Search GE Gas Power

What are you looking for?

Or start with a popular search:

Recommended resources

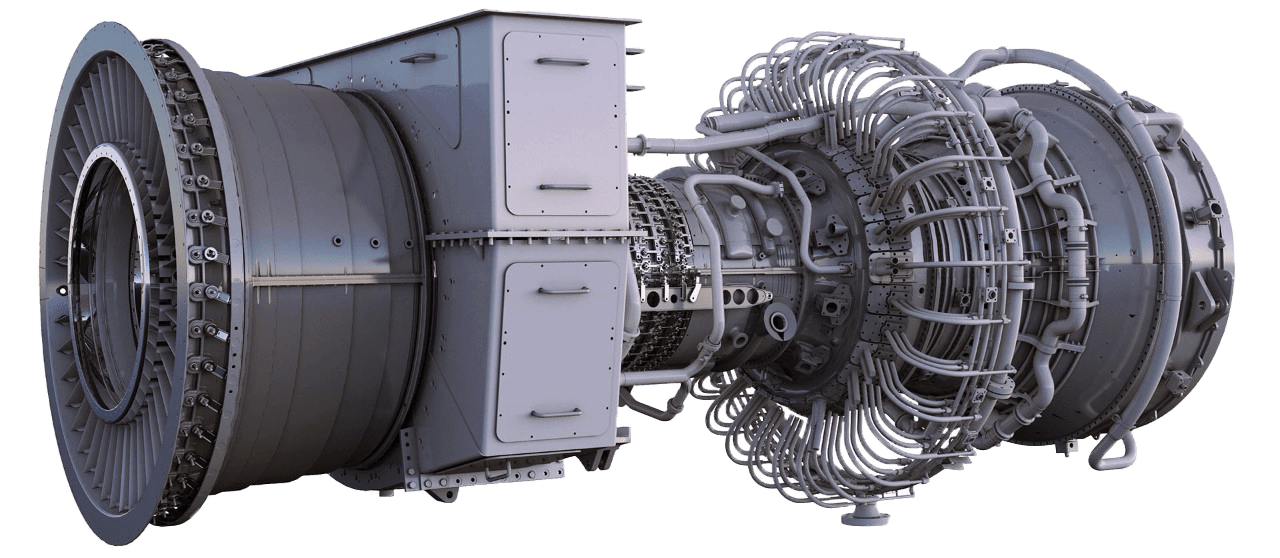

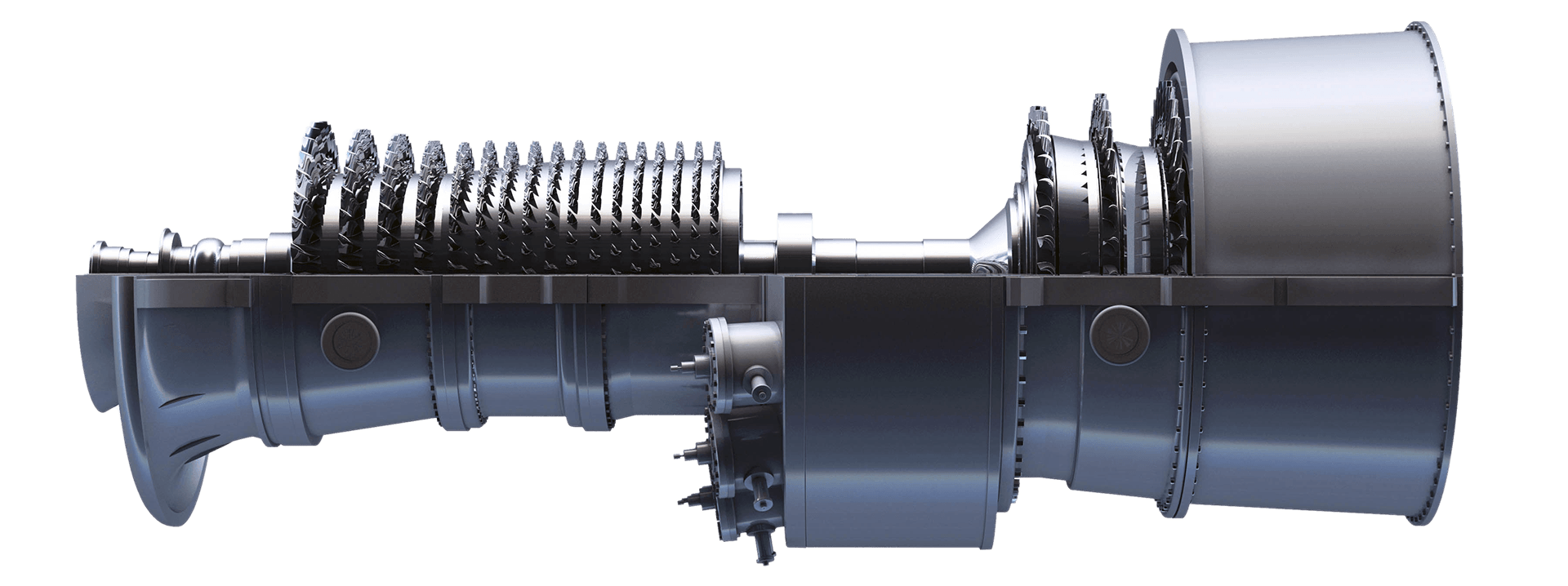

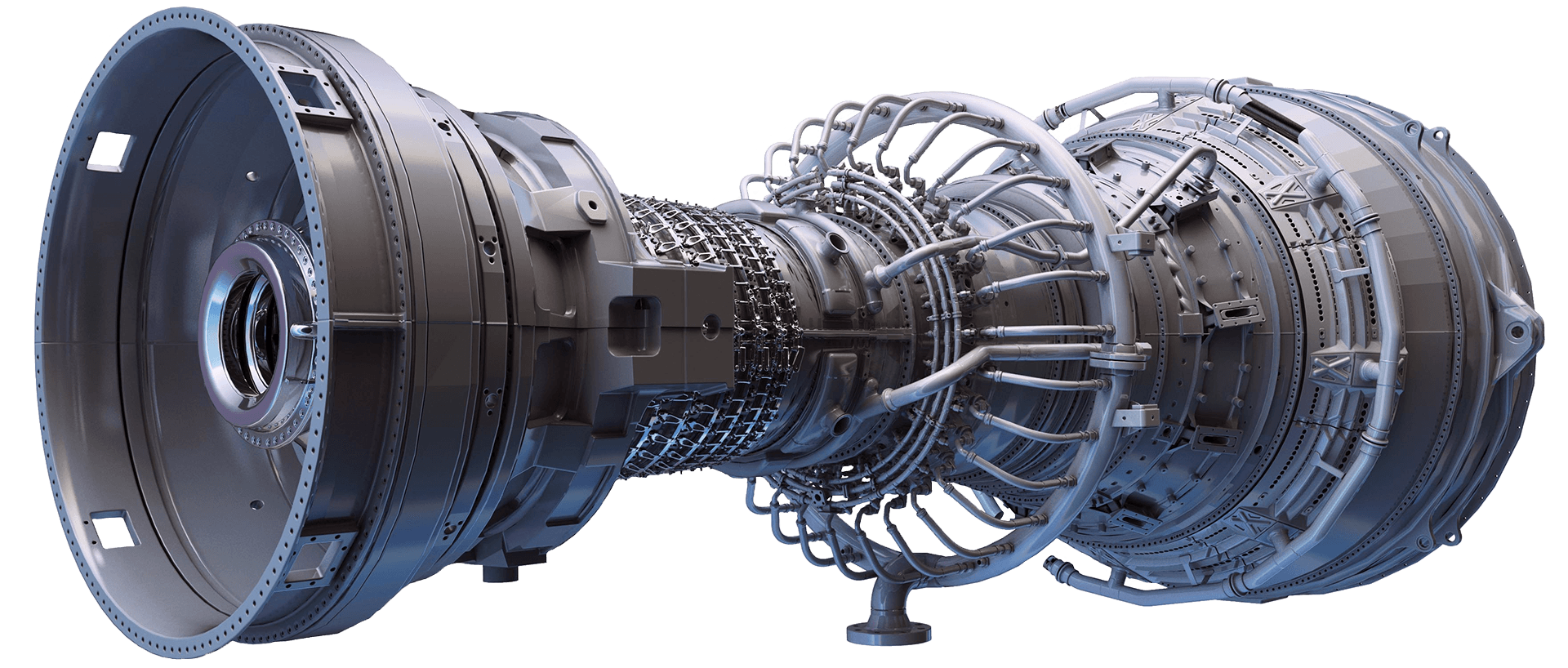

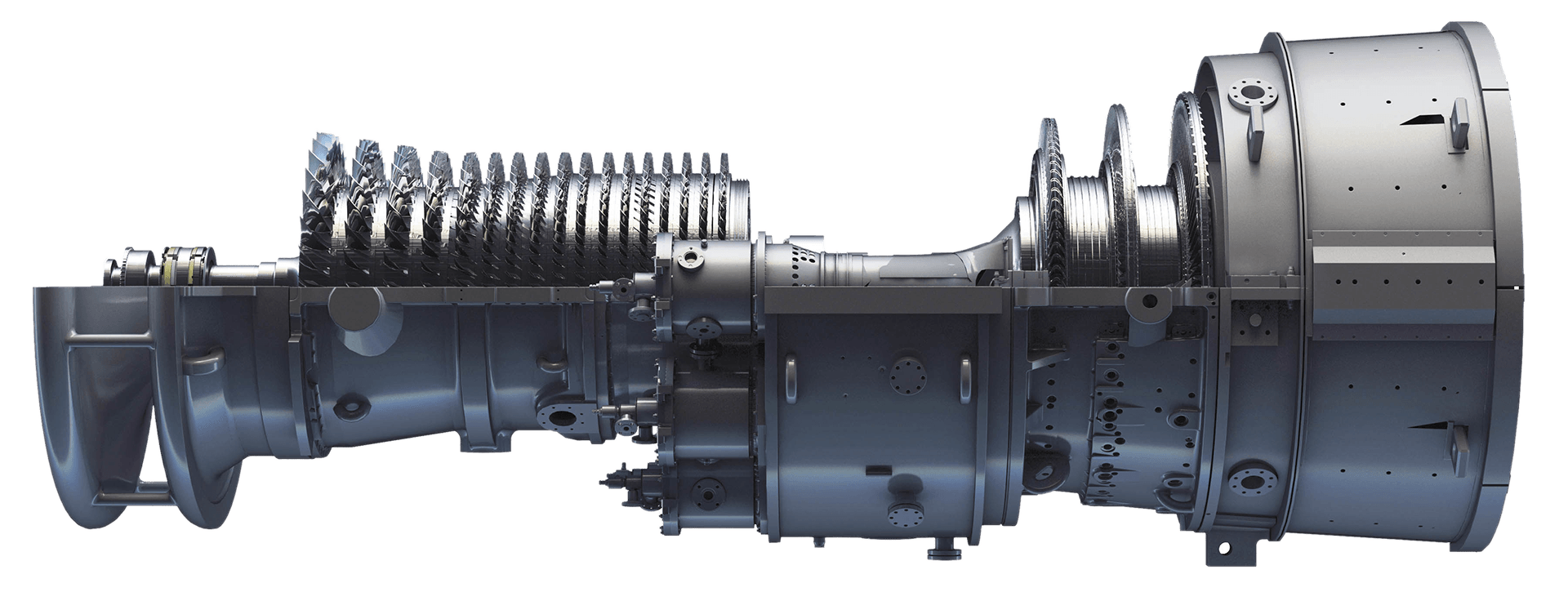

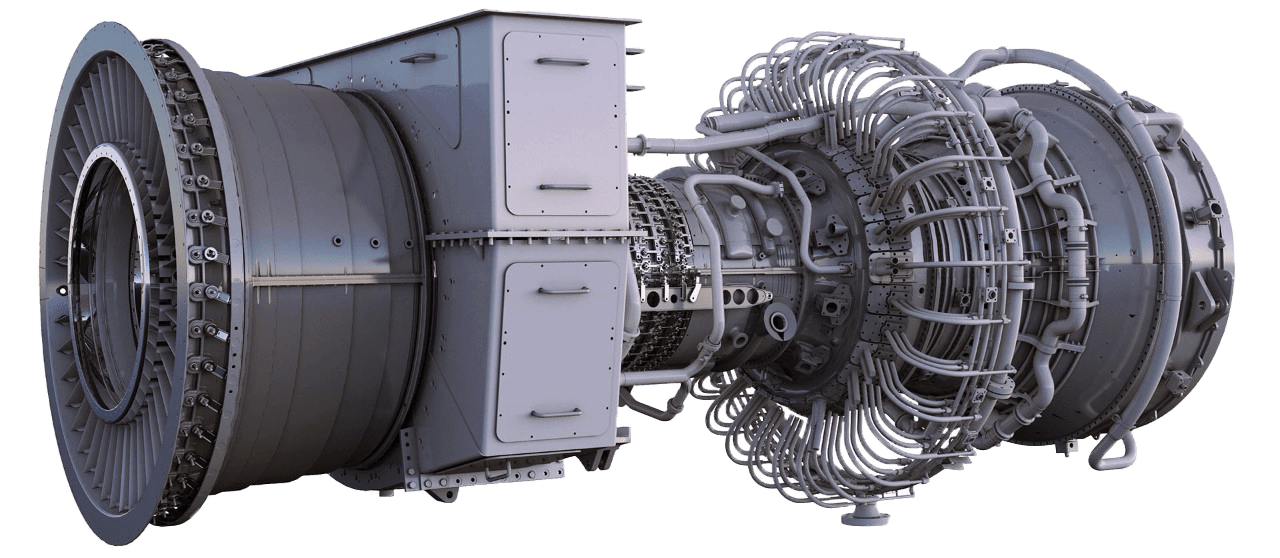

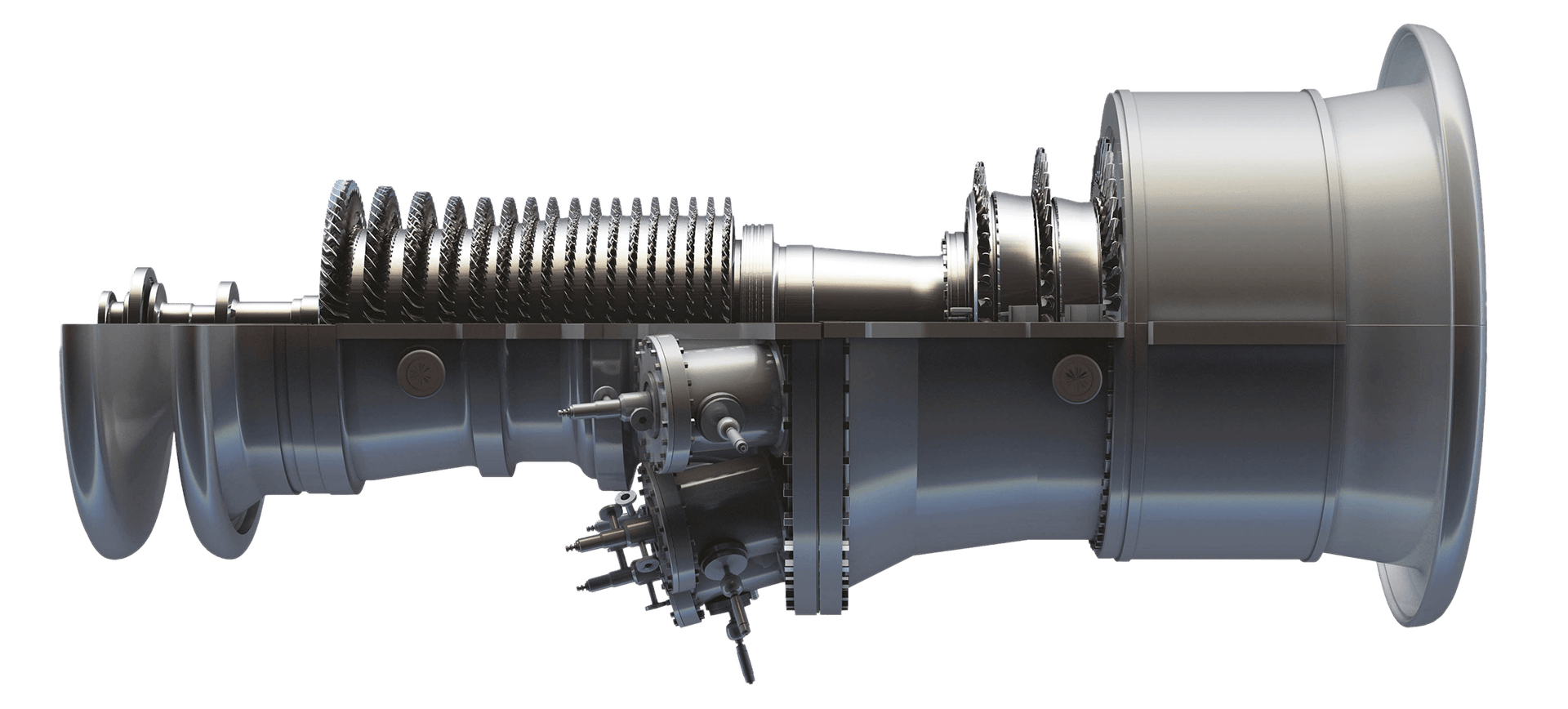

LM6000 aeroderivative gas turbine

A leader in the +40 MW space, the LM6000* has over 40 million operating hours and more than 1,200 units shipped.

57+ MW

GTG output

Up to 41.4%

net efficiency

Over 99/98%

reliability/availability

5 min.

start time

100% H2 capable

with zero CO2 emissions

Overview

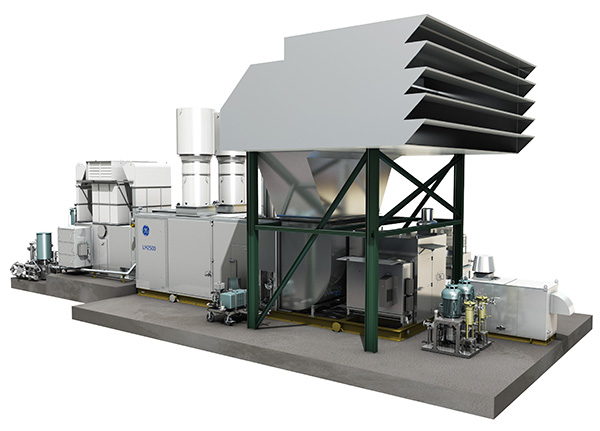

LM6000 power plants

With over 40 million operating hours and more than 1,200 units shipped, GE’s LM6000 aeroderivative gas turbine has more operating experience than any other aeroderivative gas turbine greater in the +40 MW space. The LM6000 offers greater than 99 percent start and operational reliability and over 98 percent availability. Its 5-minute fast start allows operators to differentiate their dispatch capability while a simple two-spool design results in lower overall maintenance costs. Universal and modular packaging gives the LM6000 a smaller footprint and allows for faster installation and commissioning.

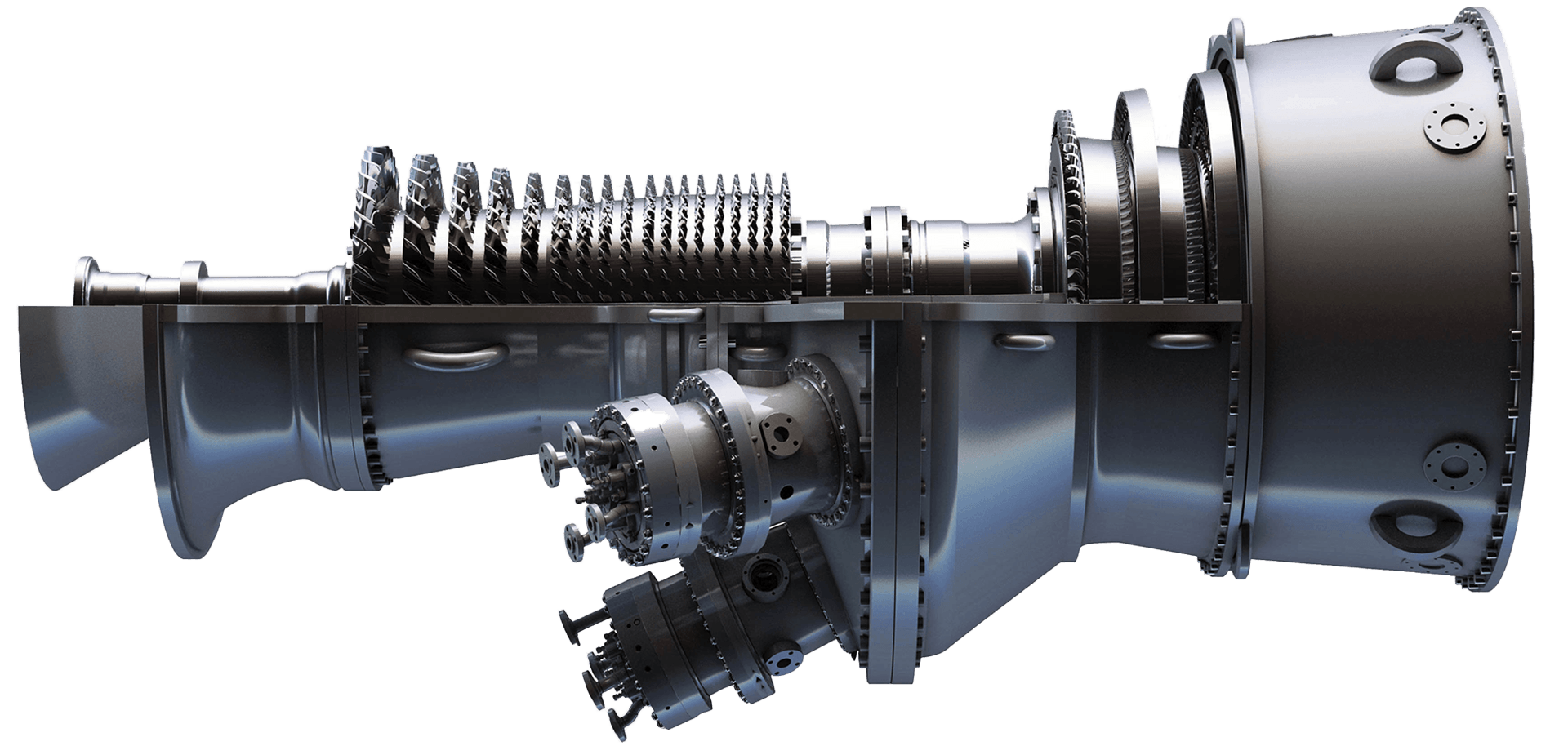

Faster power to the grid

Introducing the LM6000VELOX* aeroderivative solution

The new LM6000VELOX aeroderivative solution aims to reduce the installation and commissioning schedule of LM6000 turbines by up to 40%, saving up to 4,000 labor hours. This translates to an expected 90 days I&C schedule. Thanks to multiple enhanced modularity features, the LM6000VELOX aeroderivative solution is ushering in a new era of speed in the energy industry.

GE Vernova's LM6000VELOX aeroderivative solution is available:

- In both simple- and combined-cycle configurations.

- As either a DLE or SAC (water injected) combustor configuration.

- For both 50- and 60-Hertz segments.

Product features

Get to know the LM6000

Specifications

Capable, versatile, sustainable power

The LM6000 offers 99%+ start and operational reliability and 98% availability. Its 5-minute fast start allows operators to differentiate their dispatch capability, and its dual-fuel capabilities provides fuel flexibility and helps customers meet emissions limits.

Specifications shown are for 50 Hz and 60 Hz.

| LM6000 PC | LM6000 PG | LM6000 PF | LM6000 PF+ | |

|---|---|---|---|---|

| Net output (MW) | 46.6/51.1* | 56/57.2* | 44.7/50* | 53.9/57.1* |

| Net heat rate (Btu/kWh, LHV) | 8533 | 8728 | 8248 | 8357 |

| Net heat rate (kJ/kWh, LHV) | 9002 | 9208 | 8702 | 8817 |

| Net efficiency (%, LHV) | 40% | 39.1% | 41.4% | 40.8% |

| Ramp rate (MW/minute) | 30 | 30 | 30 | 30 |

| Startup time (cold iron) (min.) | 5 | 5 | 5 | 5 |

| GT Min. Turn Down Load (%) | 25% | 25% | 50% | 50% |

LM6000 gas turbines can start up in 5 minutes

*MW output without SPRINT/with SPRINT

NOTE: All ratings are based on ISO conditions and natural gas fuel. Actual performance will vary with project-specific conditions and fuel.

Featured webinar

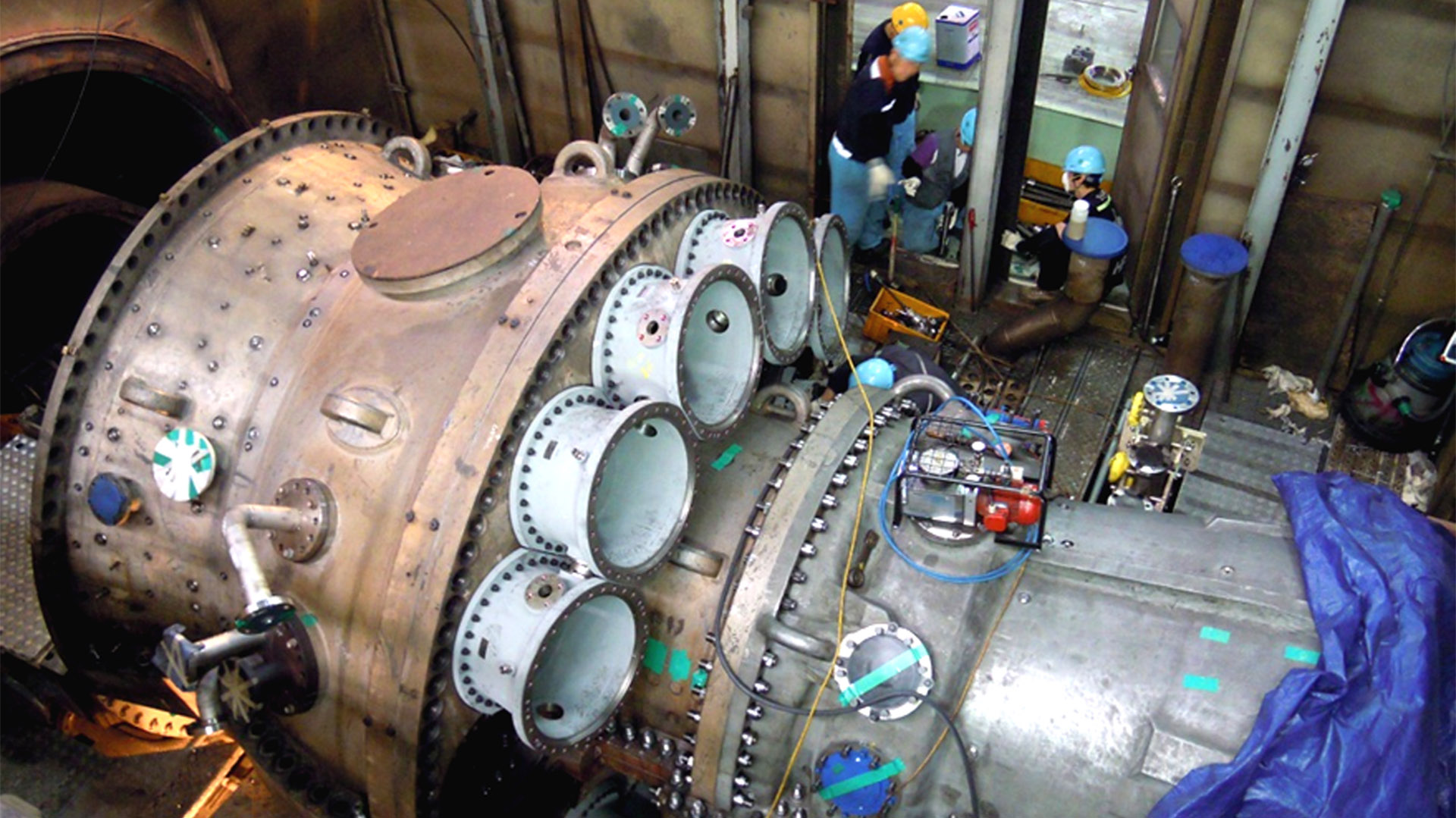

Aero Level-2 shops: Local service on a global scale

Join Mort Smith, Wayne Romeo, Robert Hammond, and our regional expert for Asia, Walter Pakai as they dive into the repair capabilities of our L2 shops for your aero fleet.

Webinars

Hear from our experts

- Fast, flexible, sustainable power: Aeroderivative gas turbines for Munis & Co-ops

- Municipalities and Co-ops: Can you get more megawatts for your dollar?

On-demand webinar

Fast, flexible, sustainable power: Aeroderivative gas turbines for Munis & Co-ops

Today’s energy transition is creating challenges for all power producers, from local municipalities and Co-ops to utilities of all sizes. Operators need to plan carefully to ensure grid reliability and faster, cheaper, cleaner power for their end users.

On-demand webinar

Aeros vs. recips: Simplicity in motion

As a plant operator, you’re always looking for ways to improve your site, and know that higher efficiency leads to lower costs. But what can you do to achieve this? Aeroderivative gas turbines offer many advantages over a reciprocal engine such as reliability and savings instead of maintenance and downtime.

Featured Video

LM6000 install in Germany: Meeting the challenge

Get an inside look at the 2019 LM6000 install at the Freimann Power Plant, where the GE team faced a number of challenges.

Customer stories

Hear from our customers

Germany

Providing flexible, agile power in Germany

2

LM6000 gas turbines

2030s

plan to integrate hydrogen

We like the flexibility of being able to run the units to generate heat that’s then kept in the storage system. And because the units can start up so quickly, it’s very simple for us to react spontaneously to gas or power prices.

Simon Weig

Plant manager, Freimann

Customer stories

Hear from our customers

Tennessee, USA

Improving gas turbine installation & commissioning costs

Up to 40%

reduction in the installation and commissioning schedule of LM6000 turbines

Up to 4,000

labor hours saved

"This technology will be the first of its kind for TVA’s fleet of natural gas plants. We have received six of the 10 total units that will be operating at Johnsonville, with final delivery expected in December, 2023. These units will help us quickly meet demand during peak energy usage and will supplement solar generation on days when sunshine is limited."

Justin McBath

Sr. Project Manager of the Johnsonville Aeroderivative Combustion Turbine Plant project, TVA

Customer stories

Hear from our customers

Game-changing results for a greener future

14%

reduction in CO2 emissions

~88%

overall drop in CO emissions

"NYPA is leading the way by piloting new approaches to accelerate New York State’s energy transition. Decarbonizing the power sector will require a collaborative, multi-pronged approach, including the use of renewable power. Today, NYPA is pleased to share the results of our joint hydrogen study with the industry, so that our key findings might illuminate the future of decarbonization.”

Justin E. Driscoll

New York Power Authority, Interim President & CEO

Customer stories

Hear from our customers

Texas, USA

Healthier operations in Texas

99/98%

reliability

5 minutes

startup to full power

"Reliability is priority one for TECO, with efficiency a close second. The LM6000 was installed to help ensure a reliable power supply in the event of a grid outage."

Mike Manoucheri

President and CEO of Thermal Energy Corporation (TECO)President and CEO of Thermal Energy Corporation (TECO)

Services

Get more from your LM6000 aero turbine

Our services team is prepared to meet your industry-specific requirements and provide more reliable aeroderivative gas turbine services whether you’re looking for peaking power, flexible response to immediate grid demands, or simply to keep your operation up and running at a proven 99% rate of reliability.

Further Reading

Learn more

Explore

Products

Find the right gas turbine to meet your needs

Whether you're generating power for entire cities, electrifying your own operations, or are facing an emergency electricity shortage and need power fast, we can act as a versatile gas turbine supplier, ready to quickly provide a range of solutions.

- 50Hz

- 60Hz

- Simple

- 1x1CC

- 2x1CC

- All

- Heavy duty

- Aeroderivative

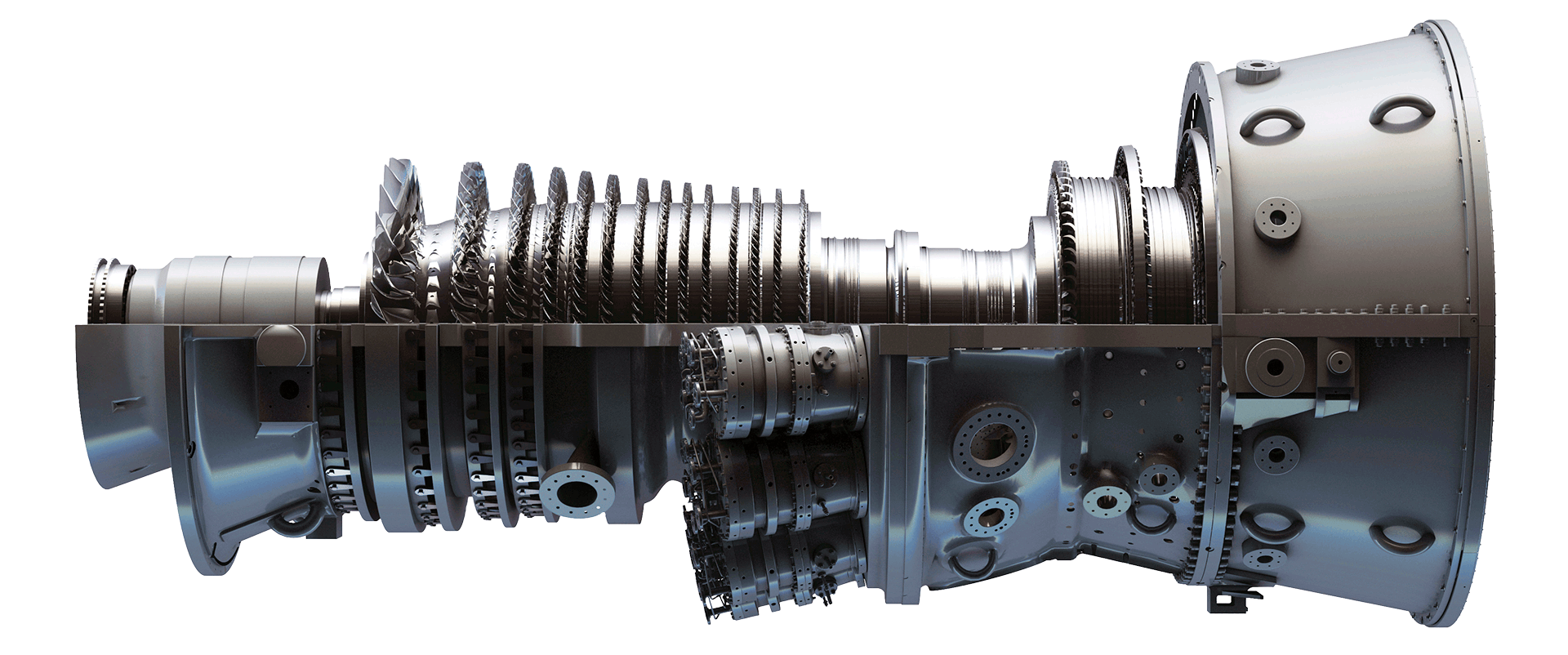

GE Vernova’s 9HA high efficiency, air-cooled gas turbine is one of the industry leaders among H-class offerings, and now the 9HA gas turbine is at the heart of the world's most efficient combined-cycle power plant.

| 9HA.01 | 9HA.02 | |

|---|---|---|

| Net output (MW) | ||

| Net heat rate (kJ/kWh, LHV) | ||

| Net efficiency (%, LHV) | ||

| Net heat rate (Btu/kWh, LHV) |

9HA gas turbines are 50% hydrogen (H2) capable with a technology pathway to 100%

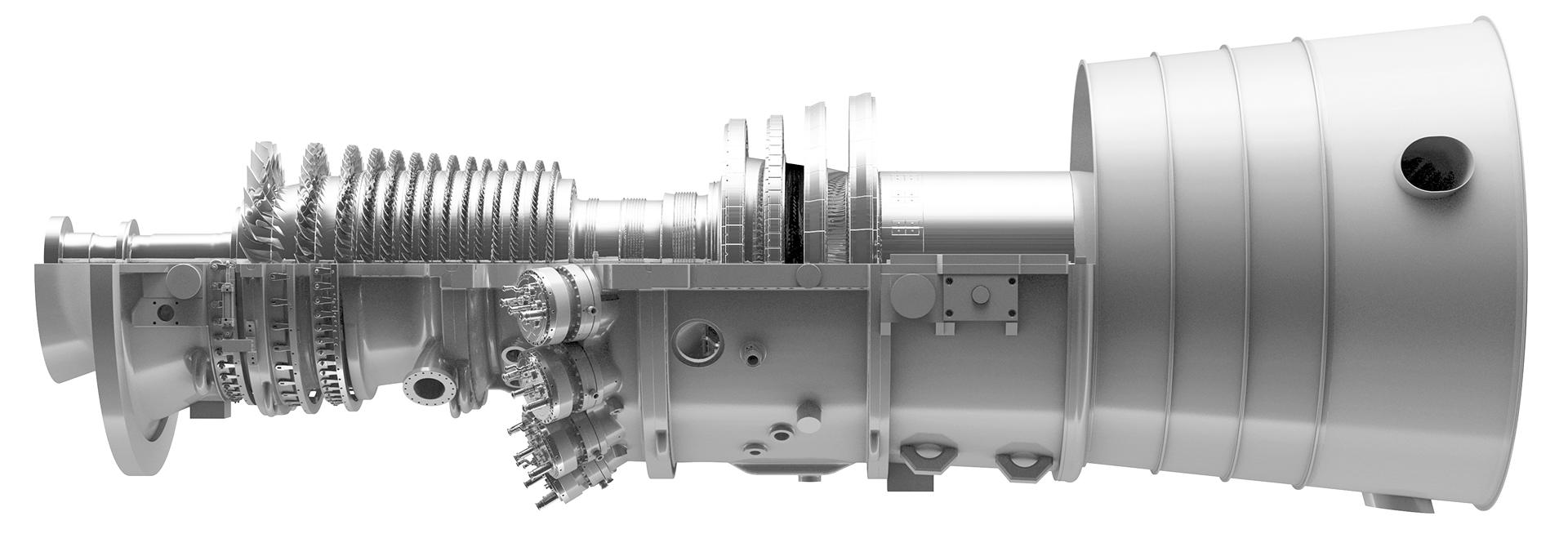

With over 450 units deployed to more than 40 countries, GE Vernova has the largest operating and most experienced OEM F-class fleet in the world. Our 9F gas turbine delivers consistent performance and accommodates a diverse range of fuels, making it great for a variety of combined cycle and CHP applications.

| 9F.04 | |

|---|---|

| Net output (MW) | |

| Net heat rate (kJ/kWh, LHV) | |

| Net efficiency (%, LHV) | |

| Net heat rate (Btu/kWh, LHV) |

9F series turbines are GE’s most advanced F-class technology for 50 Hz applications.

GE’s 7HA high efficiency air-cooled gas turbine is one of the industry leaders among advanced class gas turbine offerings and is available in three models—the 7HA.01 at 290 MW, the 7HA.02 at 384 MW, and the 7HA.03 at 430 MW.

| 7HA.01 | 7HA.02 | 7HA.03 | |

|---|---|---|---|

| Net output (MW) | |||

| Net heat rate (kJ/kWh, LHV) | |||

| Net efficiency (%, LHV) | |||

| Net heat rate (Btu/kWh, LHV) |

7HA gas turbines are up to 50% hydrogen (H2) capable with a technology pathway to 100%

The demands of today’s power generation industry are many: low cost of electricity, dispatch volatility, along with high efficiency, reliability, and asset availability. With approximately 950 installed units producing ~175GW of power in 11 countries, GE’s 7F.04 and 7F.05 gas turbines are proven performers in all these areas.

| 7F.04 | 7F.05 | |

|---|---|---|

| Net output (MW) | ||

| Net heat rate (kJ/kWh, LHV) | ||

| Net efficiency (%, LHV) | ||

| Net heat rate (Btu/kWh, LHV) |

7F series gas turbines can balance renewables by load-following at 40 MW/min ramp rates while maintaining emissions compliance.

With unprecedented operational flexibility, robust engineering and long operation intervals, the GT13E2 can be used in many different applications—all while meeting a very broad range of environment and operating conditions.

| GT13E2-190 | GT13E2-210 | |

|---|---|---|

| Net output (MW) | ||

| Net heat rate (kJ/kWh, LHV) | ||

| Net efficiency (%, LHV) | ||

| Net heat rate (Btu/kWh, LHV) |

GT13e2 gas turbines can run on up to 30% hydrogen fuel.

Formerly known as the Frame 9E, GE Vernova’s 9E gas turbine can help decrease costs and increase revenue for your plant. From the desert to the tropics to the arctic, the rugged 9E.03 heavy-duty gas turbine provides essential power and performs in a vast number of duty cycles and applications. The 9E.04 gas turbine provides increased power and performance while maintaining the simplicity and operational strengths of the 9E.03.

| 9E.03 | 9E.04 | |

|---|---|---|

| Net output (MW) | ||

| Net heat rate (kJ/kWh, LHV) | ||

| Net efficiency (%, LHV) | ||

| Net heat rate (Btu/kWh, LHV) |

9E series gas turbines can run on 52 types of fuel.

A single, economical solution for the dispatch needs of nearly every industry condition.

| LMS100 PA+ | LMS100 PB+ | |

|---|---|---|

| Net output (MW) | ||

| Net heat rate (kJ/kWh, LHV) | ||

| Net efficiency (%, LHV) | ||

| Net heat rate (Btu/kWh, LHV) |

LMS100 gas turbines can start up in 8 minutes

The 7E.03 gas turbine is recognized as an industry leader for 60 Hz industrial power applications. Its robust architecture and operational flexibility make it well-suited for a variety of peaking, cyclic, and baseload operations. With state-of-the-art fuel handling equipment, multi-fuel combustion system options, and advanced gas path features, the 7E gas turbine can accommodate a full range of fuel alternatives while helping to deliver better efficiency and lower emissions than other technologies in its class.

| 7E.03 | |

|---|---|

| Net output (MW) | |

| Net heat rate (kJ/kWh, LHV) | |

| Net efficiency (%, LHV) | |

| Net heat rate (Btu/kWh, LHV) |

7E series gas turbines can deliver 100% load in 10 minutes.

GE Vernova’s 6F gas turbine offers the superior performance, reliability, and flexibility typically associated with larger power plants. Our 6F gas turbine packs big power into a small package, offering durability and flexibility for harsh, remote, or floating power environments. Whether it be for 50 or 60 Hz, the 6F gas turbine can maintain enhanced output and exhaust energy for combined cycle and CHP performance. The 6F offers segment-leading 32,000-hour combustion and hot gas path inspection intervals.

| 6F | |

|---|---|

| Net output (MW) | |

| Net heat rate (kJ/kWh, LHV) | |

| Net efficiency (%, LHV) | |

| Net heat rate (Btu/kWh, LHV) |

6F gas turbines offer fuel flexibility and hydrogen capability while maintaining the reliability you’ve come to depend on

A leader in the +40 MW space, the LM6000 has over 40 million operating hours and more than 1,300 units shipped.

| LM6000 PG | LM6000 PF | LM6000 PF+ | LM6000 PC | |

|---|---|---|---|---|

| Net output (MW) | ||||

| Net heat rate (kJ/kWh, LHV) | ||||

| Net efficiency (%, LHV) | ||||

| Net heat rate (Btu/kWh, LHV) |

LM6000 gas turbines can start up in 5 minutes

Its ability to operate in island mode, coupled with multiple decades of proven rugged performance, make the 6B an excellent solution for remote installations and extreme operating conditions. The rugged, reliable 6B heavy-duty gas turbine is a popular choice for refineries, natural gas liquefaction power, CHP applications, and industrial power.

| 6B | |

|---|---|

| Net output (MW) | |

| Net heat rate (kJ/kWh, LHV) | |

| Net efficiency (%, LHV) | |

| Net heat rate (Btu/kWh, LHV) |

6B gas turbines can operate on a wide range of non-standard gas or liquid fuels, including over 90% hydrogen

The LM2500 family of aeroderivative gas turbines boasts several times the operating experience of its competitors combined, and its flexibility and reliability are unsurpassed.

| LM2500XPRESS +G4 DLE | LM2500XPRESS +G5 DLE | LM2500 +G4 DLE | LM2500 +G4 SAC | |

|---|---|---|---|---|

| Net output (MW) | ||||

| Net heat rate (kJ/kWh, LHV) | ||||

| Net efficiency (%, LHV) | ||||

| Net heat rate (Btu/kWh, LHV) |

LM2500 gas turbines feature >99.8% availability

Introducing one of the world’s most modular, reliable, and experienced mobile gas turbines.

| TM2500 | |

|---|---|

| Net output (MW) | |

| Net heat rate (kJ/kWh, LHV) | |

| Net efficiency (%, LHV) | |

| Net heat rate (Btu/kWh, LHV) |

TM2500 gas turbines can be installed and commissioned in 11 days

*Trademark of GE Vernova and/or its affiliates.

Gas Power

Gas Power engineers cleaner, more accessible energy that communities depend on to power growth and prosperity.

Contact usDecarbonization - the future of energy

See how Gas Power is helping to build a world that works.

Learn more