The Middle East is quickly becoming a new global aviation hub with big plans for the future. Nowhere are those plans better visible than at giant airshows like the one in Farnborough, UK, which finished this week. Emirates and Qatar Airlines, for example, finalized multi-billion orders for Boeing’s next-generation 777X long-haul planes, building on a momentum from last year’s Dubai airshow.

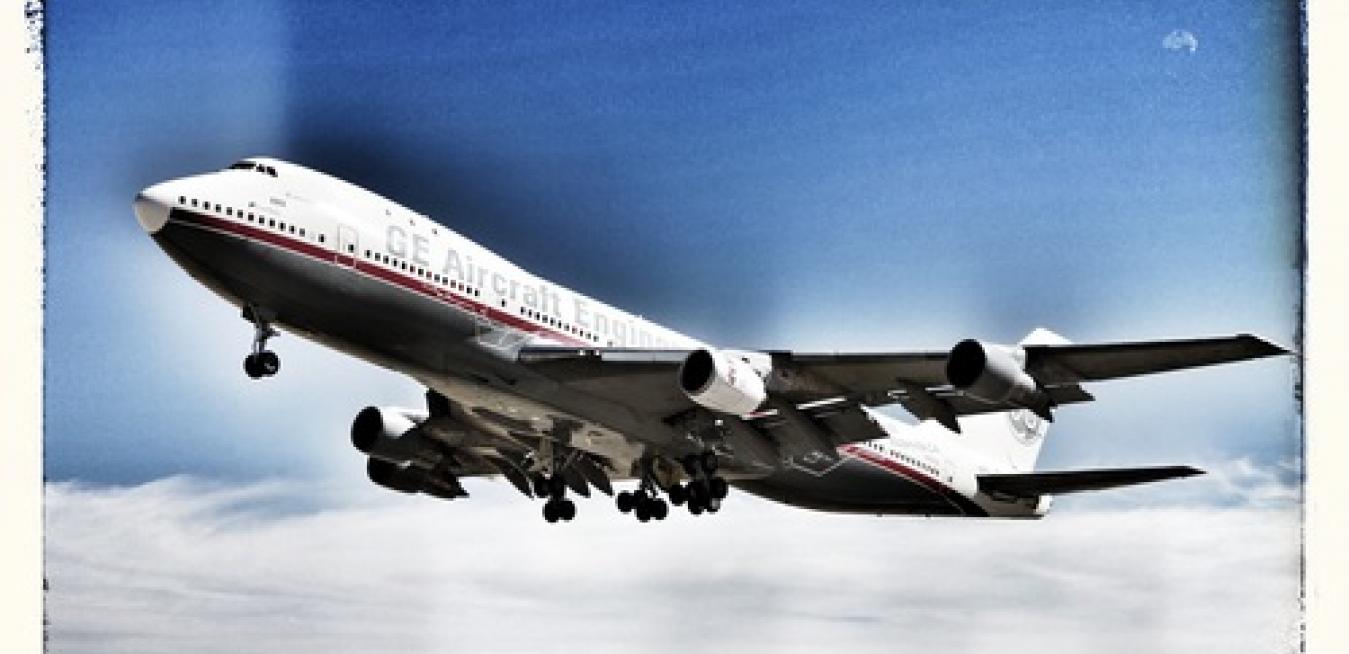

When GE engineers wanted to make their jet engines more efficient, they developed a special ceramic material that can operate at temperatures where most metal alloys grow soft. But the idea of putting ceramics inside jet engines was so revolutionary that they took the material to a shooting range and blasted it with steel balls flying at 150 mph to prove that it was viable (see image below).