Examples

Example of a Concurrent Quantity-Based Plan

This topic includes an example of a concurrent quantity-based Production Plan.

The following image shows a concurrent quantity-based Production Plan.

The data used in each of the sections is listed in tables. In the tables, we list only the fields that contain a value. The information in these tables is provided for your reference.

Production Profile Data

The example assumes that the PLA Administrator has added the following two Production Profiles to the Production Unit for which you want to create a concurrent quantity-based Production Plan:

| Field | Value |

|---|---|

| Product 1 | |

| Product | Diesel |

| Product UOM | Barrels |

| Production Rate UOM | Day |

| Standard Batch Size | 23,000 |

| Standard Batch Cycle Time | 1 |

| Max Sustained Capacity Rate | 23,000 |

| Product 2 | |

| Product | Gasoline |

| Product UOM | Barrels |

| Production Rate UOM | Day |

| Standard Batch Size | 103,700 |

| Standard Batch Cycle Time | 1 |

| Max Sustained Capacity Rate | 103,700 |

Production Summary

The example of a concurrent quantity-based Production Plan assumes that your Production Plan meets the following criteria:

| Criteria | Data Used in This Example |

|---|---|

| How Much |

Two Products:

|

| When | April 1, 2017 through April 18, 20167 |

| During Which Hours |

Monday through Friday, 24 hours per day, two shifts:

|

| How Often You Enter Data | Per Day |

| Production Model | Concurrent |

Example of a Concurrent Time-Based Plan

This topic includes an example of a concurrent time-based Production Plan.

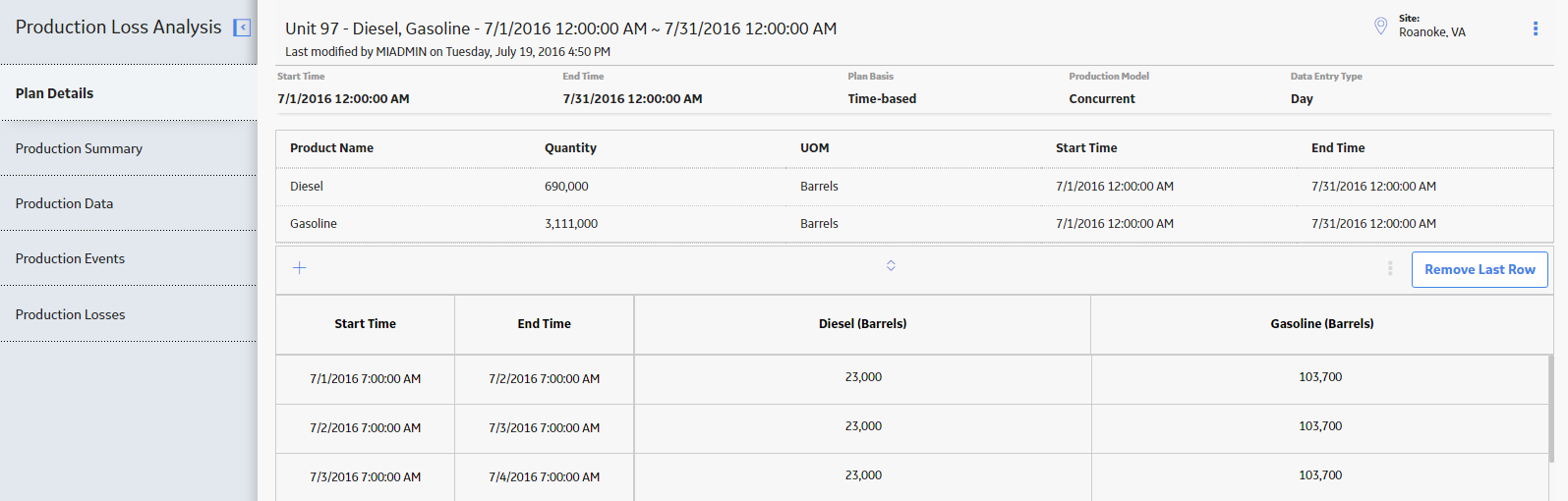

The following image shows a sequential time-based Production Plan.

The data used in this example is listed in tables. In the tables, we list only the fields that contain a value. The information in tables is provided for your reference.

Production Profile Data

The example assumes that the PLA Administrator has added the following two Production Profiles to the Production Unit for which you want to create a concurrent time-based Production Plan:

| Field | Value |

|---|---|

| Product 1 | |

| Product | Diesel |

| Product UOM | Barrels |

| Production Rate UOM | Day |

| Standard Batch Size | 23,000 |

| Standard Batch Cycle Time | 1 |

| Max Sustained Capacity Rate | 23,000 |

| Product 2 | |

| Product | Gasoline |

| Product UOM | Barrels |

| Production Rate UOM | Day |

| Standard Batch Size | 103,700 |

| Standard Batch Cycle Time | 1 |

| Max Sustained Capacity Rate | 103,700 |

Production Summary

The example of a concurrent time-based Production Plan assumes that your Production Plan meets the following criteria:

| Criteria | Data Used in This Example |

|---|---|

| How Much |

Two Products:

|

| When | July 1, 2016 through July 31, 2016 |

| During Which Hours |

Monday through Friday, 24 hours per day, two shifts:

|

| How Often You Enter Data | Per Day |

| Production Model | Concurrent |

Example of a Sequential Time-Based Plan

This topic includes an example of a sequential time-based Production Plan.

The following image shows a sequential time-based Production Plan.

Production Profile Data

The example assumes that the PLA Administrator has added the following two Production Profiles to the Production Unit for which you want to create a sequential time-based Production Plan:

| Field | Value |

|---|---|

| Product 1 | |

| Product | Diesel |

| Product UOM | Barrels |

| Production Rate UOM | Day |

| Standard Batch Size | 23,000 |

| Standard Batch Cycle Time | 1 |

| Max Sustained Capacity Rate | 23,000 |

| Product 2 | |

| Product | Gasoline |

| Product UOM | Barrels |

| Production Rate UOM | Day |

| Standard Batch Size | 103,700 |

| Standard Batch Cycle Time | 1 |

| Max Sustained Capacity Rate | 103,700 |

Plan Summary

The example of a sequential time-based Production Plan assumes that your Production Plan meets the following criteria:

| Criteria | Data Used in This Example |

|---|---|

| How Much |

Two Products:

|

| When |

|

| During Which Hours |

Monday through Friday, 24 hours per day, two shifts:

|

| How Often You Enter Data | Per Day |

| Production Model | Sequential |