If the idea worked, the GE team reasoned, the lighter composite blades would shave hundreds of pounds off of each engine, and allow engineers to design a bigger machine with more thrust. “But it was a really tough sell,” says Nick Kray, a consulting engineer for composite design at GE Aviation, who joined the effort early on. “People weren’t initially so hot about the idea. Nobody had tried this before.”

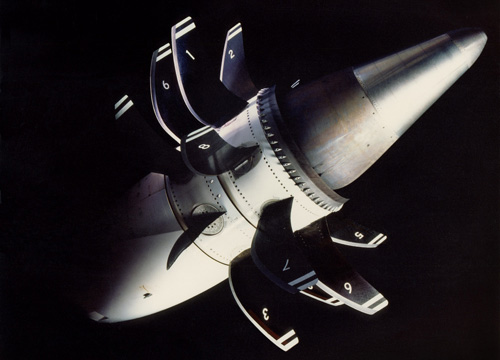

The team wasn’t starting completely from scratch. In the 1980s, the company developed the experimental GE36 open rotorengine (see above). It used carbon fiber composite blades in an unusual hybrid design that combined features from turbofan and turboprop engines. Although the engine demonstrated fuel savings of more than 30 percent compared with similarly sized conventional jet engines, it didn’t catch on.

Back in the lab, challenges popped out behind almost every test. Typical titanium blades absorb energy and bulge when they hit an obstacle like a bird. But ordinary composites can delaminate and break. “We didn’t know how this new material would respond to stress,” Kray says.

The team ran hundreds of intensive tests simulating bird strikes, rain, snow and hail storms at GE’s jet engine boot camp in Peebles and the Wright Patterson Air Force Base, both in Ohio. “We’d test almost daily and make changes based on what we learned,” Kray

says. “The results gave us enormous confidence in the material when we saw how

durable it was.”

By 1993, the team had the right material and blade design, but they were far from done. Now they had to produce it. GE Aviation decided to team up with its European jet engine partner Snecma. The French aerospace company was experienced in making in high-tech composites. They formed a joint-venture called CFAN and built a new composites factory in San Marcos, Texas.

Even with help, making the blade was a hard climb. “The manufacturing of composites

remains a manual process,” Kray says. “The material goes through chemical

changes and tends to move around. We had to learn how to get it right.”

The workers

inspected every single blade with X-rays, ultrasound, laser and other tools for

defects. Initially, only 30 percent of them passed (the current yield is about

97 percent)

The Texas workers weren’t learning about composites alone. GE also had to explain the material to regulators, and even to Boeing, who wanted to use it on its 777 long-range jet. The first one was scheduled to leave its plant in 1995. “On top of everything, we were racing against time,” Kray says. “It was a very steep learning curve.”

Ultimately,

the wager has paid off. Even though the engine had a fan with 128 inches in

diameter, the composites shaved 400 pounds off the machine. The Federal Aviation

Administration certified the engine, called GE90, and the composite blades in

February 1995. “The engines essentially opened the globe up to incredibly

efficient, twin-powered, wide-body planes,” says David Joyce, president and CEO of GE

Aviation.

The engine

wasn’t shy about showing its power and grace. In December 2002, the GE90-115B

version of the engine entered the Guinness list of world records as the most powerful jet

engine ever built, generating thrust in excess of 127,000 pounds – more than

early space rocket engines. In 2005, a GE90-powered Boeing 777 set another world record, this time for distance traveled non-stop by a

commercial jetliner. The plane covered 11,664 nautical miles between Hong Kong

and London in 22 hours and 42 minutes. In 2007, the Museum of Modern Art in New

York included the curved composite blade in its design collection.

Even after 20

years, GE is still the only jet engine maker with engines using composite

blades in service. Kray and other engineers are currently working on a

fourth-generation blade for the GE9X engine for the 777’s successor, Boeing

777X. That plane

will be the largest and most efficient twin-engine jet in the world.

New advances

in composites technology have allowed the team to make an even bigger engine –

the GE9X’s fan diameter will be 134 inches – with fewer thinner and stiffer blades.

(The GE9X will have just 16 blades, compared to 22 on the GE90.)

“Next-generation

composites will go even further,” Kray says. “We are never going back to metal.”

Image credits: GE Aviation