Proficy Plant Applications

Improve efficiency, production management and quality with a proven, modular MES for process, discrete and mixed manufacturing

Automotive industry

Leveraging new software capabilities to efficiently scale EV battery manufacturing

How will battery manufacturers meet the five-fold increase in electric vehicle (EV) battery production needed by 2030?

Decarbonization of the transportation sector cannot be achieved without this massive build-out of EV battery production capacity. Governments worldwide are encouraging domestic production to attract jobs and promote long-term economic security, while simultaneously striving to mitigate long-term geopolitical and supply chain risks. Over the next seven years, manufacturers will be competing to increase their production capacity while simultaneously reducing their production costs.

Top Challenges for EV battery manufacturers include:

This white paper explores each of these challenges in detail and illustrates how GE Digital’s Proficy software helps manufacturers tackle them. In particular, learn the critical role Proficy Smart Factory analyst-recognized Manufacturing Execution System (MES) plays in providing end-to-end visibility across the diverse battery production environment (i.e. supporting both continuous process and discrete manufacturing activities in a single platform).

Is your battery manufacturing process inefficient with limited capabilities to scale? Are you struggling to meet the traceability requirements for all battery manufacturing?

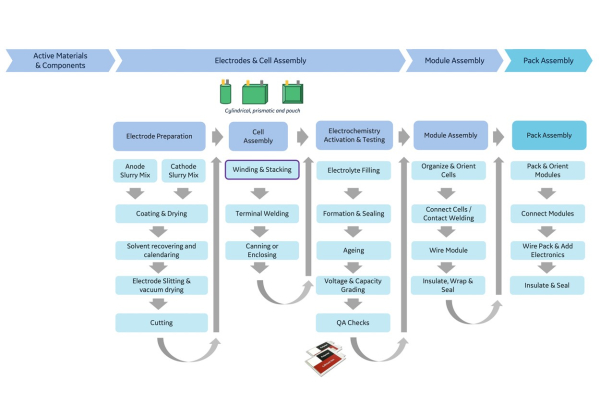

Without question, the battery manufacturing process is complicated. But did you know that you can get end-to-end production data and visibility for each battery pack with a single MES solution?

GE Digital can support your diverse battery production process in one manufacturing platform, decreasing your OT costs and maintenance, and giving you a foundation for operations optimization.

Gartner named GE Digital a Leader in the 2023 Magic Quadrant for Manufacturing Execution Systems for its Proficy Smart Factory (MES) software solution. The evaluation was based on specific criteria that analyzed the company’s overall completeness of vision and ability to execute.

Also, find out why Gartner recognized GE Digital as a Customers’ Choice in the 2023 Gartner® Peer Insights™ Voice of Customer: Manufacturing Execution Systems.

Read your complimentary reports today.

Building a world that works for tomorrow requires all industries to commit to the energy transition and operations resource efficiency. GE Digital works with customers to deliver software solutions that enable a more sustainable tomorrow.

Learn how GE Digital can help you:

Improve efficiency, production management and quality with a proven, modular MES for process, discrete and mixed manufacturing

The automotive industry faces intense transformation. Are your manufacturing operations equipped for success?

Maximize efficiency, flexibility and output with orchestrated, up-to-date manufacturing product data management