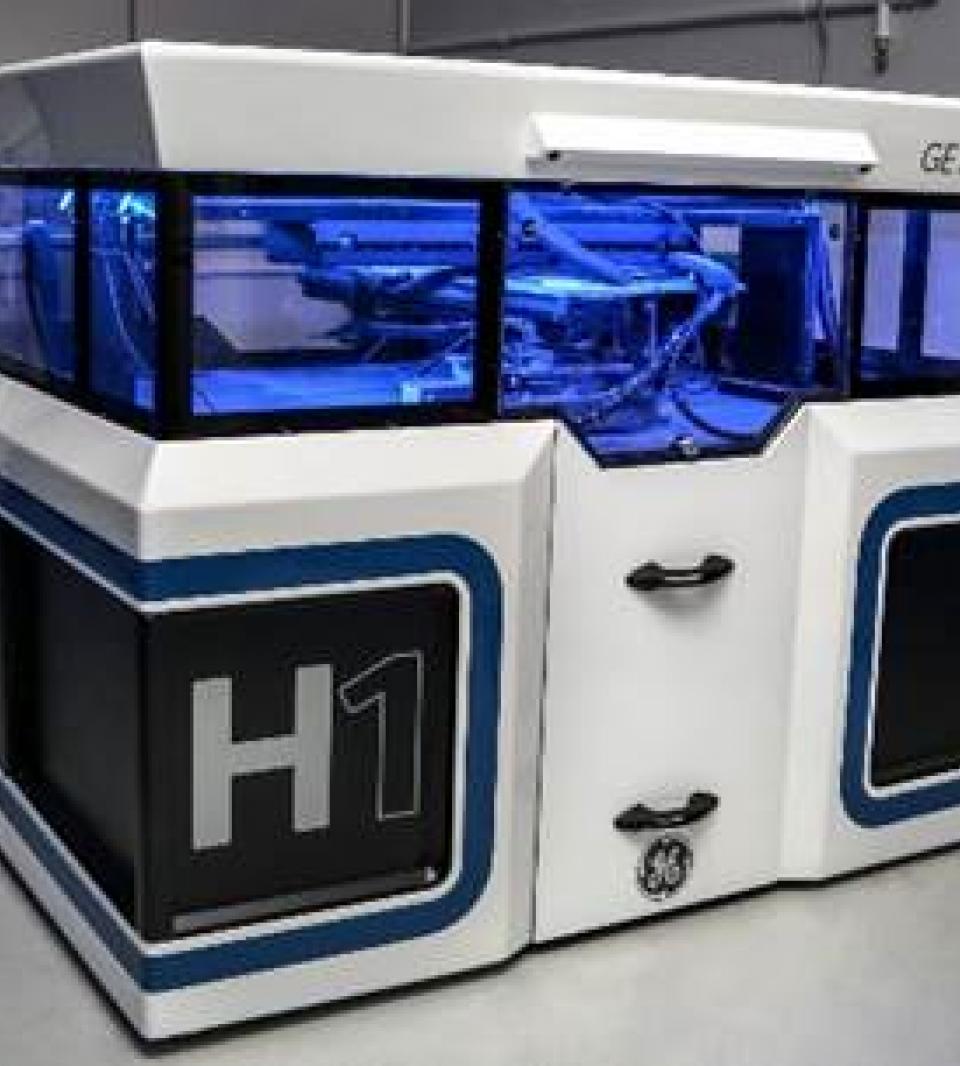

Just a decade ago, the idea of 3D printing metal parts directly from a computer file seemed like science fiction to many people. But the technology is quickly growing up. There are few better examples of its promise than the GE Catalyst, a new advanced turboprop engine GE Aviation started testing in December.

The Northern Italian town of Cameri could be easily mistaken for a quiet farming commune. But take a short ride through the rolling fields of the fertile Po Valley that surround it and you’ll discover a startling contrast.

Seeing Around Corners

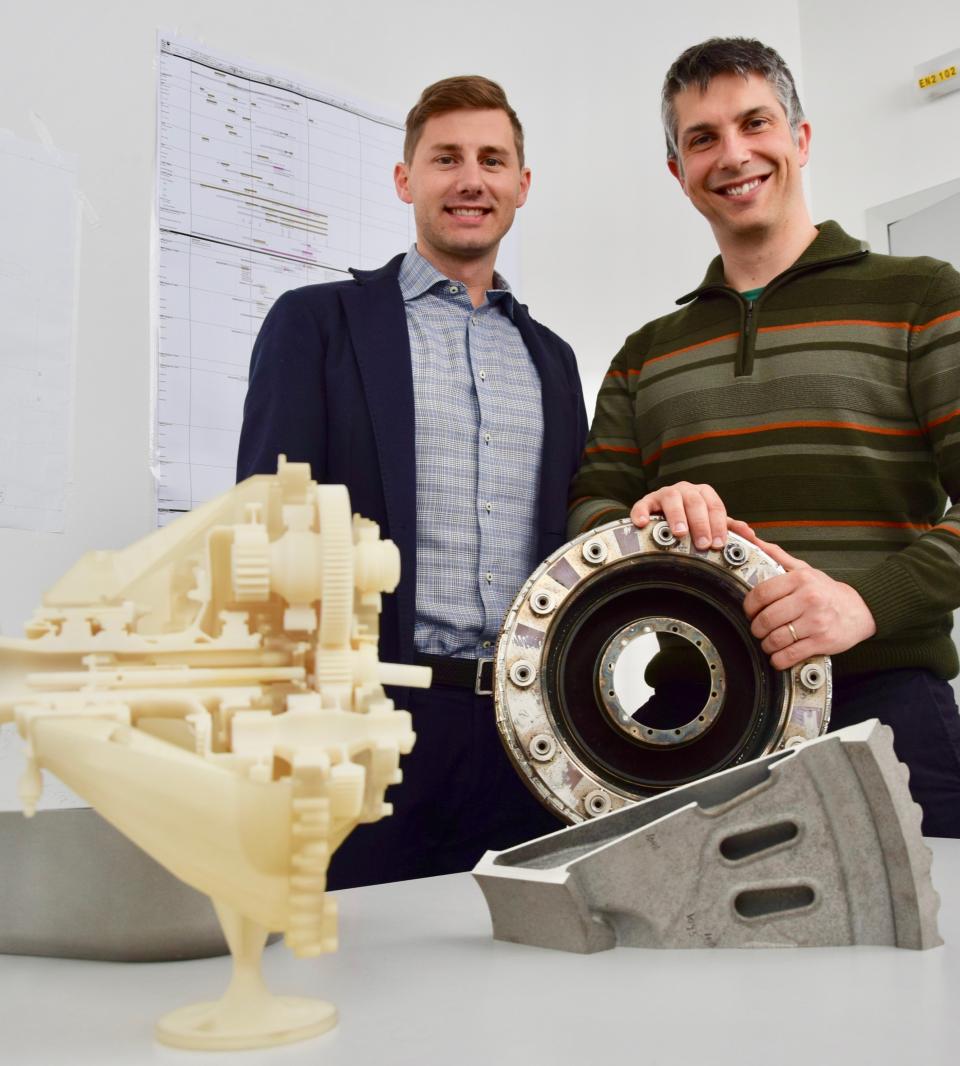

GE engineers recently built and tested 30 different prototypes of a complex, football-size jet engine component. Thanks to cutting-edge 3D-printing technology, they were able to reach the perfect design in just 12 weeks. This is remarkable considering it would take several years to iterate on that many designs using traditional casting methods.