Jet engines are large and complicated machines. But sometimes surprisingly small parts can make a big difference in how they work.

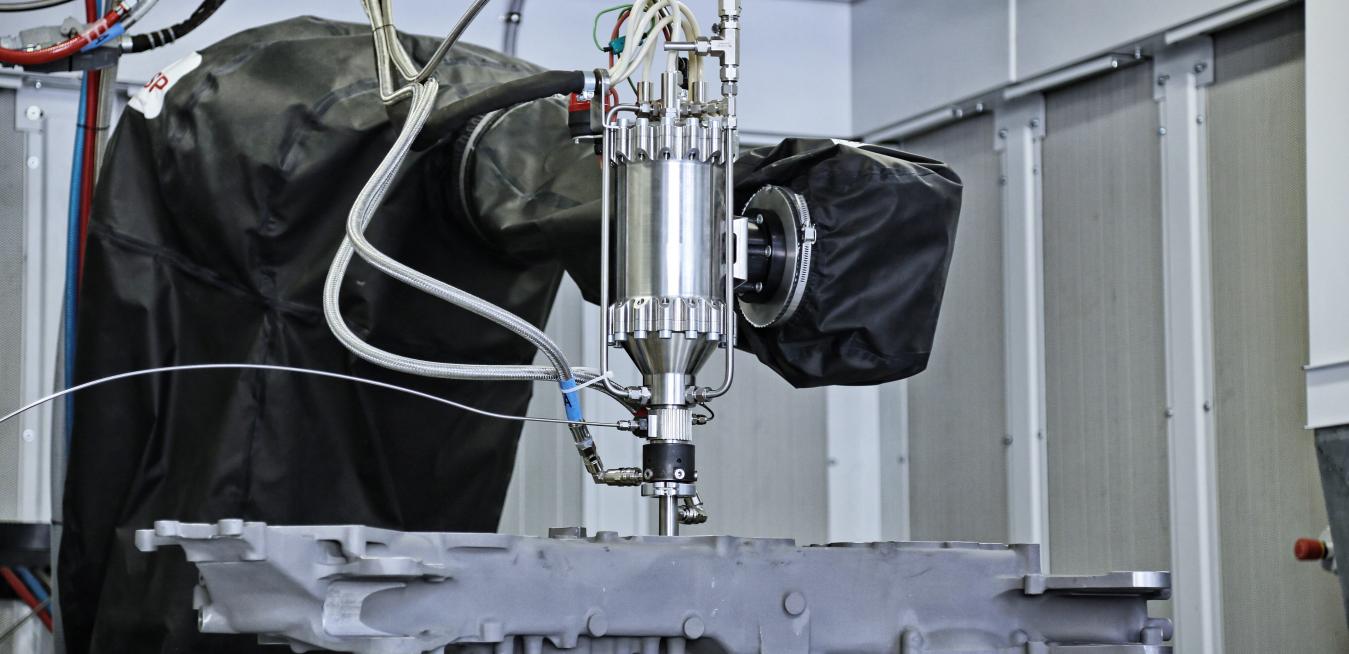

A decade ago, engineers at CFM International, a joint venture between GE Aviation and France’s Safran Aircraft Engines, started designing a new, fuel-efficient jet engine for single-aisle passenger planes — the aircraft industry’s biggest market and one of its most lucrative.

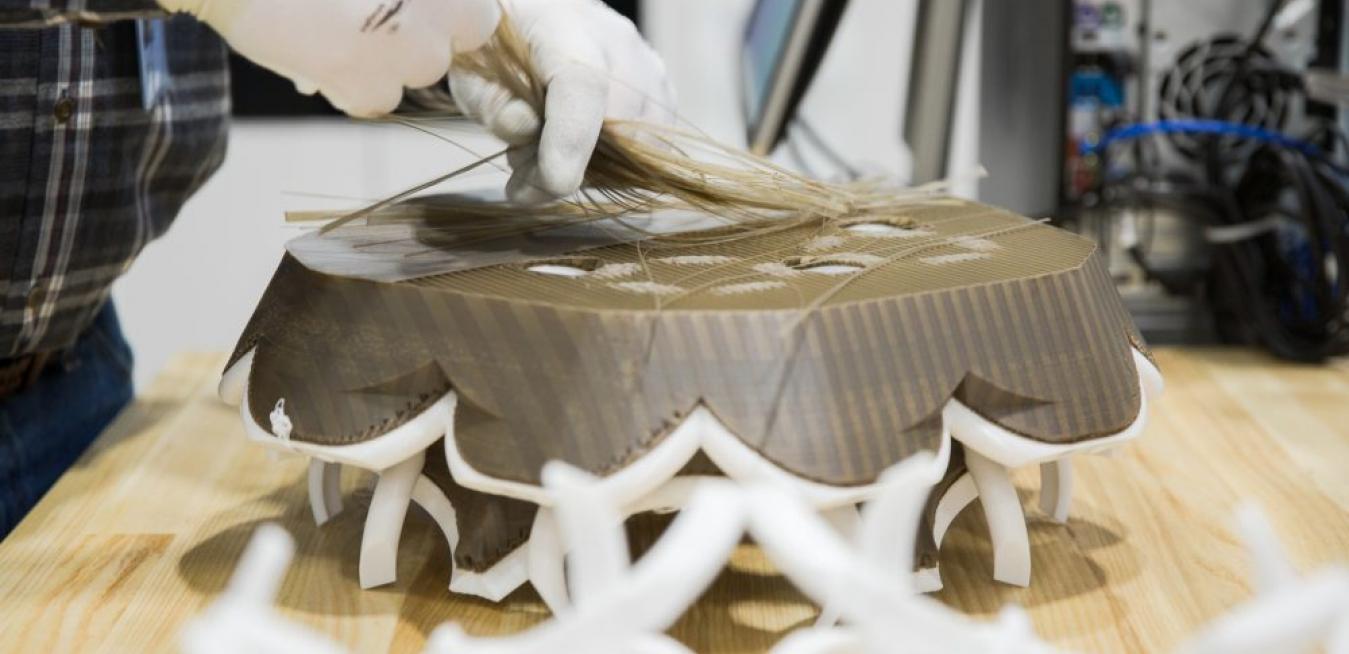

After 20 years of iteration on the same basic additive-manufacturing technologies for metal, a new wave of innovation is emerging. Lower-cost, safer processes are replacing the old ways of doing things, offering vastly different material properties through resolution, surface quality and design freedom.

Cyborg Dragonfly Takes Flight

[embed width="800"]https://vimeo.com/219709402[/embed]

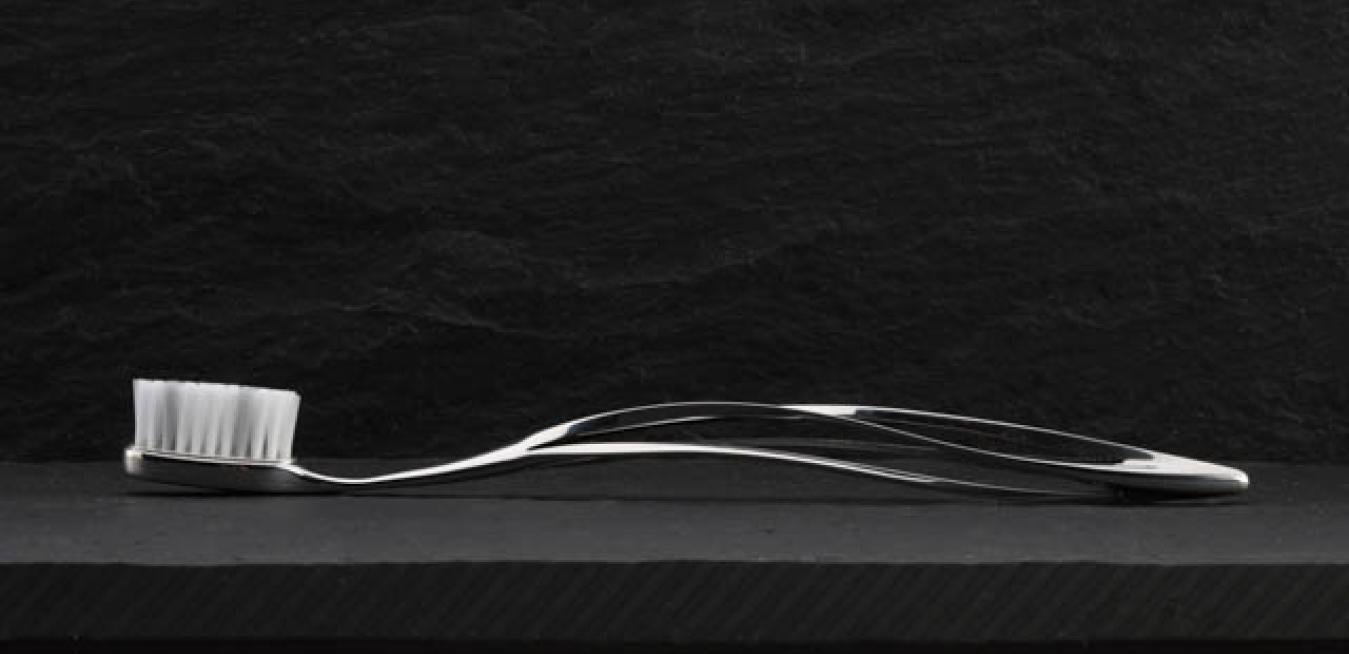

From hearing aids to jet engines, 3D printing is revolutionizing the world of manufacturing. How will commerce change when thousands of products, from cell phones to blenders, are customizable? Even though 3D printing is a 30-year-old technology, we’re just scratching the surface of where additive manufacturing will take us, writes Alan Amling, vice president of corporate strategy for UPS.

Of all the ways 3D printing will change the world, the democratization of manufacturing is perhaps the most important.