- Awarded four-year, $14.3 million project through the Defense Advanced Research Projects Agency’s (DARPA) Atmospheric Water Extraction (AWE) program

- Device would provide troops in the battlefield with ready source of potable water, while significantly reducing the cost and logistics of transporting water

- Solution could be a future gamechanger in addressing water scarcity

business unit

tags

GE has been 3D printing parts for jet engines and gas turbines. In the recent years, the technology also entered another field: wind power. GE Renewable Energy, together with leading research centers, national labs and key industrial partners, has been testing such new manufacturing technologies and materials on large components like wind turbine towers 3D-printed from concrete — and more recently, blades.

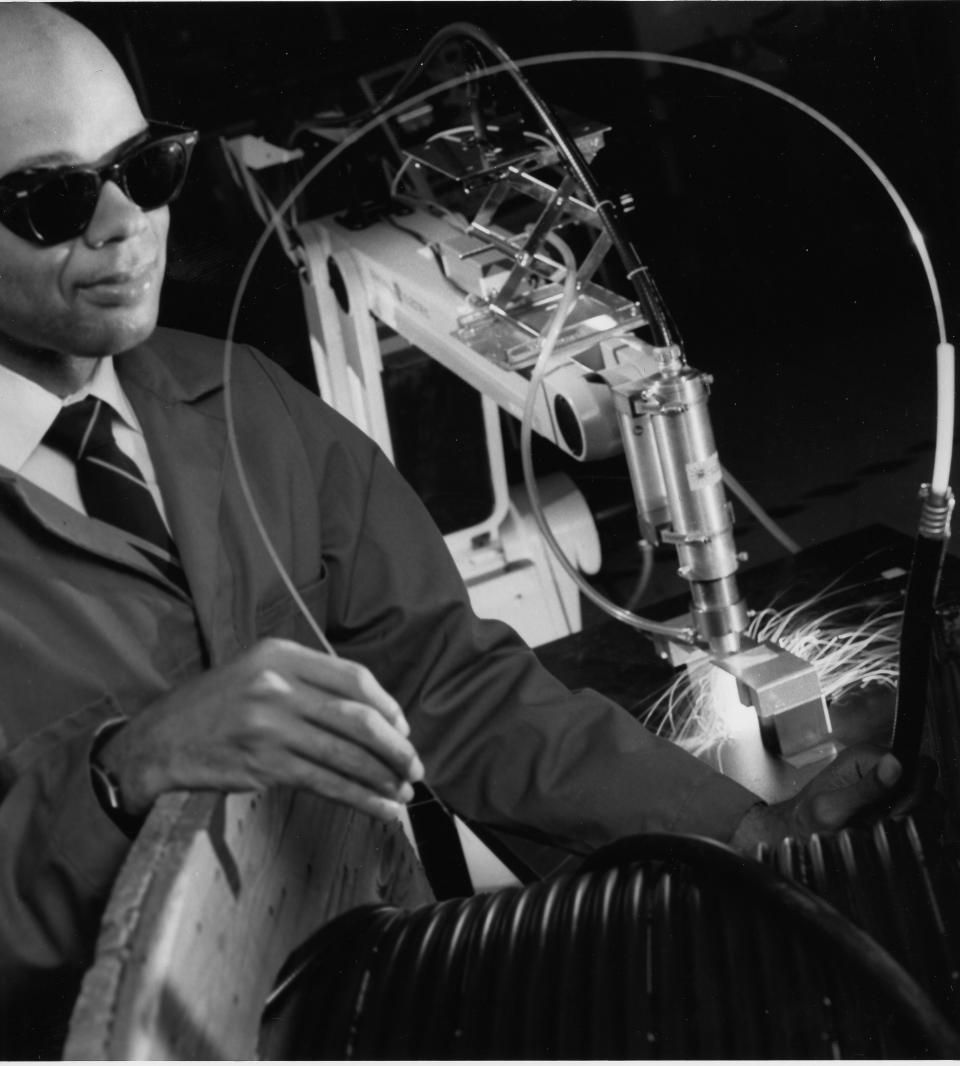

Marshall Jones knows a thing or two about beating the odds, but it’s not just because of his knack for mathematics. A model of perseverance, the laser pioneer was raised by his extended family on a duck farm but ended up laying the foundation for additive manufacturing, a new breed of technologies that allow companies to 3D-print things from metal.

In the relatively short time that it’s been around, 3D printing, also known as additive manufacturing, has upended the idea of what engineers can design and produce. Sure, past designers could come up with all kinds of outlandish-looking concepts that could make machines more efficient. But their drawings would often elicit the same response from colleagues tasked with bringing their vision to life: But can you actually make it?

Big things often come from humble beginnings. Take the GE90, a jet engine so powerful it started a decades-long revolution in passenger aviation that is still ongoing.

The engine allowed large widebody jets with just two engines, instead of the typical four, to fly people between continents, lowering the cost of fuel and maintenance for airlines along the way. That, in turn, started a trend that ultimately spelled the end of service for the iconic Queen of the Sky — the Boeing 747 — and even the Airbus A380 double-decker.

It’s not easy to disrupt a $12 trillion industry – but 3D printing is doing just that. Manufacturing worldwide is embracing new technologies to print everything from artificial skin for cosmetics testing to woodworking tools. While a lot of 3D printing is still in the novelty stage, the airline industry has jumped early on the ability to construct lighter and stronger parts.

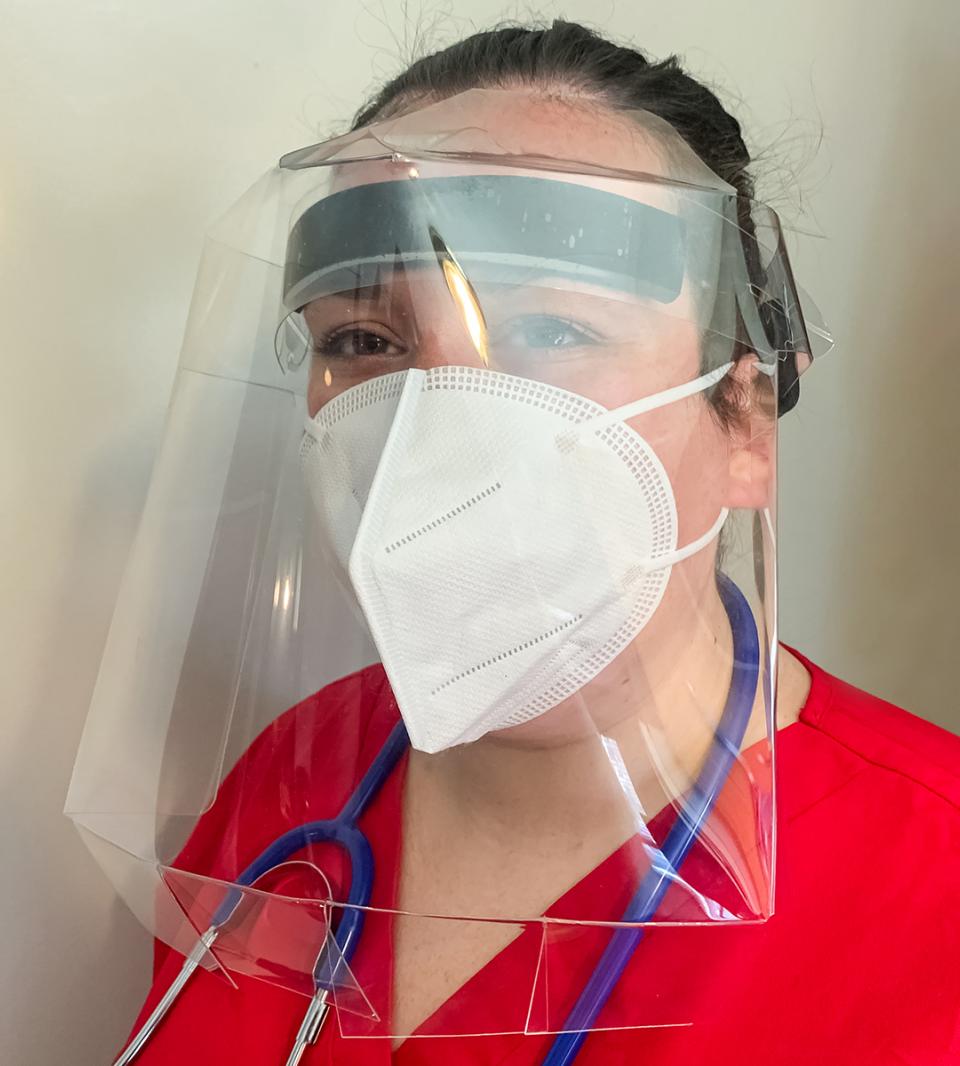

In early March, Kathy Armijo Etre was managing community outreach as vice president of mission for New Mexico’s oldest hospital, the Christus St. Vincent Regional Medical Center in Santa Fe. The hospital serves as the northcentral New Mexico hub hospital and is assisting with the statewide response to the COVID-19 outbreak amongst Native American populations. In her regular role, Etre set up programs to serve the area’s homeless and care for other vulnerable patients.

In the wild, a meerkat like 5-year-old Mark would spend much of his day foraging with his family group, snacking on anything from insects to reptiles to small mammals. But as a resident of the Cincinnati Zoo & Botanical Garden, the small, burrowing mammal receives his meals at predictable times from the zoo’s animal care staff. It’s safe and reliable, but often lacking the thrill of the chase.

Ever since he was a young bicycle racer in Greece in the 1980s, Dimitris Katsanis has been tinkering with ways to make bikes go faster. Now a celebrated bike designer, Katsanis became an icon in Britain when the bikes he created for its Olympic track cycling team helped win a slew of medals in Beijing in 2008 and London in 2012.

In the 1980s, when the U.S. Air Force opened up what is now known as the Great Engine War for propulsion systems to power its F-16 and F-15 fleets, GE saw its chance to again become a major supplier of power plants for fighter aircraft. Its engineers had developed the engine for the B-1 supersonic bomber, and they used its powerful and efficient beating heart — called the core — to design a new jet engine, the F110. The move was a resounding success.