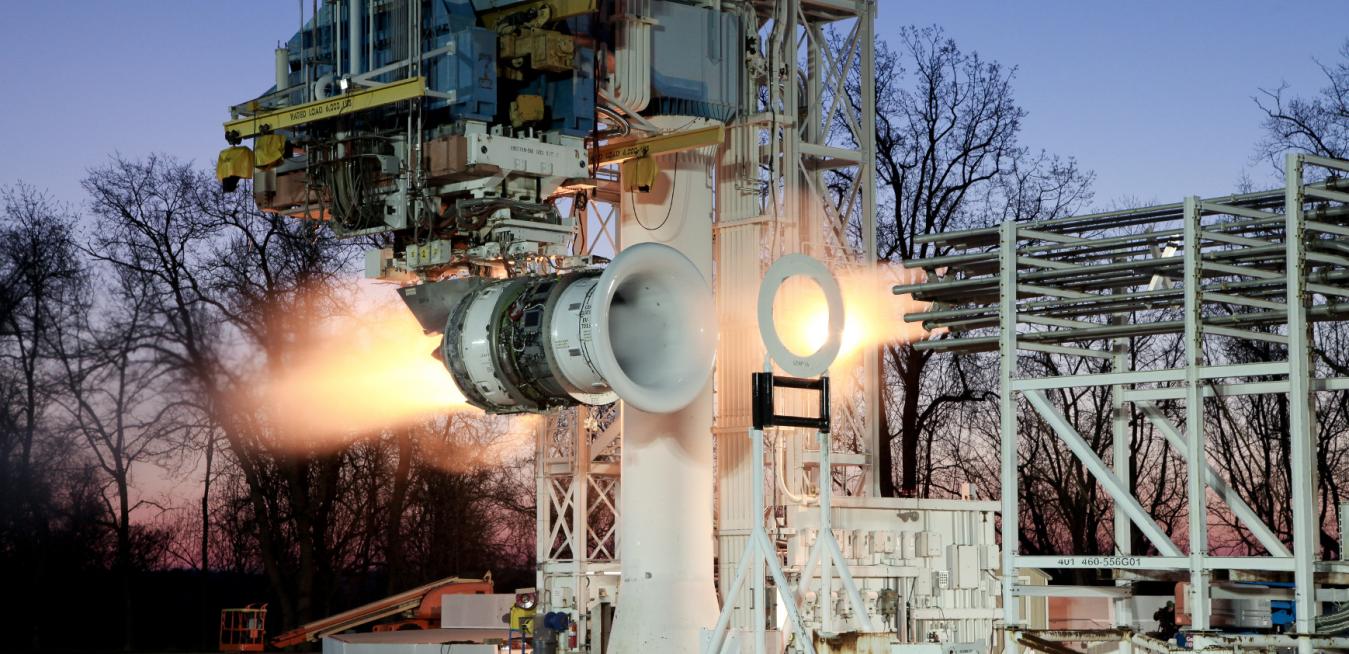

- Subscale Demonstration hits key milestone on the Lab’s project with ARPA-E called UPHEAT – Ultra Performance Heat Exchanger enabled by Additive Technology

- GE scientists using the power of 3D design and printing to break efficiency barriers and reduce carbon emissions in large-scale power generation and flight.

- Project on track for demonstration of heat exchanger prototype by Q1 2022 that operates at temperatures exceeding 1,650 °F and pressures >3,600 psi

NISKAYUNA, NY – June 23, 2021

For media inquiries, please contact:

Todd AlhartDirector, Innovation Communications

GE Aerospace

+1 518 338 5880

[email protected]