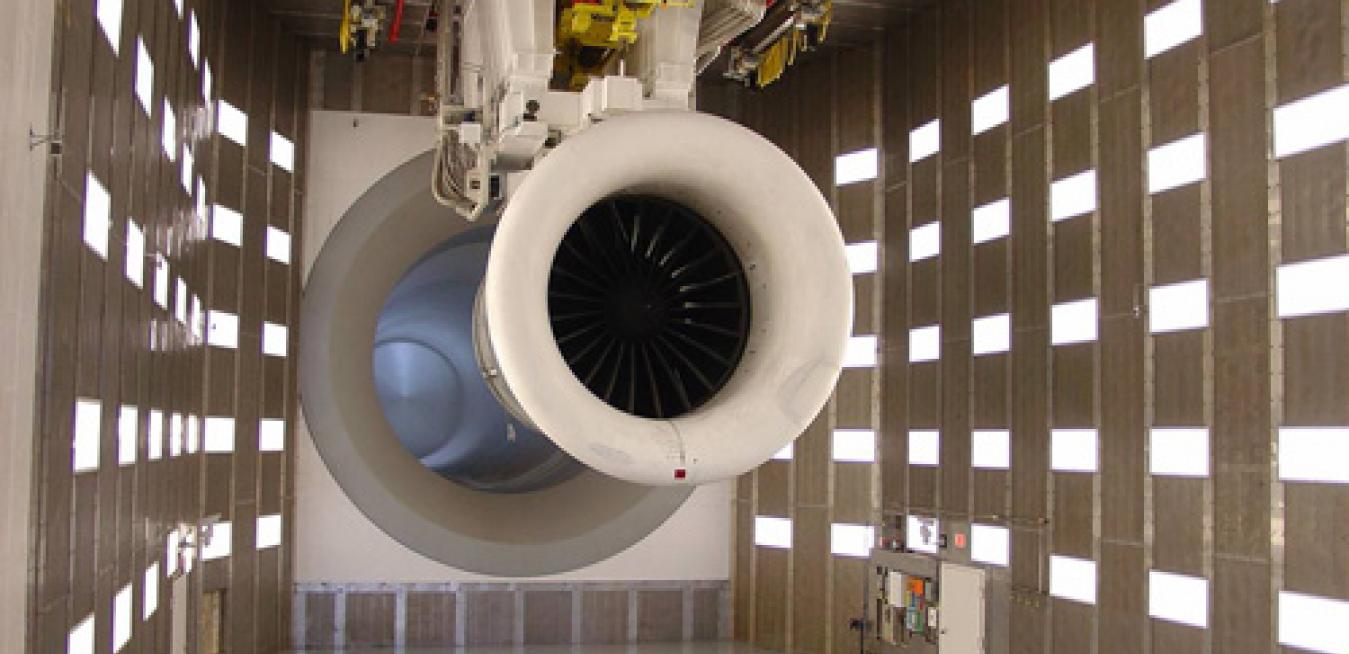

俄亥俄州EVENDALE,2013年12月20日------国泰航空公司订购了21架以GE9X发动机为动力的波音777-9X飞机,成为亚太区首家选择新型GE9X发动机的客户。GE9X发动机是极为成功的GE90系列发动机中的最新型号。

国泰航空还签署了为期十五年的OnPointSM服务协议,涵盖GE9X发动机的维护、修理及大修服务。

"国泰航空选择GE9X发动机表明他们对我们新的宽体发动机技术充满信心,"GE航空集团总裁兼首席执行官戴维. 乔伊斯(David Joyce)表示。"采用GE9X发动机的新型波音777X系列飞机将大幅提高性能和燃油效率。我们期待着携手波音公司,为客户设计出最好的宽体飞机。"

自从波音于3月份选择了GE9X发动机为其新的777X系列飞机提供动力以来,已有五家客户订购了550多台GE9X发动机:汉莎航空公司、阿提哈德航空公司、阿联酋航空公司、卡塔尔航空公司和国泰航空公司。按目录表价格计算,这些订单的总价值超过了210亿美元。