Orlando Utilities Commission Improves Collaboration Through Intuitive SCADA Visualization

Learn how Orlando Utilities Commission in Florida strengthened collaboration and eased water compliance reporting by transforming HMI/SCADA with…

Water/Wastewater

Watch this AWWA webinar to see how water engineers can use self-serve analytics to solve their toughest challenges. Our hero of the show is a mid-sized water utility, that partnered with GE Vernova to predict pump failure up to 16 days in advance, using Proficy CSense.

Water utilities have no shortage of data – real time and historical, and the promise of analytics to harness this data is well documented and widely promoted. However, how does the hype compare with reality when it comes to non-data scientists using these tools and driving meaningful outcomes? The benefits are clear for analytics, mine your existing data to reap the rewards:

Proven processes and software technologies make analytics achievable for every industrial organization. Using analytics, engineers can combine data across industrial data sources and rapidly identify problems, discover root causes, predict future performance, and automate actions to continuously improve quality, ease compliance, and decrease chemical and energy consumption.

It’s time to put your industrial data to work. See analytics in action.

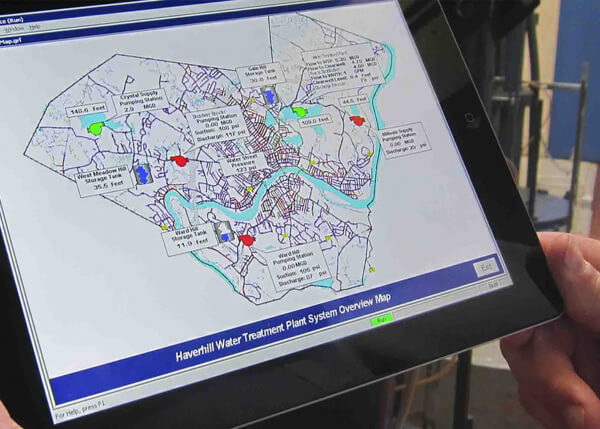

Aging infrastructure and growing water supply demand make increasing equipment availability and reliability crucial. Add managing security and risk at water treatment plants, reducing costs, and equipment failures and you can understand the difficulties facing today's water and wastewater utilities.

Learn how Orlando Utilities Commission in Florida strengthened collaboration and eased water compliance reporting by transforming HMI/SCADA with…

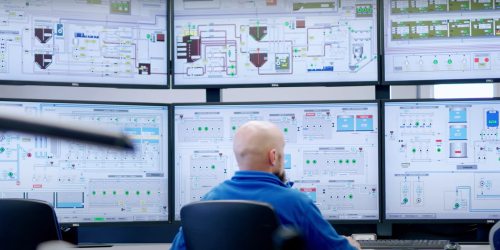

Learn how Racibórz Waterworks saves money and time with unified Enterprise SCADA.

Explore how the City of Hamilton enables remote workers and supervisors for seamless 24/7 operations using GE Vernova's iFIX HMI/SCADA.