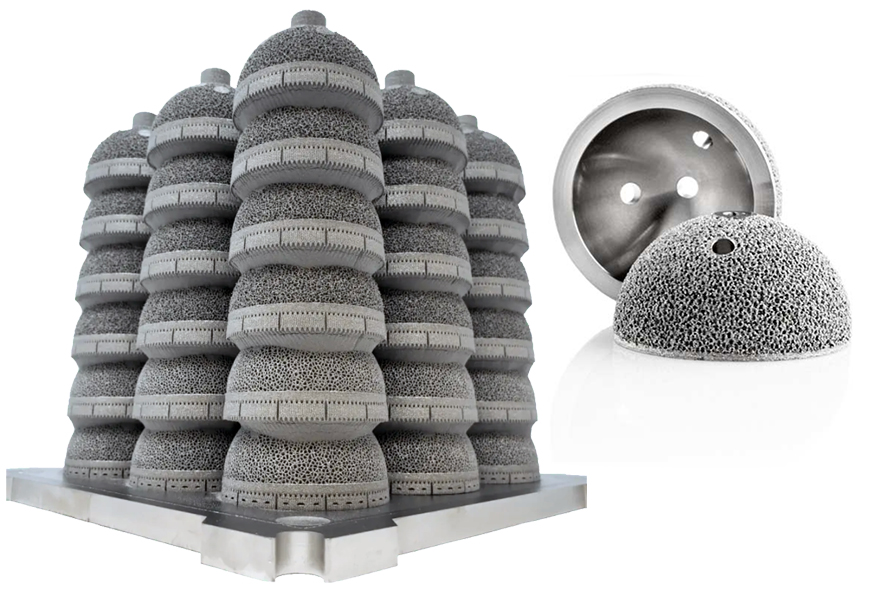

Additive Manufacturing for Orthopedic Implants

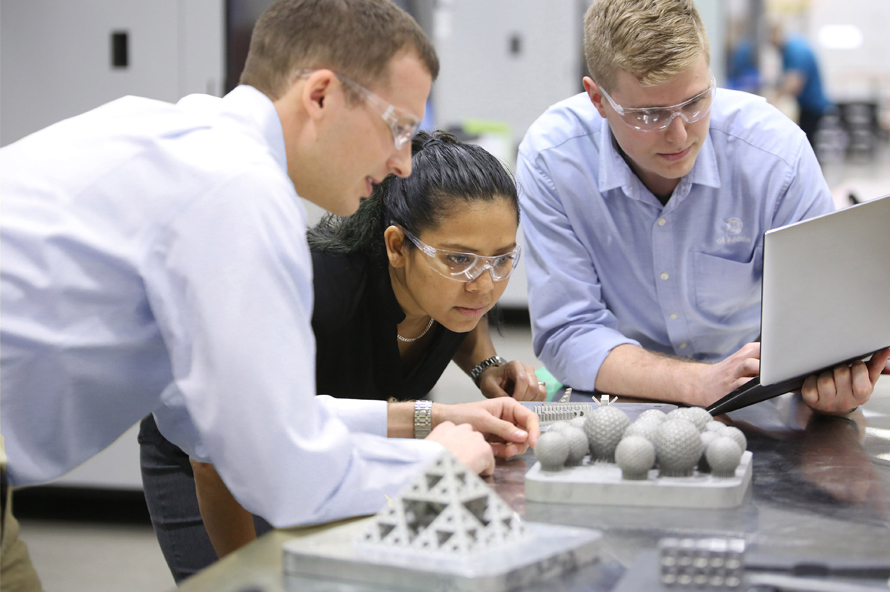

Revolutionize medical implants and remove barriers to customizations. For the ready, we have a way to get there faster. To drive productivity and customization and improve safety and patient care. When you’re ready to deliver cost-efficient, patient-specific orthopedic implants using AM, the pioneers of full metal additive production are ready to help.

Customer stories

Help improve orthopedic applications and drive cost savings

with proven metal additive solutions.

Tomas Kellner

19 September 2019