Thomas Edison was not the first engineer to build a working light bulb and the Wright brothers were not the first aviators to fly an aircraft. But like Edison, they took an abstract idea and made it practical.

Edison came up with a carbon filament that made bulbs shine reliably for days. Orville and Wilbur Wright completed the first self-powered flight and invented the airplane. Their achievement was so momentous that in 1939 FDR chose to celebrate August 19, Orville Wright’s birthday, as National Aviation Day.

The innovative legacy of the Wrights and Edison now resonates inside a single company. GE, established by Edison, built the first American jet engine. Today, GE makes the most powerful jet engines from futuristic materials, designs technologies that make flying cheaper and more efficient, and helps planes land at some of the most forbidding airports. Take a look at our slideshow.

GE’s latest jet engine, LEAP, uses parts made from revolutionary materials called ceramic matrix composites, or CMCs. The ceramic can handle the punishing forces inside a jet engine at temperatures as high as 2,400 degrees Fahrenheit. Since CMCs are also a third lighter than conventional alloys now used to make jet engine parts, they can shave hundreds of pounds from a jet engine and reduce fuel burn. GE developed the LEAP in a joint venture with France’s Snecma called CFM International.

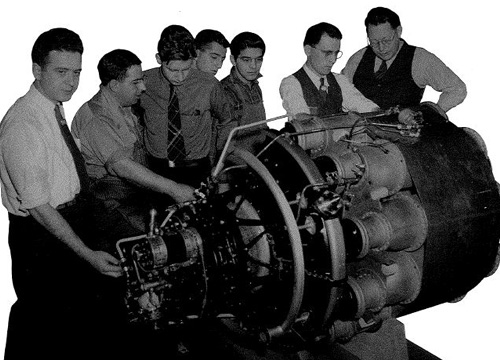

They called them the Hush-Hush Boys. In 1942, a top-secret group of GE engineers build the first American jet engine.

Unlike any other jet engine in history, the LEAP engine also uses metal fuel nozzles “printed" by lasers by adding one layer on top of another. CFM has already received orders for more than 4,500 LEAP engines. The company plans to start ground testing the first full LEAP engine for Airbus A320neo aircraft this September.

The GE90-115B jet engine is the most powerful jet engine ever built. At a 2002 test stand, it generated 127,900 pounds of thrust, earning it an entry in the Guinness Book of World Records (that’s more than the combined total horsepower of the Titanic and the Redstone rocket that took Alan Shepard to space). One of the engine’s blades made from advanced carbon fiber composites is now part of Architecture and Design Collection at New York’s Museum of Modern Art.

The GE90’s successor, the GEnx, was developed for Boeing’s 787 Dreamliner aircraft. A GEnx-powered Dreamliner now holds world speed and distance records on a round-the-world flight for its weight class. This GEnx engine is powering through a water ingestion test at GE Aviation’s testing site in Peebles, Ohio.

When New Zealand’s Queenstown airport switched on a new data-based GE navigation system last year, the technology cut monthly cumulative delays from 2,400 minutes to just 200 minutes. Less holding pattern meant fewer gallons of fuel burned and lower emissions. The system, called Required Navigation Performance or RNP, relies on GPS signals rather than ground based beacons. It is an example of how airlines and airports can tap the power of data to improve operations. James Fallows, an aviation reporter and China expert, wrote that before RNP, much of western China was “effectively beyond the range of reliable air travel.“ GE has recently launched GE Flight Quest and challenged data enthusiasts and coders to use big data sets like flight routes, weather, plane and airport system data, and design a solution that would maximize flight economics by telling the pilot the optimal route to fly a plane.

Running a leaner, more efficient airline does not have to involve spending capital on the latest, most efficient planes. A little bit of jet engine brain surgery can do the job. GE engineers have developed a brainy software system called Fuel and Carbon Solutions that crunches aircraft data, from jet engine performance, fuel burn and plane location to information coming from digital flight data recorders. GE estimates that the system can cut an airline’s fuel bill by up to 3 percent. That may not seem like much, but consider fuel costs can reach between 30 to 44 percent of an airline’s operating expenses. China Airlines and other oerators have signed up to use the system.