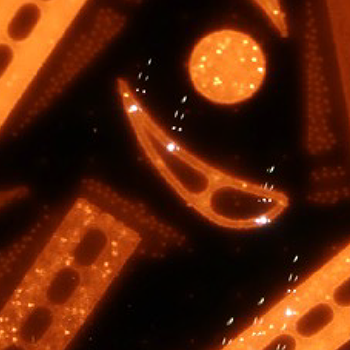

Recent innovations in beam control have led to a revolutionary new melting strategy using point exposures instead of traditional hatched line melt. With Point Melt, a new journey begins in what can be achieved with EBM concerning building without any supports; surface finish and microstructural control.

Join this webinar as GE Additive’s Mattias Fager describes how Point Melt was developed and explores the many benefits that result from this innovation.

Speaker

Mattias Fager

Senior Staff Engineer, Materials Science and Engineering, GE Additive

With a background in solid state physics, Mattias Fager joined the metal additive industry in its genesis in 2001. Mattias has experience in research and development as well as sales and application development, as both as manager and tech lead. He has been an integral part in both introducing AM to the medical industry as well as guiding the GE9X LPT EBM production through the engine test programs. Mattias is one of the true process architects behind the success of EBM.