Every day, the world’s power grids are adapting to bridge the gap between the fossil fuel era and the renewables age. Instrumental in building that bridge are the 700 operators and managers who work at GE’s Grid Solutions Advanced Manufacturing Facility in Clearwater, Florida, and produce thousands of components such as capacitors and power sensors, which help the grid absorb wind and solar generation smoothly and safely.

Any GE Aerospace employee who has spent the day at Avio Aero’s plant in Pomigliano d’Arco, Italy, would probably agree that two aspects of the workplace are unimprovable: the view and the food. The GE-owned plant in northeast Naples, which manufactures blades, combustors, and other components for some of the world’s largest jet engines, looks out on Mount Vesuvius, the volcano that buried Pompeii in ash two millennia ago.

The difference is, or should be, palpable. The good, the bad, and sometimes the ugly. For teams who truly practice lean and believe in it, those latter two descriptors are nothing but opportunity.

Categories

tags

Dan Morey had a problem. He knew the vast compressed air system in Building 273 was leaking air, but he didn’t know where.

One afternoon in July at the Oshkosh airshow in Wisconsin, Brad Mottier made his way through the crowded exhibition grounds to see BlackFly, an ovoid, all-electric one-seater that can take off vertically and zip across the sky like an insect at 60 miles per hour. He spent the next 20 minutes talking to the builders while studying the propulsion, construction, design and other features of the alien-looking craft.

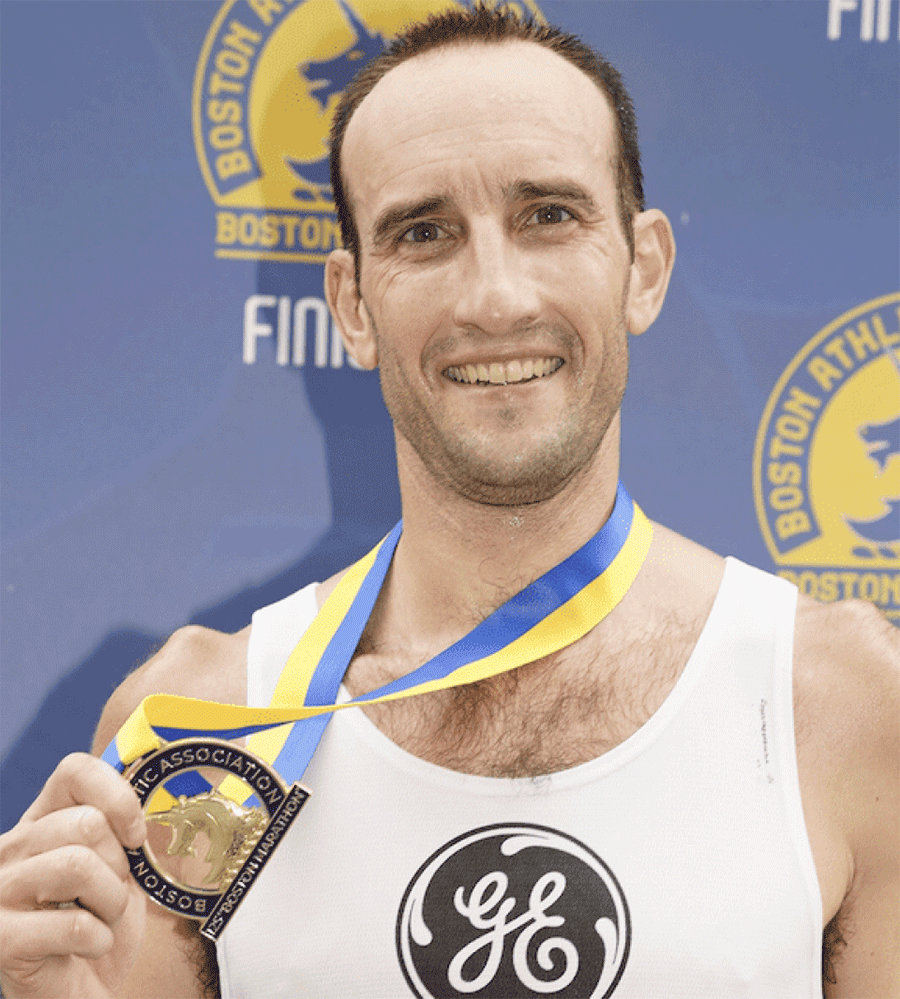

Engineer and avid runner David Riddle usually finds himself asking “Why do I do this” during races. But this year’s 125th running of the Boston Marathon was an exception.

That’s not to say that it wasn’t hard or that it didn’t hurt. It did. But everything was going according to plan. A rarity in distance running. While Riddle has run upwards of 10 marathons, many more 50K+ races and even two 100-plus-mile races, this was his first Boston Marathon.

In the 1970s, a team of researchers from the Massachusetts Institute of Technology traveled to Japan to figure out why that country’s automakers were delivering cars faster than their competitors in Detroit. Their search led them to Toyota and its Toyota Production System — a set of management principles focused on boosting safety, quality and efficiency, reducing waste and creating more value with fewer resources.

Back in 2017, GE engineers surprised the world when they took what was then the world’s most powerful jet engine and used its technology to turn it into a power plant that could be capable of generating enough electricity for thousands of households. This feat got plenty of attention, but the team was not finished. A new GE team has now turned the machine into yet another example of the power of innovation.

2020 marked the 75th anniversary of the end of World War II, the 50th year in which Earth Day was celebrated, a quarter-century since the release of the kids’ movie “Toy Story” and — for good measure — the 2,500th anniversary of the Battle of Thermopylae. GE marked a few significant milestones as well; none featured Buzz Lightyear, but they did involve some pretty cool aviation technology.

GE has placed lean management at the heart of its strategy for success.