Astronauts Thomas Stafford, Eugene Cernan and John Young took their spacecraft, nicknamed Charlie Brown, to the lunar orbit. Stafford and Cernan then climbed inside the lunar module, dubbed Snoopy, and piloted it just 9 miles above the moon’s surface - after traveling some 240,000 miles from home.

Neil Armstrong and Buzz Aldrin closed the gap two months later and became the first humans on the moon.

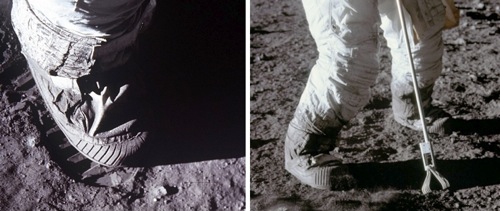

The Apollo program ran until 1972 and took 12 people to the surface of the moon and back. It also involved 6,000 GE workers and engineers who ground-tested the missions’s command and lunar modules, developed the silicon rubber for moon walking boots and invented the material for the super-strong fish bowl visors on the astronaut’s helmets.

Take a look at what at GE did for the moon landings and other examples of the company’s technology in space.

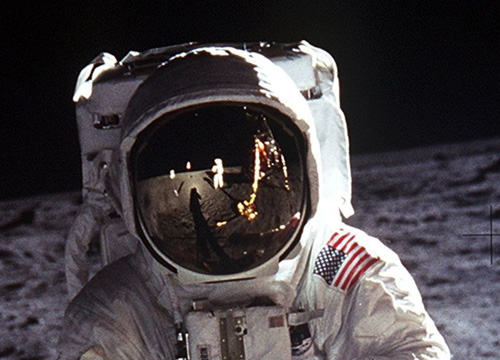

Buzz Aldrin and Neil Armstrong landed on the moon two months after Apollo 10, on July 20, 1969.

They were wearing boots from silicon rubber developed by GE. Image Credit: NASA

The Lunar Landing Training Vehicle, and its predecessor, the Lunar Landing Research Vehicle, were developed by NASA in the early 1960s to prepare astronauts for the first mission to the moon. Built by Bell Aerosystems, the vehicles featured a GE CF-700-2V jet engine that pointed downward to cancel out 5/6th of the vehicle’s weight. Two 2250 Newton hydrogen peroxide lift rockets were also used to help simulate lunar conditions.

Three out of the five vehicles that were created crashed during training, with all of the astronauts, including Neil Armstrong in the first crash, ejecting safely. According to Armstrong, the lunar module flew better than the test vehicles, but the test vehicles were vital to the success of the moon landing. In his own words, “What the LLTV gave you was not so much the seat-of-the-pants dynamics as the real-world visual. That and the fact that, if you make a mistake, you can’t hit the reset button.” Read more about the vehicles here. GIFs come from NASA’s Dryden Flight Research Center.

GE computers were continuously monitoring vital booster systems on Apollo 11’s huge Saturn V rocket before liftoff. Image Credit: NASA

The visors of the astronauts’ helmets were made from Lexan, a transparent, super-strong plastic developed at GE Global Research. Image Credit: NASA

Scientists at the GE lab also developed a new geological dating technique for analyzing moon rocks gathered by Apollo astronauts. GE used the rocks to search for clues about the formation of the solar system.

A ship-to-satellite system from GE provided the first simultaneous live transmission of color TV images, newspaper copy and radio commentary from Apollo 11′s splash-down and recovery in the Pacific. Image Credit: NASA

In 1969, GE built an underwater habitat called Tektite I near St. John in the Caribbean. NASA used it to study crew behavior during long-duration space missions. The habitat’s two steel cylinders were connected via a passageway. The program lasted two months and "aquanauts” spent a total of 432 man-hours in the space. Image courtesy OAR/National Undersea Research Program.

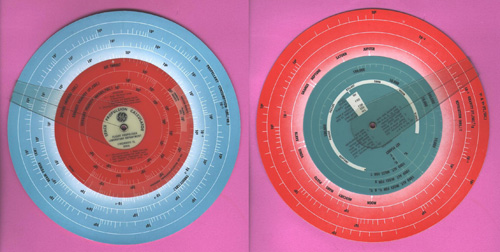

Early in the space program and before the advent of computers, GE created this circular slide rule called the Space Propulsion Calculator. The front can calculate rocket thrust, propellant consumption, specific impulse and exhaust velocity. The gadget lets users compute numbers for chemical and nuclear propulsion as well as the futuristic photonic, magnetohydrodynamic and ion drives. The back of the slide rule offers calculations for planetary data like revolutions, gravity and astronomical constants. Production date unknown. Image courtesy International Slide Rule Museum.

NASA's Voyager 1 and Voyager 2 spacecraft, which launched in 1977, are currently exploring the edge of the solar system. GE engineers designed the Voyagers’ command computers directing their flight path and providing communication links with NASA Mission Control. They also developed the probes’ s electricity generator powering instruments, computers, radio and other systems.

The Voyagers have sent back detailed images of solar system planets and their moons, confirmed the existence of Neptune’s rings, and gathered data about stars near the edges of the Milky Way among a multitude of other data.

GE engineers led the design, integration and testing of the 14-foot, 4,400-pound Landsat 4 and Landsat 5 satellites that photographed Earth from 1982 until 2012. GE also managed the flight and ground missions of the spacecraft, and the company’s digital image analysis lab in Lanham, Maryland, processed their images to reveal details as small as 30 meters long, such as highways and bridges. In March 2012, Landsat 5 entered Guinness World Records as the “longest-operating Earth observation satellite.” The spacecraft was designed for a three-year mission but served for nearly 30 years. This time-lapse compiled from Landsat photographs shows the rate of Dubai’s growth at one frame per year from 2000 through 2011. Image Credit: NASA

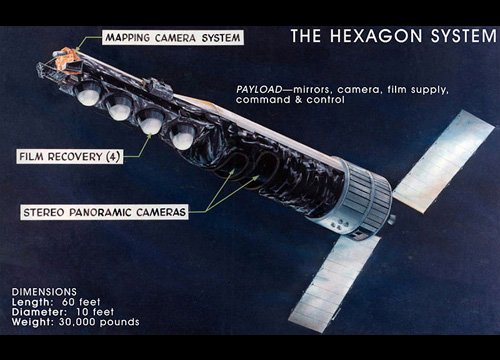

The Hexagon and Gambit were among the largest spy satellites ever built. They were the size of a tractor trailer, 10 feet in diameter and 55 feet in length. GE engineers designed and built image recovery vehicles for the satellites, command systems, mission planning software and other systems. The top secret spy satellite programs ran from 1963 to 1986. In 1984, President Reagan commended the engineers and others who worked on the satellites. But the presidential honor remained secret until 2011, when the program was declassified.

After the Space Shuttle Columbia disaster, GE scientists, in collaboration with NASA and industry partners, helped design and fabricate unique patches to repair damage on the shuttle’s wings and belly in space. The patches were made from a special ceramic composite material that could survive temperature swings from minus 250 degrees Fahrenheit in orbit to a 3,000-degree inferno caused by the drag of Earth’s atmosphere during the shuttle’s 17,000 miles-per-hour descent. Similar heat-resistant materials now serve inside next-generation jet engines like the LEAP.