Indonesia is the world’s fourth most populous nation, and a growth engine at the heart of Southeast Asia’s economy. The country is on track to become the world’s fourth largest economy by 2050.

To fuel this growth, the need for gas power is stronger than ever, specifically across critical sectors such as mining and metal processing, which serve as economic catalysts for the country.

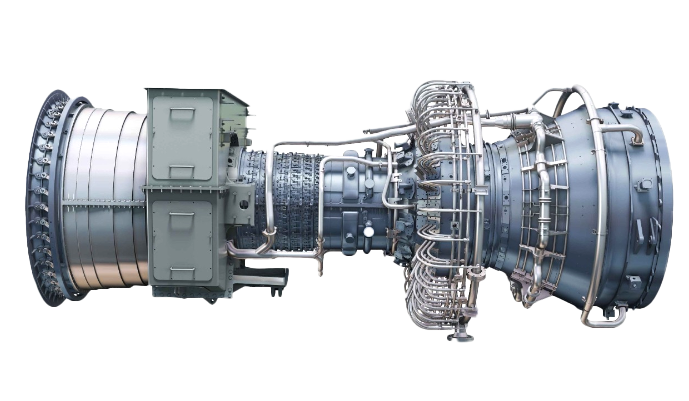

GE’s aeroderivative gas turbine fleet provides clean, reliable, and flexible power that rapidly adapts to changing operating conditions, backed by local and remote support teams that can easily respond to any operational disruption. That combination of responsive gas turbine technology and comprehensive support provides a solid foundation to power Indonesia’s economic growth.

Growing demand for flexible gas power in Indonesia

The International Energy Agency (IEA) predicted in 2019 that overall energy demand in Southeast Asia would grow by 60%, and electricity demand more than double, by 2040. Indonesia will be one of the key markets for that growth.

Economic growth will drive industrial and residential electricity demand. That means meeting the growing energy needs of a population of more than 260 million citizens spread over 18,000 islands and powering the nation’s economic needs with an average annual GDP growth of more than 5% will be critical.

The industry sector in Indonesia contributes a substantial 40% of the nation’s GDP. Industrial energy demand in Indonesia is expected to rise by over 70% in the next two decades.

The country's mining and metals processing will be an important focus of this activity, a commitment established in the first term of President Jokowi’s presidency. Indonesia is the world’s largest producer of nickel ore, and a push towards greater metal refining capacity is underway to add value to the country’s commodity exports. Meeting this target will require reliable industrial gas power solutions.

Indonesia is an archipelago country spread over thousands of islands. GE’s aeroderivative gas turbine technology is perfectly suited to that environment. It provides a modular solution that is easy to deploy in remote locations, and a perfect match for key industrial sectors such as Indonesia’s vital mining and smelting industries,” said George Djohan, Country Leader, GE Gas Power.

With more than 2,100 units shipped globally and over 150 million operating hours, GE’s aeroderivative gas turbines represent one of the most experienced technologies for global co-generation needs. The impressive operational flexibility delivers solutions for industries from mining and manufacturing to petrochemicals. That makes it a uniquely suitable solution for the industries central to Indonesia’s growing economy.

Operational flexibility with aeroderivative gas turbines

GE’s aeroderivative gas turbine portfolio delivers world-leading efficiency. The unique design of aeroderivative gas turbines allows them to produce high-quality steam in a high and medium pressure range, providing Indonesian citizens with a significantly lower heat-to-power ratio than heavy duty gas turbines for industrial combined heat and power (CHP) needs.

The aeroderivative portfolio covers power solutions from 30MW up to 130MW. The simple-cycle electric efficiency of these gas turbines reaches 43% at base load, and 50% at part-load power.

This flexibility also offers an important solution for Indonesia’s geographical challenges. GE’s TM2500 mobile power plant provided a flexible solution to deliver efficient, rapidly deployed power to the island of Lombok. A deal signed in 2015 saw 20 TM2500 units spread throughout Indonesia, delivering the capacity to power four million homes.

Aeroderivative gas turbines also help balance the challenges of Indonesia’s extensive transmission systems, providing distributed power at the load center, overcoming the technical difficulties of transmission over these distances. Aeroderivative gas turbines can deliver rapid power from a cold start in just five minutes. That means from blackout to lights-on as local demand requires.

These solutions offer an important economic enabler in Indonesia, where mining is an essential part of industrial activity. Indonesia produced over 50 million wet metric tonnes of nickel alone in 2019, with four new smelters bringing the total refining capacity in the country up to an estimated 69 million tonnes per year. An additional 52 smelters are planning to be built in the next 5 years, some are already under construction.

Aeroderivative gas turbines are designed to ensure low maintenance needs for Indonesian operators in these challenging environments, avoiding problems caused by repeated stop/ start operations of heavy-duty gas turbines. Aeroderivative gas turbines require just 1,800-man hours of maintenance during a three year-cycle, compared to 15,000-man hours for rival reciprocating engines.

GE’s LM6000 gas turbine has been delivering reliable power to a gold mine in Australia for over a decade. The local island grid represents many of the challenges of Indonesia’s industrial applications, meeting substantial load requirements in difficult operational conditions. A 2017 upgrade to the SPRINT water injection valve enabled fuel cost savings by helping meet power demand with less operational units running.

The flexible, modular, power-generating solutions provided by aeroderivative gas turbines allows mining operators to easily respond to changing on-site demands. Fast start-up and fast ramp-up creates a responsive power system that adapts to meet business needs, even in the most challenging operating environment.

Meeting industrial needs in an era of uncertainty for Indonesia

Maintenance burden is a key challenge in time-critical operating environments. These difficulties were highlighted during COVID-19, as lockdown restrictions caused significant delays in access to engineering workforces, as well as restricted shipping of parts to repairs in third-party countries.

At GE Gas Power, we not only support operations through real-time insight and virtual maintenance expertise from our global support centers but offer dedicated local services for customers. We strive to deliver timely support to ensure the regional fleet of 800+ gas turbines continue to operate to keep the lights on in the countries like Indonesia.

Comprehensive engineering support ensures resilience for ongoing operations of GE’s gas turbine customers. GE’s Remote Engineering Support Services are being provided to customers throughout Asia due to movement restrictions brought about by the COVID-19 pandemic, providing technical solutions from experts anywhere in the world, to help assets run reliably throughout this crisis, despite physical challenges in visiting sites. Our team of engineers provides real-time data analysis, expert evaluation, and optimization support for gas turbine assets.

Falling prices of natural gas further improve the economic case for aeroderivative gas turbines, as the fuel source which delivers highest efficiency operations for these technologies. Natural gas also provides a far less emissions-intensive operation, meeting strict industrial environmental standards, and contributing to the Indonesian Government’s commitment to reduce carbon emissions by 29% compared to businesses as usual levels by 2030

GE’s aeroderivative gas turbine portfolio offers reliable, efficient power with world-leading flexibility. At GE, we’re also committed to ensuring that our customers’ aeroderivative gas turbine assets run at optimal operating conditions in whatever environment they are deployed. GE Power’s investment in local and remote support provides expert technical solutions as and when customers need it. As we continue to power economic growth in Indonesia, reliability, flexibility, and resilience will be essential in supporting the nation’s success.