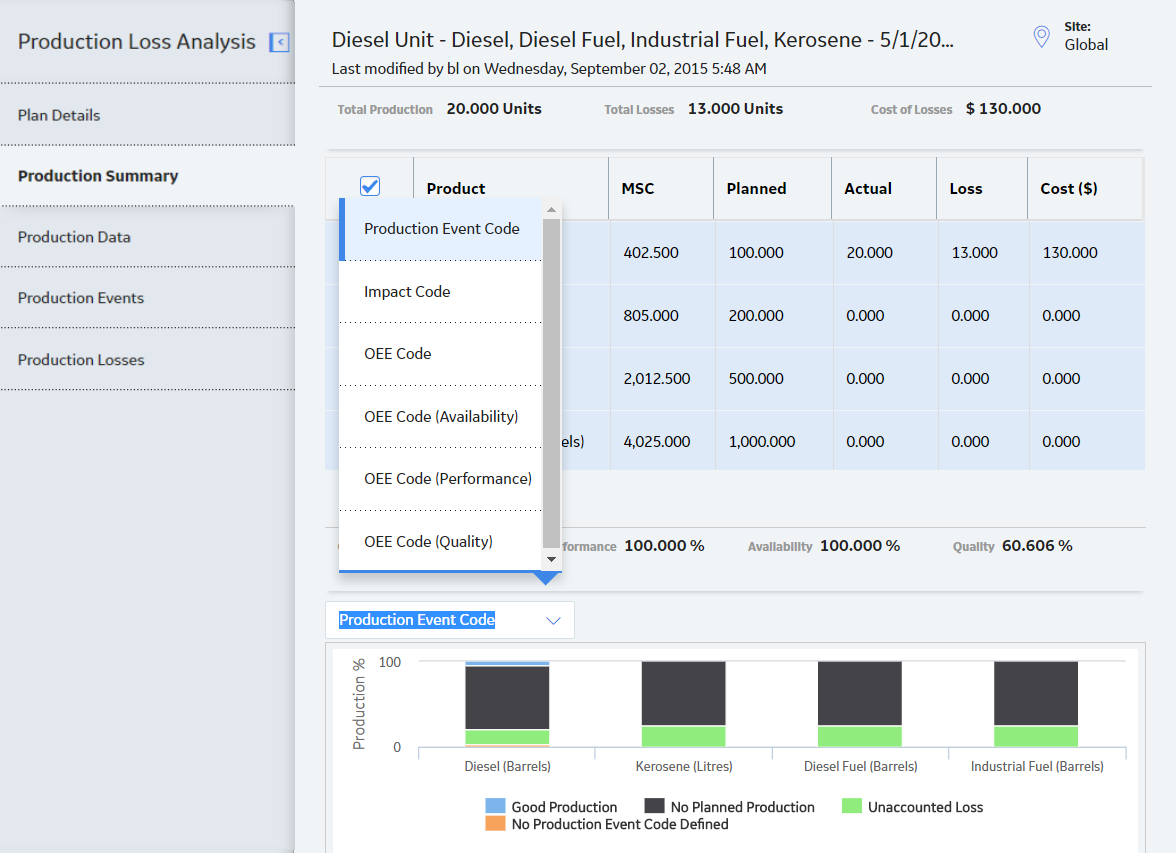

Production Summary Plot

The Production Summary plot displays a graphical representation of the data that exists in the Production Data workspace. The graph is built dynamically and is not stored in the GE Digital APM Catalog.

By default, the plot is configured as a columnar graph.

You can see different Production Data details on the plot using the following categories from the list:

- Production Event Code: Displays information about the production events that are selected in the Production Data workspace.

- Impact Code: Displays information about the impact codes that are selected in the Production Data workspace.

- OEE Code: Displays information about all OEE codes that are selected in the Production Data workspace.

- OEE Code (Availability): Displays information about the availability OEE codes that are selected in the Production Data workspace.

- OEE Code (Performance): Displays information about the performance OEE codes that are selected in the Production Data workspace.

-

OEE Code (Quality): Displays information about the quality OEE codes that are selected in the Production Data workspace.

Production Data Details

The following table provides details about the categories (options in list) and subcategories (legend below the plot) that appear on the Production Summary plots. The calculations used in each subcategory are listed in the Calculation column.

| Subcategory | Main Category | Question | Calculation |

Example |

|---|---|---|---|---|

| Good Production |

Production Event Code Impact Code OEE Code | What percentage of periods contains an Actual value that is greater than or equal to the Planned Production value? |

Good Production = (Σ All Actual Values / Σ All MSC Values) x 100 |

The sum of all Actual values is 45,000. The sum of all MSC values is 65,000. Therefore:

|

| Unaccounted Loss |

Production Event Code Impact Code OEE Code | What percentage of available time was the production unit not scheduled for production? | Unaccounted Loss = [(Σ All Short Range Values - Σ All Actual Values - Σ All Losses) / Σ All MSC Values] x 100 |

The sum of all MSC values is 80,000. The sum of all Short Range Plan values is 65,000. The sum of all Actual values is 45,000. The sum of all Loss values is 16,000. Therefore:

|

| No Planned Production |

Production Event Code Impact Code OEE Code | In what percentage of periods did I reduce the Short Range Value? |

No Planned Production = [(Σ All MSC Values - Σ All Short Range Values) / Σ All MSC Values] x 100 |

The sum of all MSC values is 150,000. One day, the MSC value is 5,000, and the Short Range Plan value is 4,000. So, the No Planned Production Value is 1,000 (5,000 - 4,000). Another day, the MSC value is 5,000, and the Short Range Plan value is 3,000. So, the No Planned Production Value is 2,000 (5,000 - 3,000). Therefore:

|

|

No Production Event Defined |

Production Event Code | What percentage of losses are missing a Production Event? |

NPED = (Σ Losses where the Production Event value is null / Σ All MSC Values) x 100 |

The sum of losses in all Production Loss records where the Production Event value is null is 31,220. NPED = 31,220 |

| No Production Event Code Defined |

Production Event Code | What percentage of losses contain a value in the Production Event field but the corresponding Production Event does not have a value in the Production Event Code field? |

NPECD = (Σ Losses where the Production Event value is populated but the associated Production Event contains no Production Event Code / Σ All MSC Values) x 100 |

The sum of losses where the Production Event comes from a Production Event whose Production Event Code field is null is 31,220. The sum of all MSC values is 483,910. Therefore:

|

| <Production Event Code Name> | Production Event Code | What percentage of loss is not associated with a given <Production Event Code>? |

<Production Event Code Name> = (Σ All Losses where the Production Event Code value is <Production Event Code Name> / Σ All MSC Values) x 100 Note: The colors that are used to represent the Production Event Codes come from the Color field in Production Event Codes.

|

The sum of losses where the Production Event comes from a Production Event whose Production Event Code field is null is 31,220. The sum of all MSC values is 483,910. Therefore:

|

| <Impact Code Name> | Impact Code | What percentage of loss is associated with a given <Impact Code>? |

<Impact Code Name> = (Σ All Losses where the Impact Code value is <Impact Code Name> / Σ All MSC Values) x 100 Note: The colors that are used to represent the Impact Codes come from the Color field in Impact Codes.

|

The sum of losses where the Impact Code value is TADD is 10,000. The sum of all MSC values is 65,000. Therefore:

|

| No Impact Code Defined | Impact Code | What percentage of losses are missing an Impact Code? |

NICD = (Σ Losses where the Impact Code value is null / Σ All MSC Values) x 100 |

The sum of losses where the Impact Code value is null is 2,000. The sum of all MSC values is 65,000. Therefore:

|

| <OEE Code Name> | OEE Code |

<OEE Code Name> = (Σ All Losses where the OEE Code value is <OEE Code Name> x Σ All MSC Values) x 100 |

The sum of losses where the OEE Code is Unscheduled Downtime is 10,000. The sum of all MSC values is 65,000. Therefore:

| |

| No OEE Code Defined | OEE Code | What percentage of losses are missing an OEE Code? |

NOCD = (Σ Losses where the OEE Code value is null / Σ All MSC Values) x 100 |

The sum of losses where the OEE Code value is null is 4,000. The sum of all MSC values is 65,000. Therefore:

|

| Idle Time Loss | OEE Code | What the percentage of time is the production unit Idle? |

Idle Time Loss = (Σ All Losses where the OEE Code value is under Idle Time / Σ All MSC Values) x 100 |

The sum of losses where the OEE Code value is under Idle Time is 4,000. The sum of all MSC values is 65,000. Therefore:

|

| Availability Loss | OEE Code | What percentage of scheduled production time is the production unit mechanically available? |

Availability Loss = (Σ All Losses where the OEE Code value is under Availability / Σ All MSC Values) x 100 |

The sum of losses where the OEE Code value is under Availability is 4,000. The sum of all MSC values is 65,000. Therefore:

|

| Performance Loss | OEE Code | What is the efficiency of the production unit? |

Performance Loss = (Σ All Losses where the OEE Code value is under Performance / Σ All MSC Values) x 100 |

The sum of losses where the OEE Code value is under Performance is 4,000. The sum of all MSC values is 65,000. Therefore:

|

| Quality Loss | OEE Code | What percentage of scheduled production time is the production unit producing products that met 1st run quality requirements? |

Quality Loss = (Σ All Losses where the OEE Code value is under Quality / Σ All MSC Values) x 100 |

The sum of losses where the OEE Code value is under Quality is 4,000. The sum of all MSC values is 65,000. Therefore:

|

| <Availability OEE Code Name> |

OEE Code (Availability) | What percentage of loss is associated with a given <Availability OEE Code>? |

<Availability OEE Code Name> = [Σ All Losses where the OEE Code value is <Availability OEE Code Name> / (Σ All Actual Values + Σ All Losses where the OEE Code value is under Availability + Σ All Losses where the OEE Code value is under Performance + Σ All Losses where the OEE Code value is under Quality)] x 100 |

The sum of losses where the OEE Code is Unscheduled Downtime is 10,000. The sum of (All Actual Values + All Losses where the OEE Code value is under Availability + All Losses where the OEE Code value is under Performance + All Losses where the OEE Code value is under Quality is 65,000. Therefore:

|

| <Performance OEE Code Name> |

OEE Code (Performance) | What percentage of loss is associated with a given <Performance OEE Code>? |

<Performance OEE Code Name> = [Σ All Losses where the OEE Code value is <Performance OEE Code Name>)/(Σ All Actual Values + Σ All Losses where OEE Code value is under Performance + Σ All Losses where OEE Code value is under Quality)] x 100 |

The sum of losses where the OEE Code is Minor Stops is 10,000. The sum of all (All Actual Values + All Losses where OEE Code value is under Performance + All Losses where OEE code value is under Quality) is 65,000. Therefore:

|

| <Quality OEE Code Name> |

OEE Code (Quality) | What percentage of loss is associated with a given <Quality OEE Code>? |

<Quality OEE Code Name> = [Σ All Losses where the OEE code value is <Quality OEE Code Name>/(Σ All Actual Values + Σ All Losses where the OEE Code value is under Quality)] x 100 |

The sum of losses where the OEE Code is Startup Rejects is 10,000. The sum of all (Actual Values + Losses where the OEE Code value is under Quality) is 65,000. Therefore:

|

| OEE - Availability | OEE Code (Availability) | What percentage of time was the production unit Mechanically Available to produce products? |

OEE Code - Availability = [(Σ All Actual Values + Σ All Losses where OEE Code value is under Performance + Σ All Losses where OEE Code value is under Quality)/(Σ All Actual Values + Σ All Losses where OEE Code value is under Availability + Σ All Losses where OEE Code value is under Performance + Σ All Losses where OEE Code value is under Quality)] x 100 |

The sum of all Actual values is 10,000. The sum of all losses where the OEE Code is under Performance is 2,000. The sum of all losses where the OEE Code is under Quality is 1,000. The sum of all losses where the OEE Code is under Availability is 3,000. Therefore:

|

| OEE - Performance | OEE Code (Performance) | What is the efficiency of the production unit for the time that production was scheduled? |

OEE Code - Performance = [(Σ All Actual Values + Σ All Losses where OEE Code value is under Quality)/(Σ All Actual Values + Σ All Losses where OEE Code value is under Performance + Σ All Losses where OEE Code value is under Quality)] x 100 |

The sum of all Actual values is 10,000. The sum of all losses where the OEE Code is under Performance is 2,000. The sum of all losses where the OEE Code is under Quality is 1,000. Therefore:

|

| OEE - Quality | OEE Code (Quality) | What percentage of 1st run quality products were produced? |

OEE Code - Quality = [Σ All Actual Values / (Σ All Actual Values + Σ All Losses where OEE Code value is under Quality)] x 100 |

The sum of all Actual values is 10,000. The sum of all losses where the OEE Code is under Quality is 1,000. Therefore:

|