Overview

Overview of the Reliability Centered Maintenance (RCM) Module

Reliability Centered Maintenance (RCM) is a process to establish the safe minimum levels of maintenance while ensuring an equipment continues to perform to its design function within the current operating context. It achieves this by providing a means for determining optimal maintenance and operational strategies based on the probability and consequence of the analyzed failure modes.

The GE Digital APM RCM implementation utilizes the following seven basic questions that are outlined in SAE Standard JA1012, "Evaluation Criteria for Reliability-Centered Maintenance (RCM) Processes":

- Functions: What are the functions and desired performance of the (asset or system) in its present operating context?

- Functional Failures: In what ways can it fail to fulfill its functions?

- Failure Mode: What causes each functional failure?

- Failure Effect: What happens when each failure occurs?

- Failure Consequences: In what way does each failure matter?

- Recommended Actions: What should be done to predict or prevent each failure?

- Default Actions: What should be done if a suitable RCM task cannot be found?

Access the RCM Overview Page

About This Task

Procedure

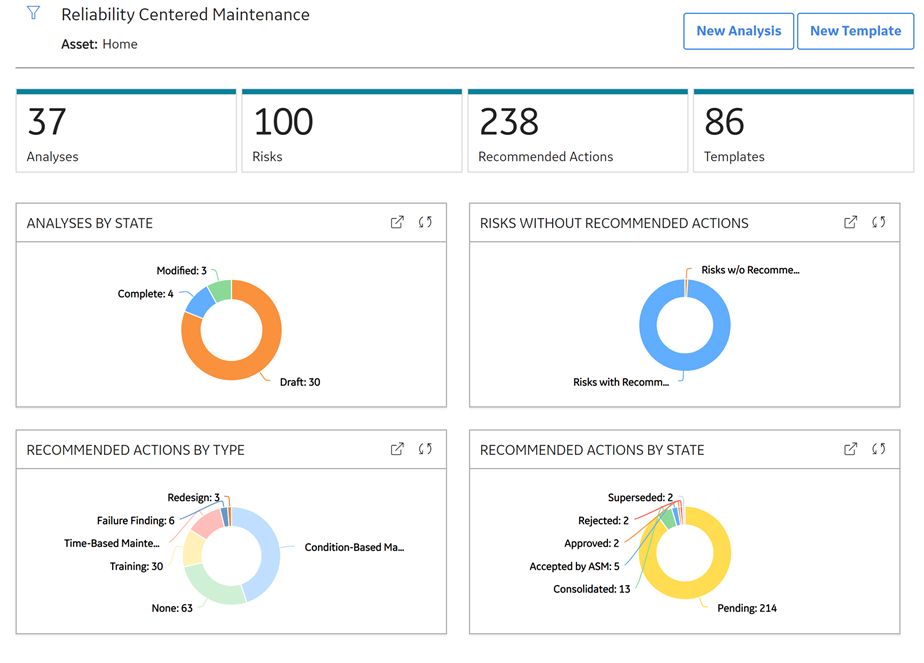

The RCM Overview page appears, displaying the following tabs:

- Analyses:: All analyses in the module.

- Risks: All the failure modes and effects associated with the analyses in the module.

- Recommended Actions: All the recommendations associated with the analyses in the module.

- Templates: All templates in the module.

The page contains the following charts:

- Analyses by State: Plots the number of analyses in each state.

- Risks Without Recommended Actions: Plots the number of failure effects in analyses with and without associated recommended actions.

- Recommended Actions by Type: Plots the number of recommended actions of each type in all the analyses.

- Recommended Actions by State: Plots the number of recommended actions in each state in all the analyses.

You can select

in the page to filter the information displayed on the Reliability Centered Maintenance Overview page to a specific time range or asset. When you filter by an asset, the page displays information for the selected asset and the assets under it in the hierarchy. The Home level includes information not related to an asset or related to an asset not in the Asset Hierarchy.

in the page to filter the information displayed on the Reliability Centered Maintenance Overview page to a specific time range or asset. When you filter by an asset, the page displays information for the selected asset and the assets under it in the hierarchy. The Home level includes information not related to an asset or related to an asset not in the Asset Hierarchy.

Reliability Centered Maintenance (RCM) Analysis Workflow

This workflow provides the basic, high-level steps for using this module. The steps and links in this workflow do not necessarily reference every possible procedure.

- Create the RCM Analysis record.

- Create the Analysis team.

- Define the equipment and location list, which helps define the RCM system. Note that each RCM FMEA Asset record can optionally be linked to an Equipment or Functional Location record.

- Define the functions of the system.

- Define functional failures for each system function.

- Define failure modes for each Functional Failure.

- Define the failure effects for each Failure Mode.

- Define Recommended Actions for each Failure Effect.

GE Digital APM provides various tools that you can use to accomplish these tasks. The tools that you use will depend on your personal preference.