Access Open Orders

Before you begin

Procedure

- Log in to Plant Applications Web Client.

- Select

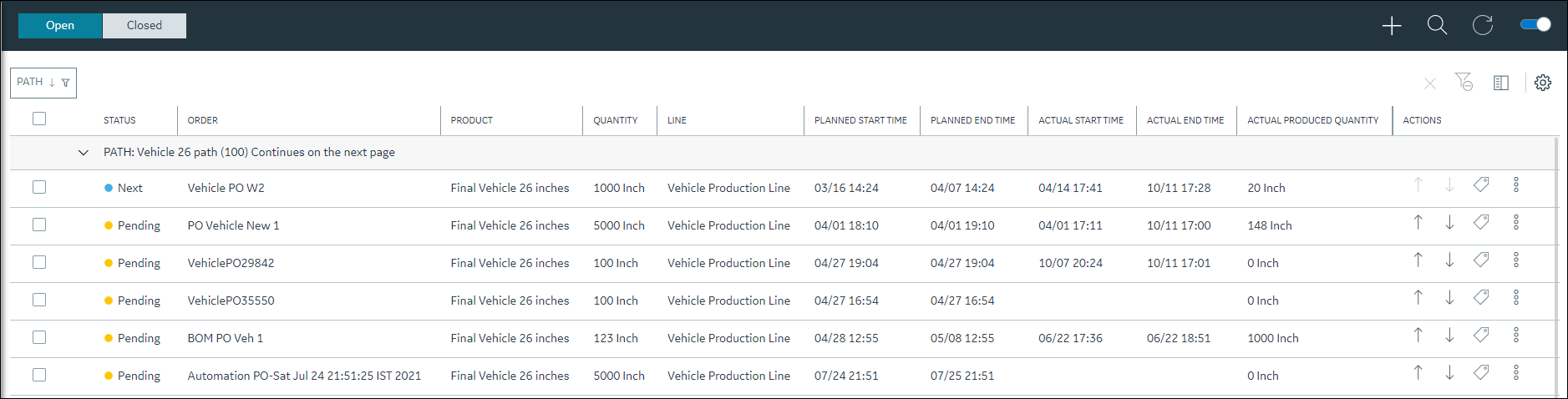

. By default, the Open page appears, displaying a list of process orders grouped based on the multiple execution paths (configured in Plant Applications Administrator) or unbound path in a tabular format.Note: The unbound Process Orders are always displayed on Plant Applications Web Client in the Unbound category. The path column is not displayed separately, because the process orders are grouped by the path column. User can use the PATH filter to filter out the Unbound POs from being displayed. The filter selection will persist for the user.The process orders are sorted based on their status. By default, the sorting order is Active, Next, Pending, or Planning. However, you can change this sorting order using the statusorder and statusgroup parameters in the process-order-status-controller api end point.In the table displaying the list of open orders and their details, you can resize a column or drag and drop a column to a new position. The column settings you select in the table are retained when you access the Open page later. You can select the path headers to either collapse or expand the list of process orders associated to that execution path.Note: If you have a process order with custom status, you must define the statusgroup parameter in the process-order-status-controller api end point for it to display in the Open or Closed tabs. By default, the status sorting order is not set and appears at the end on the list. As an administrator, you can change the sorting order using the statusorder parameter in the process-order-status-controller api end point.

. By default, the Open page appears, displaying a list of process orders grouped based on the multiple execution paths (configured in Plant Applications Administrator) or unbound path in a tabular format.Note: The unbound Process Orders are always displayed on Plant Applications Web Client in the Unbound category. The path column is not displayed separately, because the process orders are grouped by the path column. User can use the PATH filter to filter out the Unbound POs from being displayed. The filter selection will persist for the user.The process orders are sorted based on their status. By default, the sorting order is Active, Next, Pending, or Planning. However, you can change this sorting order using the statusorder and statusgroup parameters in the process-order-status-controller api end point.In the table displaying the list of open orders and their details, you can resize a column or drag and drop a column to a new position. The column settings you select in the table are retained when you access the Open page later. You can select the path headers to either collapse or expand the list of process orders associated to that execution path.Note: If you have a process order with custom status, you must define the statusgroup parameter in the process-order-status-controller api end point for it to display in the Open or Closed tabs. By default, the status sorting order is not set and appears at the end on the list. As an administrator, you can change the sorting order using the statusorder parameter in the process-order-status-controller api end point. Note: The number of records displayed in the Open page depends on the value that is configured for the maxRecordsToFetch property in the app.properties.json file.Depending on your installtion, access the app.properties.json file in the following folder:If the number of records in the database is more than the value configured for the maxRecordsToFetch property, a notification to contact the administrator appears.

Note: The number of records displayed in the Open page depends on the value that is configured for the maxRecordsToFetch property in the app.properties.json file.Depending on your installtion, access the app.properties.json file in the following folder:If the number of records in the database is more than the value configured for the maxRecordsToFetch property, a notification to contact the administrator appears.- Enterprise installation: <Install Directory>/PlantApplicationsDocker/plantapps-web-docker/mnt/configfiles/production-scheduler-app/prod/{{appVersion}}/<appname>.yml

- Standard installation: <Install Directory>\config-rep\production-scheduler-app\prod\{{appVersion}}\<appname>.yml

In addition, the following information appears in a tabular format for each process order.Option Action STATUS The process order status along with the corresponding color. - Green: Active

- Blue: Next

- Yellow: Pending

- Orange: Planning

ORDER The unique process order number. LINE The production line description. PRODUCT The product associated with the process order. QUANTITY The planned quantity for the process order. PLANNED START TIME The date and time when the process order was planned to begin. The date and time format is driven by localization setting. For example: mm/dd hh:mm or dd/mm hh:mm. PLANNED END TIME The date and time when the process order was planned to end. The date and time format is driven by localization setting. For example: mm/dd hh:mm or dd/mm hh:mm ACTUAL START TIME The actual start date and time of the process order. The date and time format is driven by localization setting. For example: mm/dd hh:mm or dd/mm hh:mm ACTUAL END TIME The actual end date and time of the process order. The date and time format is driven by localization setting. For example: mm/dd hh:mm or dd/mm hh:mm. ACTIONS The actions that you can perform on a process order. You can select one of the following action items:  and

and  :

Select to change the sequence of a pending process

order.

:

Select to change the sequence of a pending process

order. :

Select to change the status of process order.

:

Select to change the status of process order. :

Select to edit, comment, delete, or advance a

process order.Note: Advance PO Unit is enabled only when the Schedule Control Type path configuration is set to Schedule Flows Independently in Plant Applications Administrator. For more information on advancing a process order, refer to Advance a Process Order.

:

Select to edit, comment, delete, or advance a

process order.Note: Advance PO Unit is enabled only when the Schedule Control Type path configuration is set to Schedule Flows Independently in Plant Applications Administrator. For more information on advancing a process order, refer to Advance a Process Order.

ACTUAL PRODUCED QUANTITY The actual produced quantity for the open process order. - Optional: In the table displaying the list of process orders and their details, select an option to perform an action as described in the following table.

Option Description

Select to Add a New Process Order.

Select to update the process orders list with the latest information. Note:This icon is enabled only when there are updates to the process orders list. Else, one of the following icons appears: : Indicates that there are no updates to the process orders list.

: Indicates that there are no updates to the process orders list. : Indicates that there are additional open process orders available. Select

: Indicates that there are additional open process orders available. Select  to refresh the page and access all the open process orders.

to refresh the page and access all the open process orders.-

: Indicates that the RabbitMQ service is down.

: Indicates that the RabbitMQ service is down.

Select to automatically update the process orders. You can disable this if you do not want to update the newly added process orders. PATH

Select to filter the process orders based on the selected path. Select a check box, and then select Apply to include the process orders that are grouped by selected paths in the results.

Select to delete multiple process orders. Note: This icon is enabled only when you select the check boxes for one or more process orders in the table.

Select to add or remove columns from the table displaying the process orders list. The added columns are retrieved when you access the Open page later. By default, the following columns appear in the specified order when you access the Open page:- STATUS

- ORDER

- PRODUCT

- QUANTITY

- LINE

- PLANNED START TIME

- PLANNED END TIME

- ACTUAL START TIME

- ACTUAL END TIME

- ACTUAL PRODUCED QUANTIY

- ACTIONS

Tip: You can use the horizontal scroll bar in the table to drag the scroll box and access the data from all the added columns.