Boeing’s 737 passenger jet became the world’s best-selling aircraft last Wednesday, when the plane builder delivered the 8,000th jet to United Airlines.

United was the first airline to order and take delivery of the second generation of the plane, the 737-200, in 1968. It has since received more than 550 737 aircraft.

In December 2011, a Boeing 787 Dreamliner powered by two GEnx jet engines set a pair of world records for the fastest eastbound trip around the world and longest flight for an aircraft in its class.

The words jet engine testing call to mind the heady days of Chuck Yeager pulling Mach 2.44 over the California desert. These days, the testing tends more toward the high-tech than cowboy, but it’s no less awesome a site to behold. That’s why GE recently loosed a gaggle of Instagram photographers on GE Aviation’s Peebles Test Operation in Ohio to document the space age facilities. We called it the first ever #GEInstaWalk.

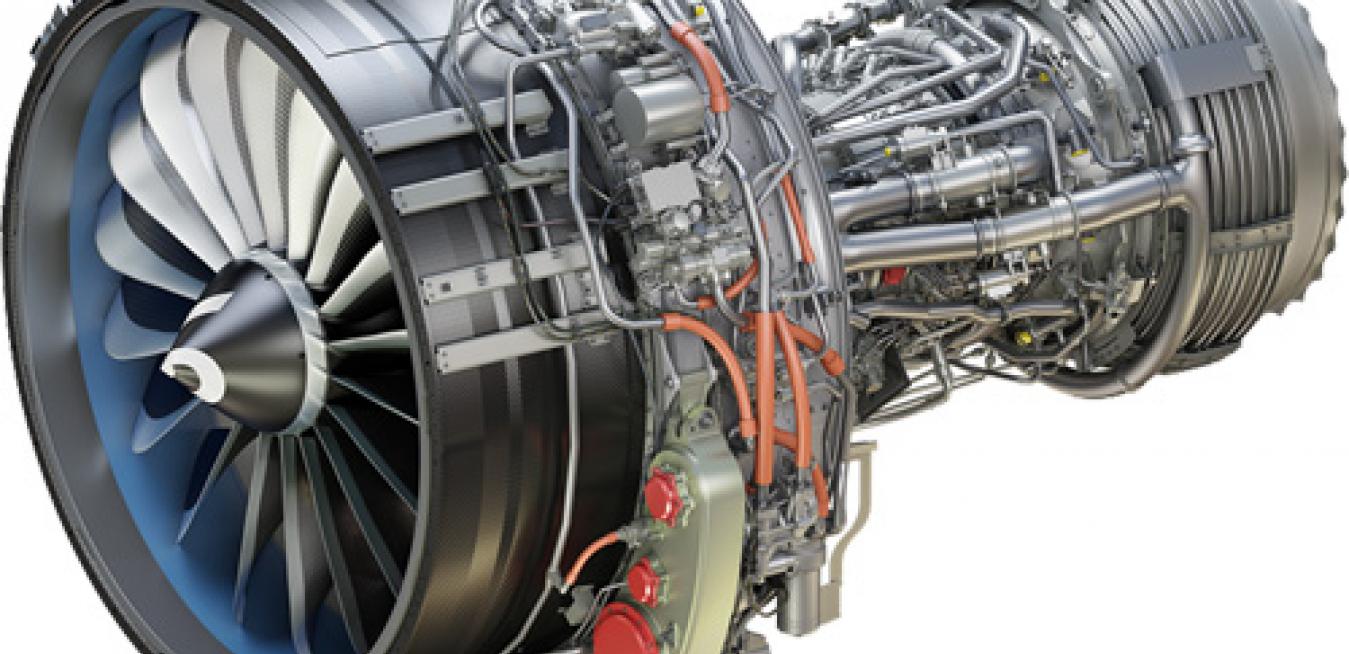

People have been using ceramics to store food, drink tea, and tile their homes for millennia. But GE engineers recently upped the ante and started putting high-grade ceramics inside jet engines.

Jet engine maker CFM International, a joint venture between GE Aviation and France’s Snecma, completed a design freeze for its latest jet engine that includes for the first time components made from advanced ceramic composites and parts manufactured using 3-D printers. “All of our testing and design work leading to this moment demonstrates that we are on track to meet all of our program commitments,” said Gareth Richards, LEAP program manager at GE Aviation.

Plane makers don’t mince words about the fastest growing market in aviation. “Single-aisle aircraft remain pivotal,” declares Boeing’s long-term market view. “Over the next 20 years, we project that 23,240 single-aisle planes will be delivered, representing nearly 70 percent of commercial plane deliveries and 45 percent of total delivery value,” Boeing says.