PLA Plan Data Loader

About the Production Loss Analysis (PLA) 3-Plan Data Loader

Using the Production Loss Analysis (PLA) 3-Plan Data Loader, you can create the following records:

- Production Plans

- Production Data

- Production Losses

About the Production Loss Analysis (PLA) 3-Plan Data Loader Requirements

- Impact Code

- OEE Code

- Production Event

- Production Profile

- Production Unit

You can use the Production Loss Analysis (PLA) 1-Admin and Production Loss Analysis (PLA) 2-Event Data Loaders to create the Production Event, Production Profile, and Production Unit records. You must, however, load them in the following sequence:

Production Loss Analysis (PLA) 1-Admin

Production Loss Analysis (PLA) 2-Event

Security Settings

The user who loads data must be associated with the following Security Groups and Security Roles:

-

MI Data Loader User Security Role

-or-

MI Data Loader Admin Security Role

-

MI Production Loss Accounting Administrator Security Group

-or-

A Security Role that is associated with the MI Production Loss Accounting Administrator Security Group

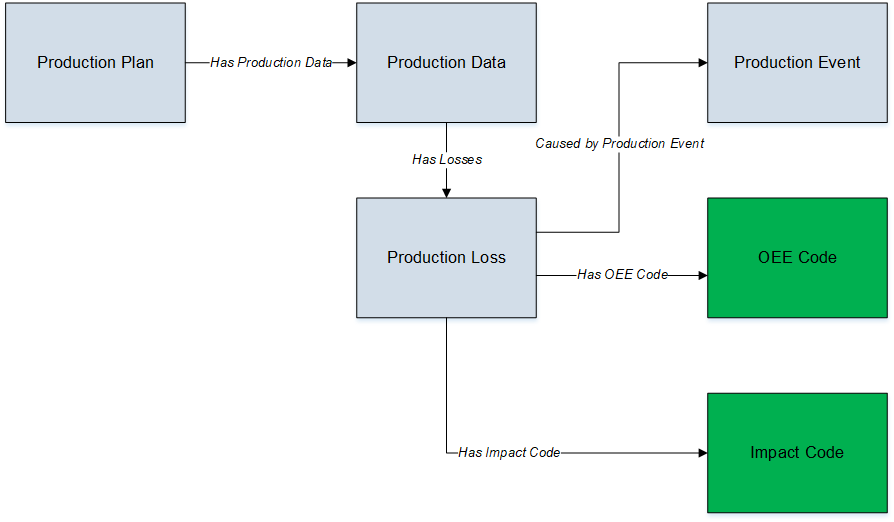

About the Production Loss Analysis (PLA) 3-Plan Data Loader Data Model

The following data model illustrates which records are supported by the Production Loss Analysis (PLA) 3-Plan Data Loader:

- Elements shown in grey are imported into GE Digital APM by the Production Loss Analysis (PLA) 3-Plan Data Loader.

- Elements shown in green exist in GE Digital APM and may be related to the data that is being loaded.

About the Production Loss Analysis (PLA) 3-Plan Data Loader General Loading Strategy

Best Practices

When using the Production Loss Analysis (PLA) 3-Plan data loader workbook, ensure that:

- The ID fields (that is, row 2) in each worksheet do not include special characters or spaces.

- Columns of each worksheet, including those representing custom fields, are not formatted as Text.

- The first two rows of each worksheet are not modified.

Modification Requirements and Guidelines

To accommodate a new or an enhanced feature, GE Digital APM may modify the data model from one version to the next. In this scenario, the data loaders will be modified and maintained by GE Digital APM between releases.

Limitations

- If you reimport a record that currently exists in GE Digital APM, the newly imported record will replace the existing one in GE Digital APM. The Production Loss Analysis (PLA) 1-Admin Data Loader does not create a duplicate record.

- You must not modify the template of the data loader workbook.

Load Sequence

- Download the Production Loss Analysis (PLA) 3-Plan data loader workbook provided by GE Digital APM:

- Identify the data requirements for exporting data from the legacy system into the data loader workbooks.

- Extract data from the legacy system to populate the data loader workbooks.

- Load data using the Production Loss Analysis (PLA) 3-Plan data loader workbook.

- Monitor the status of the data load operation and report results.

- Conduct tests in GE Digital APM to ensure that the imported data is loaded properly.

About the Production Loss Analysis (PLA) 3-Plan Data Loader Workbook Layout and Use

To load data using the Production Loss Analysis (PLA) 3-Plan Data Loader, GE Digital APM provides an Excel workbook, Production Loss Analysis (PLA) 3-Plan.xlsx, which supports baseline PLA in GE Digital APM.

The following table provides a list of worksheets that are included in the Production Loss Analysis (PLA) 3-Plan data loader workbook.

|

Worksheet |

Description |

|---|---|

| ProductionPlan |

This worksheet is used to specify the Production Plan records. |

| PlanDetails |

This worksheet is used to specify the Production Plan and Production Data records. |

| ProductionLoss | This worksheet is used to specify the Production Loss records. |

Color Coding

Certain columns in the worksheets have different functions and requirements. To illustrate this, they are color-coded. The following table provides a list of colors and what they represent.

|

Color |

Description |

Comments |

|---|---|---|

|

|

Fields with Special Notes |

Indicates columns that contain values that are used by the Production Loss Analysis (PLA) 3-Plan Data Loader to create records. If these columns are removed from the worksheets, the data load operation will fail. While the worksheets require that these columns be present, values are not necessarily required in these columns. |

|

|

Required Fields |

Indicates columns that contain values that are required in PLA. |

|

|

Recommended Fields |

Indicates columns that, according to GE Digital Best Practice for PLA, should contain values. |

|

|

Optional |

Indicates columns where you can specify custom fields. |

ProductionPlan Worksheet

Production Plan records store information about the quantity of Product you plan to produce within a certain period. In the ProductionPlan worksheet, you will specify the Production Plan records that you want to create.

|

Field Caption |

Field ID |

Data Type (Length) |

Comments |

|---|---|---|---|

| Plan Key | MI_PRDNPLAN_KEY | Character (255) | This cell is required. Enter a unique value. |

| Production Unit ID | MI_PRDNUNIT_Id | Character (255) |

This cell is required. The name of the Production Unit is case-sensitive. Other worksheets within the workbook can reference the Production Unit using this value. |

| Profile IDs | MI_PRDNPROF_IDs | Character (255) |

This cell is required. Based on the type of Production Plan, enter a value in one of the following formats:

To specify multiple Profile IDs, separate them using commas. |

| Plan Basis (TimeOr QuantityOrManual) | MI_PRDNPLAN_PLAN_BASIS_C | Character (255) |

This cell is required. Enter one of the following values:

|

| Data Entry Frequency | MI_PRDNPLAN_DATA_ENTR_FREQ_C | Character (255) |

This cell is required. Enter one of the following values:

|

| Start Date | MI_PRDNPLAN_START_DATE_D | Date | This cell is required. Enter a value in the following format: YYYY-DD-MM hh:mm:ss. |

| End Date | MI_PRDNPLAN_END_D | Date | This cell is required. Enter a value in the following format: YYYY-DD-MM hh:mm:ss This value must be greater than the Start Date. |

| Production Model (SequentialOr Concurrent) | MI_PRDNPLAN_PRODU_MODEL_C | Character (255) |

This cell is required. Enter one of the following values:

|

| Shift Details (shift for one of the days is required) | Monday | Character (255) | This cell is recommended.

|

| Tuesday | |||

| Wednesday | |||

| Thursday | |||

| Friday | |||

| Saturday | |||

| Sunday |

PlanDetails Worksheet

In the PlanDetails worksheet, you will specify the plan details for the Production Plan and Production Data.

|

Field Caption |

Field ID |

Data Type (Length) |

Comments |

|---|---|---|---|

| Plan Key | MI_PRDNPLAN_KEY | Character (255) | This cell is required. Enter the key that is assigned to the Production Plan that you want to reference. The ProductionPlan worksheet contains this value. |

| Production Unit ID | MI_PRDNUNIT_Id | Character (255) |

This cell is required. Enter the ID that is assigned to the Production Unit that you want to reference. The ProductionPlan worksheet contains this value.

|

| Production Profile ID | MI_PRDNPROF_ID | Character (50) | This cell is required. Enter the Product Alias Name. |

| Line Number | MI_PRDNDATA_PLAN_DETAIL_ID_N | Numeric | This cell is required. Enter a value that is unique within a Production Plan Key, Production Unit ID, and Production Profile ID. |

| Shift Start Date Time | MI_PRDNDATA_PERIOD_D | Date | This cell is required. Enter a value in the following format: YYYY-MM-DD hh:mm:ss. |

| Shift End Date Time | MI_PRDNDATA_END_TIME_D | Date | This cell is required. Enter a value in the following format: YYYY-MM-DD hh:mm:ss. |

| Planned Production | MI_PRDNDATA_USEF_PROD_TIME_N | Numeric | This cell is optional. Enter the quantity of the product that is planned to be produced in the defined period. It is measured in terms of Product UOM (for example, 50 Barrels). |

| Short Range Plan | MI_PRDNDATA_SHTRNG_PLAN_N | Numeric | This cell is optional. Enter a short-range planning value if it is to be used as a baseline for losses. It is measured in terms of Product UOM (for example, 50 Barrels). |

| Actual | MI_PRDNDATA_ACTUAL_N | Numeric | This cell is optional. Enter the actual production recorded in the defined period. It is measured in terms of Product UOM (for example, 50 Barrels). |

| MSCR | MI_PRDNDATA_RATED_N | Numeric | This cell is required. Enter the maximum sustained capacity rate. It is measured in terms of Product UOM per Production Rate UOM (for example, 50 Barrels/Day). |

| MSHR | MI_PRDNDATA_MSHR_N | Numeric | This cell is recommended. Enter the Maximum Sustained Hourly Rate (MSHR) to be applied to losses to calculate Estimated Downtime Hours (EDT). If a value is not entered, the EDT field will appear blank in the corresponding Production Plan. It is measured in terms of Product UOM (for example, 50 Barrels). |

ProductionLoss Worksheet

Production Loss records store information about the loss of production caused by an event. In the ProductionLoss worksheet, you will specify the Production Loss records that you want to create.

|

Field Caption |

Field ID |

Data Type (Length) |

Comments |

|---|---|---|---|

| Plan Key | MI_PRDNPLAN_KEY | Character (255) | This cell is required. Enter the key that is assigned to the Production Plan that you want to reference. The ProductionPlan worksheet contains this value. |

| Production Unit ID | MI_PRDNUNIT_Id | Character (255) |

This cell is required. Enter the ID that is assigned to the Production Unit that you want to reference. The ProductionPlan worksheet contains this value.

|

| Production Profile ID | MI_PRDNPROF_ID | Character (50) | This cell is required. Enter the Product Alias Name. |

| Line Number | MI_PRDNDATA_PLAN_DETAIL_ID_N | Numeric | This cell is required. Enter a value that is unique within a Production Plan Key, Production Unit ID, and Production Profile ID. |

| Impact Code | MI_PRDNLOSS_IMPACT_CODE_C | Character (255) | This cell is optional. Enter a value that matches an existing Impact Code in GE Digital APM. |

| Loss Amount | MI_PRDNLOSS_LOSS_AMOUNT_N | Numeric | This cell is optional. Enter the amount of losses incurred. It is measured in terms of dollars. |

| OEE Code | MI_PRDNLOSS_OEE_CODE_C | Character (255) | This cell is optional. Enter a value that matches an existing OEE Code in GE Digital APM. |

| Comment | MI_PRDNLOSS_COMMENT_C | Character (255) | This cell is optional. Enter a value to describe the loss. |

|

Event Id | MI_PRDNLOSS_PRDN_EVENT_C | Character (250) | This cell need not have a value; however, the column must exist in the worksheet. Enter the Event ID of the Production Event. |

| Margin Id | MI_MARGIN_ID | Character (50) | This cell is optional. Enter the Margin ID of the Profile Margin. |

| EDT | MI_PRDNLOSS_EDT_N | Numeric | This cell is recommended. Enter the estimated downtime. It is measured in hours. |

About the Production Loss Analysis (PLA) 3-Plan Data Loader Load Verification

About This Task

After you load data, you can access the Production Event records. In a successful import, all the calculations that are based on the imported data must be correct to the degree of accuracy specified in the Settings window in the PLA Administrator page.

You should perform the following steps in GE Digital APM to confirm the accuracy and integrity of the data imported from the data loader workbook:

Procedure

- Access the details of the import job. In addition to the general information regarding the records that were loaded during the data load operation, these details may include error and warning messages pertaining to the records.

- In PLA, access the records specified in the data loader workbook, and then verify that the expected data is present or updated, as applicable.