Search GE Gas Power

What are you looking for?

Or start with a popular search:

Recommended resources

Evaporative cooler upgrade

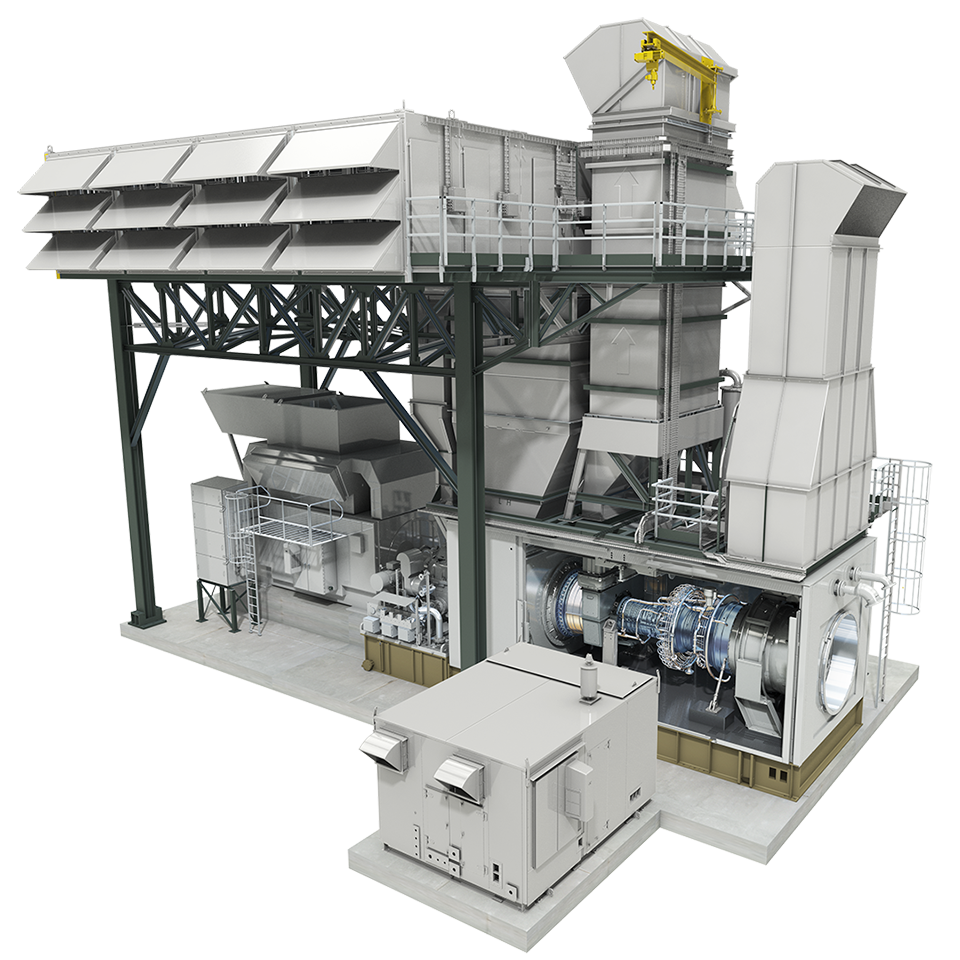

GE’s evaporative cooling system provides a power output and efficiency increase for sites with high ambient temperatures and low relative humidity.

Benefits

How does it work?

The system will cool compressor intake air through humidification, raising relative humidity and lowering the inlet temperature. Inlet air cooling increases the air mass flow rate and compressor functionality, resulting in higher turbine output power and efficiency.

The system:

- Evaporative cooling unit bolted to the incoming air face of the filter house.

- A single bank of evaporative cooling media made of corrugated layers of fibrous material, allowing minimal air pressure loss. Water flows down the channels by gravity. The media consists of two modules.

- The bottom module features a sump containing the pump and fill valves.

- The upper module has a drain pan and piping to cycle water back to the sump.

- A drift eliminator to limit water entering the turbine.

More information

- Significantly increases turbine power output.

- Increases thermal engine efficiency.

- PLC integrated controls sample weather conditions every 30 seconds, allowing rapid adaptability to changing conditions.

- PLC integrated controls system allows evaporative cooling system to work as a standalone unit, limiting control integration complexity. Only alarm systems need to be integrated.

- Adaptable to extrinsic control systems.

- Some units may have the evaporative cooler pre-installed while others will require the filter house to be opened.

- To control the inlet chilling system, GE will provide a modular hardware style PLC.

Gas Power

Gas Power engineers cleaner, more accessible energy that communities depend on to power growth and prosperity.

Contact usDecarbonization - the future of energy

See how Gas Power is helping to build a world that works.

Learn more

© 2024 GE Vernova and/or its affiliates. All rights reserved.