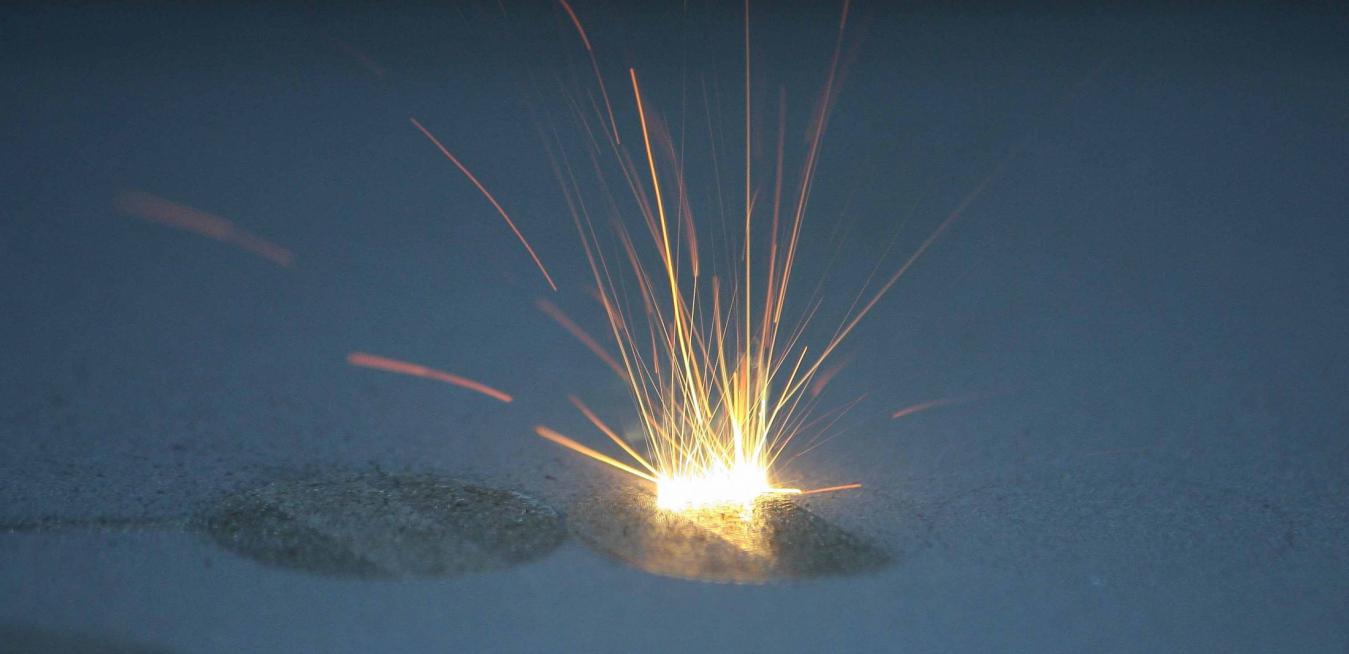

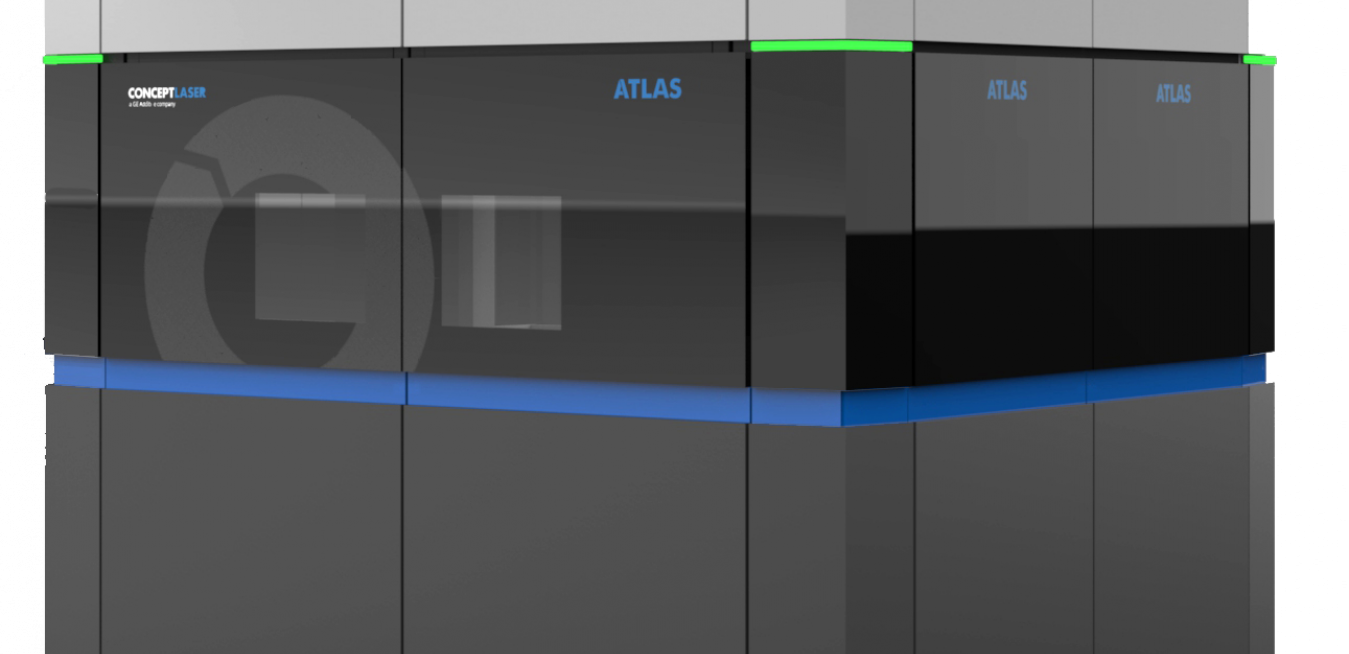

Back in 2015, Hart was trying to print a special metal probe from a cobalt-chrome alloy at GE Power’s Advanced Manufacturing Works in Greenville, South Carolina. 3D printers build parts, step by tiny step, by fusing together superthin layers of fine metal powder with a laser or other powerful energy source.

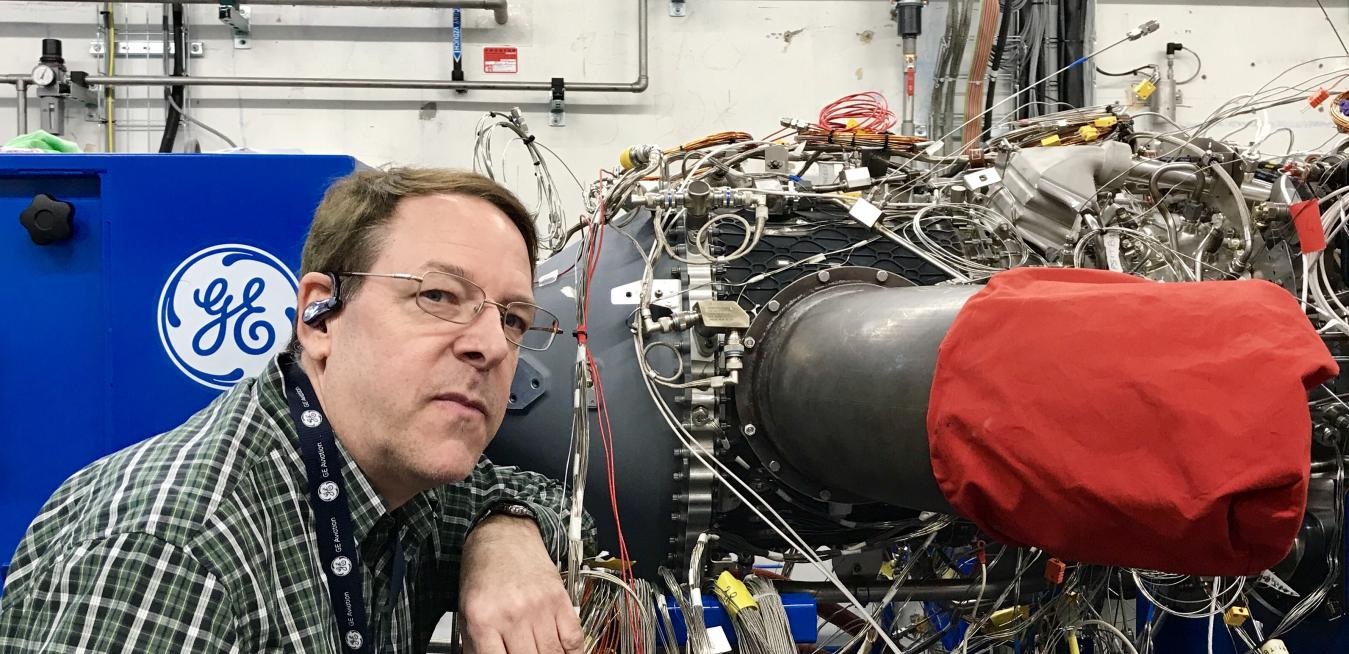

Jet engines are large and complicated machines. But sometimes surprisingly small parts can make a big difference in how they work.

A decade ago, engineers at CFM International, a joint venture between GE Aviation and France’s Safran Aircraft Engines, started designing a new, fuel-efficient jet engine for single-aisle passenger planes — the aircraft industry’s biggest market and one of its most lucrative.