5.4. SPC Variable: Limits

In order to set control limits for your chart sets, SPC provides you with several different options. If you know the limits that you want to set, you can use Points or Values. If the process is new and you would like to have limits calculated automatically for you, you can use the auto recalculation features. Whatever your preference, SPC provides you with an option.

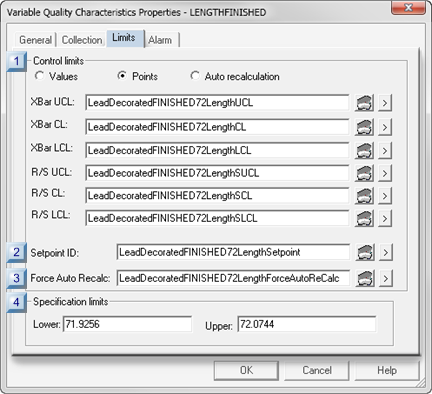

| 1 | Control Limits |

| 2 | Setpoint ID |

| 3 | Force Auto Recalc |

| 4 | Specification limits |

| 5 | Control Limits: Guidelines |

| 1 | Control Limits |

The control limits source types are as follows.

- Values

- Points

- Auto recalculation

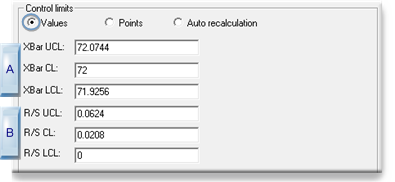

Values

You can use your own absolute criteria to set control limits. Generally, when absolute values are used, the process is assessed to be in control.

Check Values.

Entries include the following.

| A | XBar UCL; XBar CL; XBar LCL |

| B | R/S UCL; R/S CL; R/S LCL |

| A | XBar UCL; XBar CL; XBar LCL |

Provides absolute values for the samples' limits.

| XBar UCL | XBar Upper Control Limit |

| XBar CL | XBar Center Line |

| XBar LCL | XBar Lower Control Limit |

| B | R/S UCL; R/S CL; R/S LCL |

Provides absolute values for either the samples' range or sigma limits.

| R/S UCL | Range or Sigma Upper Control Limit |

| R/S CL | Range or Sigma Center Line |

| R/S LCL | Range or Sigma Lower Control Limit |

The limits type depend on whether XBar-R or XBar-S was selected as the calculation type on the General tab in the Variable Quality Characteristics dialog box.

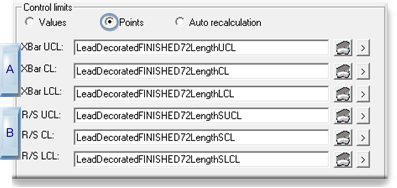

Points

Points can provide the control limit values that can be easily changed, when necessary simply by changing their value (e.g. in the Point Control Panel). The new value will display on the chart when the chart updates.

| A | XBar UCL; Bar CL; XBar LCL |

| B | R/S UCL; R/S CL; R/S LCL |

| A | XBar UCL; XBar CL; XBar LCL |

Provides point ID's whose value identifies the samples' limits.

| XBar UCL | XBar Upper Control Limit |

| XBar CL | XBar Center Line |

| XBar LCL | XBar Lower Control Limit |

| Point Type | Analog |

| B | R/S UCL; R/S CL; R/S LCL |

Provides point ID whose values either the samples' range or sigma limits.

| R/S UCL | Range or Sigma Upper Control Limit |

| R/S CL | Range or Sigma Center Line |

| R/S LCL | Range or Sigma Lower Control Limit |

| Point Type | Analog |

The limits type depend on whether XBar-R or XBar-S was selected as the calculation type on the General tab in the Variable Quality Characteristics dialog box.

- If you use Points for general characteristics on limits rather than specific values, SPC will alert the user when the values become specific at runtime. If SPC detects configuration inconsistencies, it will display an $SPC_ADMIN_ALARM in the Alarm Viewer.

- Points need to be logged to be validated.

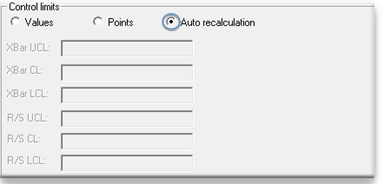

Auto recalculation

One of the many advantages SPC offers is its ability to automatically calculate the control limits for a process. This is particularly useful if your process is new and you want SPC to generate control limits.

Check Auto recalculation.

SPC recalculates the relevant control limits when the selected chart updates.

- When your process is new or in optimum condition, calculate the limits using the Auto Recalculation or Force Auto Recalculation option.

- Once you determine that SPC has automatically collected enough data to calculate the correct control limits, disable the automatic calculation option.

- The calculated control limits are then used for the life of the process.

- Control limits produced by auto recalculation are valid only when your process is "in control." If you calculate them while your process is going "out of control," then the limits will be incorrect.

- A global variable SPC_RESIZE_OUT_OF_BOUNDScauses graph re-scaling and re-centering.

SPC_RESIZE_OUT_OF_BOUNDS is enabled by default.

When the SPC_RESIZE_OUT_OF_BOUNDS is disabled charts are not re-scaled and re-centered.

| 2 | Setpoint ID |

A setpoint entered in the Setpoint ID field enables usage of the current XBar, Range or Sigma control limits values elsewhere in the selected project or downloaded to a device.

The array contains values for the following.

- XBar LCL

- XBar CL

- XBar UCL

- R/S LCL

- R/S CL

- R/S UCL

| Point type | Floating (Real) array point of 6 elements |

| 3 | Force Auto Recalc |

A point can be used to Force Auto Recalc in addition to specifying control limit values or points. This option provides the flexibility to reset control limits during runtime.

As a result, when you send an application to production, you can have SPC recalculate the control limits so that they are accurate for the process.

| Point On/Off | Set to: | Auto-calculation is: |

|---|---|---|

| Point On | TRUE | Activated and the XBar-R/S control limits are recalculated. Pre-set values are ignored. |

| Point Off | FALSE | Deactivated and the last calculated values are used. Pre-set values are ignored until the data collector is restarted or dynamically refreshed. |

| Point type | BOOLEAN | |

- Whenever the Force Auto Recalc point is set to either TRUE or FALSE, the data collector will drop the current sample and start over .

- When the control limits have been automatically recalculated and the process is assessed to be under control, disable the Force Auto Recalc option.

| 4 | Specification limits |

Entered values for specification limits are the maximum and minimum tolerances set to determine acceptable limits for the variable.

The values may or may not be the same as the upper and lower control limits.

| Lower | Lower specification limit. |

| Upper | Upper specification limit. |

| Point Type | Analog |

| 5 | Control Limits: Guidelines |

- When your process is new or in optimum condition, calculate the limits using the Auto Recalculation or Force Auto Recalculation option.

- Once you determine that SPC has automatically collected enough data to calculate the correct control limits, disable the automatic calculation option.

- The calculated control limits are then used for the life of the process.

- Control limits produced by auto recalculation are valid only when your process is "in control." If you calculate them while your process is going "out of control," then the limits will be incorrect.

- A global variable SPC_RESIZE_OUT_OF_BOUNDScauses graph re-scaling and re-centering.

SPC_RESIZE_OUT_OF_BOUNDS is enabled by default.

When the SPC_RESIZE_OUT_OF_BOUNDS is disabled charts are not re-scaled and re-centered.