Jet engines come in all shapes and sizes. Fighter jets use sleek and narrow supersonic engines called low-bypass turbofans to generate enormous thrust. But they also guzzle plenty of gas. Passenger planes use their bigger and more efficient cousins, called high-bypass turbofans. But they are not nearly as fast.

Now engineers at GE Aviation and the U.S. Air Force Research Laboratory are working on the world’s first engine that combines the best features of both designs. “We are making a generational leap with this technology,” says Dan McCormick, manager for adaptive cycle engine programs at GE Aviation. “We are looking at speed and performance, but also fuel savings of 25 percent. That extra fuel could increase how far a military jet flies by up to 35 percent. That’s huge.”

The new design is called “adaptive cycle” engine. It can switch between high power and high efficiency modes. “It’s all about getting as much work as we can out of every drop of jet fuel we burn,” McCormick says.

The adaptive cycle engine is building on decades of military and civilian jet engine research. Innovative architecture shifts air flow between the core, the main bypass, and a third stream to achieve thrust, optimal performance, and fuel efficiency.

The idea dates back to the 1960s, when jet engine pioneer Gerhard Neumann realized that he could manage jet engine performance by controlling the amount of air that flows through the engine core. More flow yields more thrust and speed (that’s good for fighter jets); less flow saves fuel.

GE’s adaptive cycle engine automatically flips between the two modes and gives fighter pilots the speed they need during dogfights, and the fuel savings when they are flying patrols. “We want the engine to take care of itself and let the pilot focus on the mission,” McCormick says. “When the pilot says ‘I’m out of danger, I want to cruise home,’ the engine reconfigures itself.”

The new adaptive cycle engine is building on the YF120, GE’s first variable cycle engine prototype (above on a test stand at Edwards Air Force Base).

In the 1990s, GE engineers built and flight-tested an early prototype of a variable engine, called YF120.

The team is now testing GE’s latest adaptive cycle engine design called ADVENT (ADaptive Versatile ENgine Technology), at the company’s aviation plant in Cincinnati, OH. It includes new heat resistant materials called ceramic matrix composites (CMCs) and 3D printed parts.

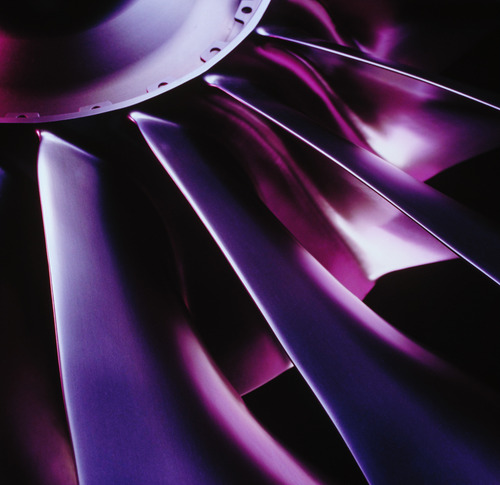

A bladed disk, or blisk, from the YF120 engine.

The team recently achieved the highest temperature ever recorded inside a jet engine core, surpassing engine target temperatures by more than 130 degrees Fahrenheit. This achievement (validated by the Air Force) is a game-changer because more heat equals more power, resulting in greater fuel efficiency.

Adaptive-cycle technology has applications that reach beyond the military. “The latest GE jet engines like the GE9X will use CMCs and 3D printed parts,” says Dave Jeffcoat, ADVENT project manager at GE Aviation. “The tests show that we’ve picked the right technology. We are building on a solid foundation.”

An assembled version of the new adaptive engine.