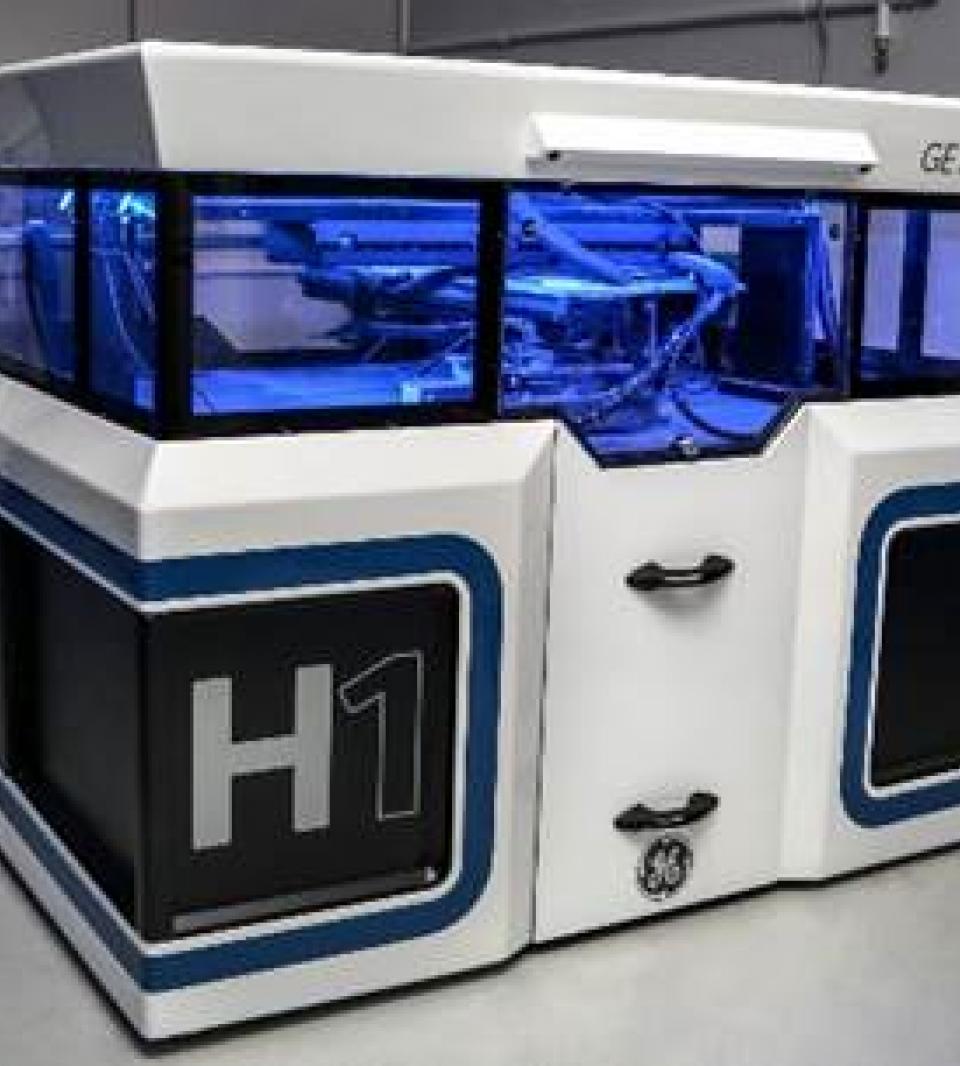

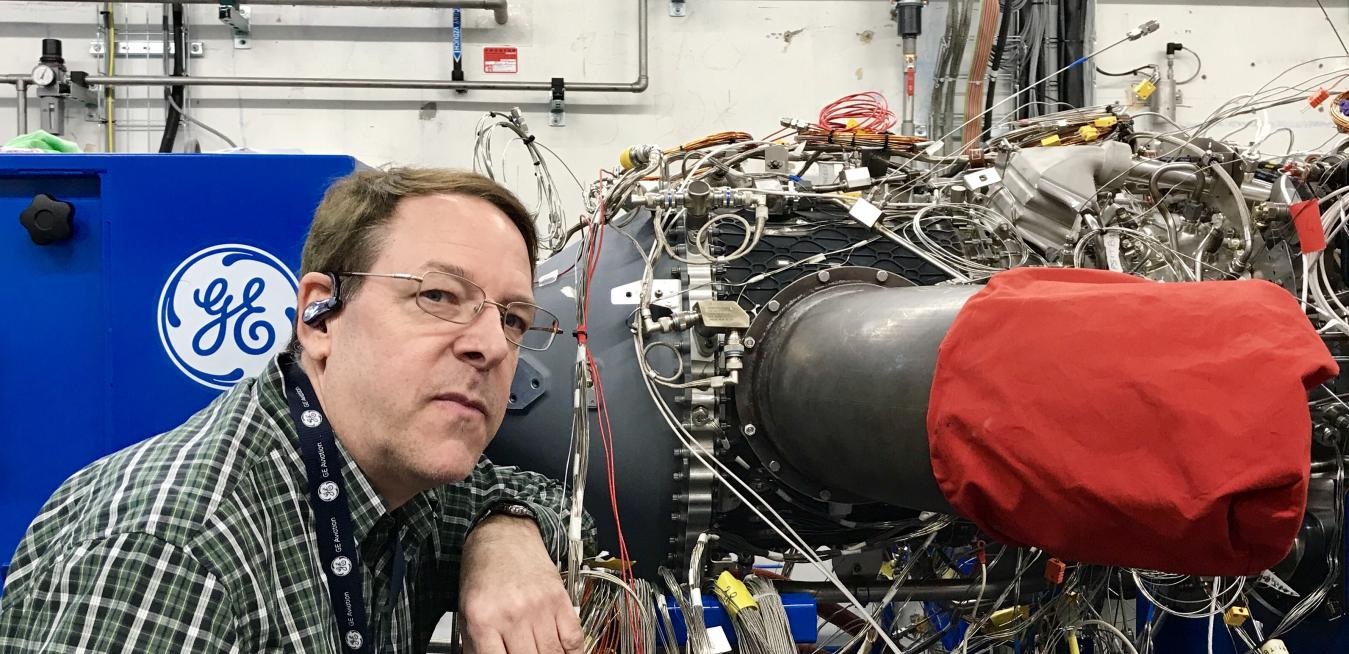

GE engineers recently built and tested 30 different prototypes of a complex, football-size jet engine component. Thanks to cutting-edge 3D-printing technology, they were able to reach the perfect design in just 12 weeks. This is remarkable considering it would take several years to iterate on that many designs using traditional casting methods.

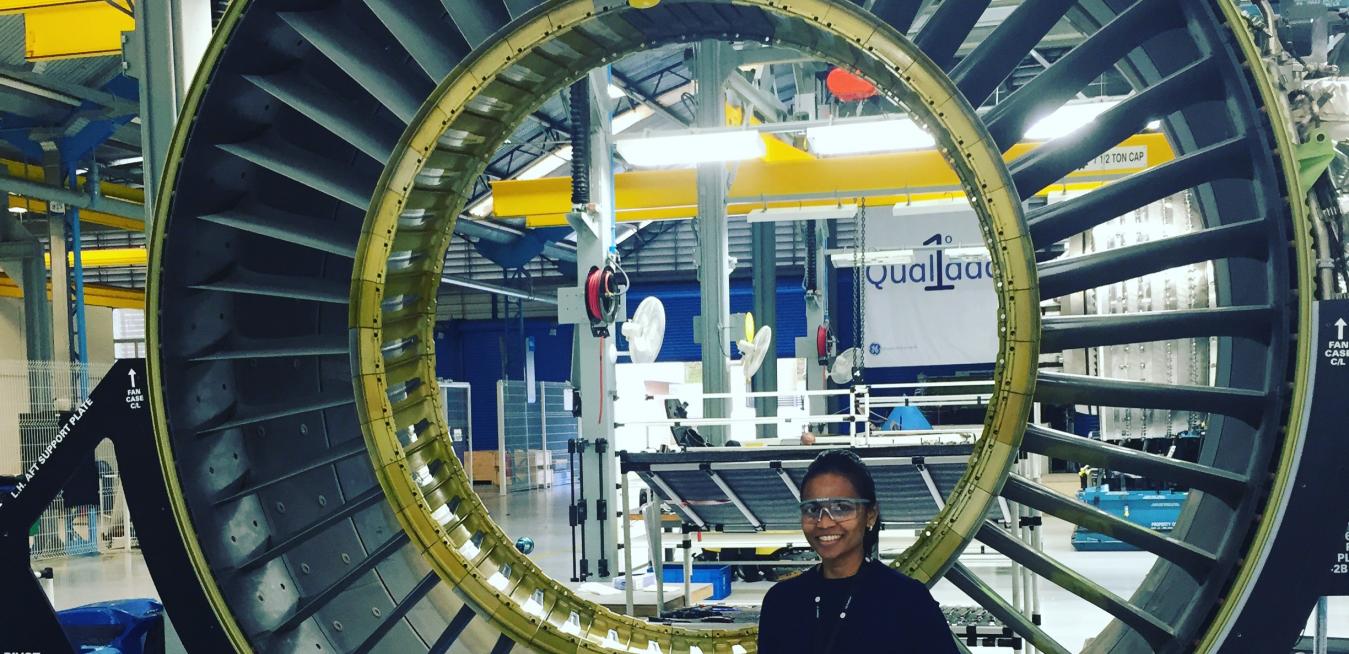

Jet engines are large and complicated machines. But sometimes surprisingly small parts can make a big difference in how they work.

A decade ago, engineers at CFM International, a joint venture between GE Aviation and France’s Safran Aircraft Engines, started designing a new, fuel-efficient jet engine for single-aisle passenger planes — the aircraft industry’s biggest market and one of its most lucrative.

Big data reveals insights to drive the Industrial Internet, but small data has impressive powers of persuasion, too.