The Maker Movement is a vast and diverse community teeming with passionate hobbyists and DIY entrepreneurs energized to build new products and open their designs to others to improve upon them. They share an infectious innovative ethos that anybody can learn from.

Last month, GE challenged the Maker community to use 3D printing to manufacture complex parts for medical equipment, and to redesign a bracket used for manipulating jet engines and make it 30 percent lighter. “We want to develop an ecosystem of designers, engineers, materials scientists, and other partners who can learn with us,” says Michael Idelchik, who runs GE’s advanced technologies research. “We have a number of products that we are going to be launching and we want to challenge people to get into business with us. If the ecosystem grows, the entire industry will grow.”

GE calls these challenges “quests.” They are both open and submissions are rolling in. The company has already received hundreds of entries in the bracket challenge alone. GE and partnerGrabCAD will manufacture and test the top 10 bracket designs. The winners will receive $1,000 each. The eight designs that perform the best in tests will divide an additional $20,000 prize pool.

The top 10 entrants in the medical manufacturing quest will receive $5,000 each. GE and Nine Sigma will invite the winners to produce the parts from materials of GE’s choosing. Up to three winners will then receive up to $50,000 each.

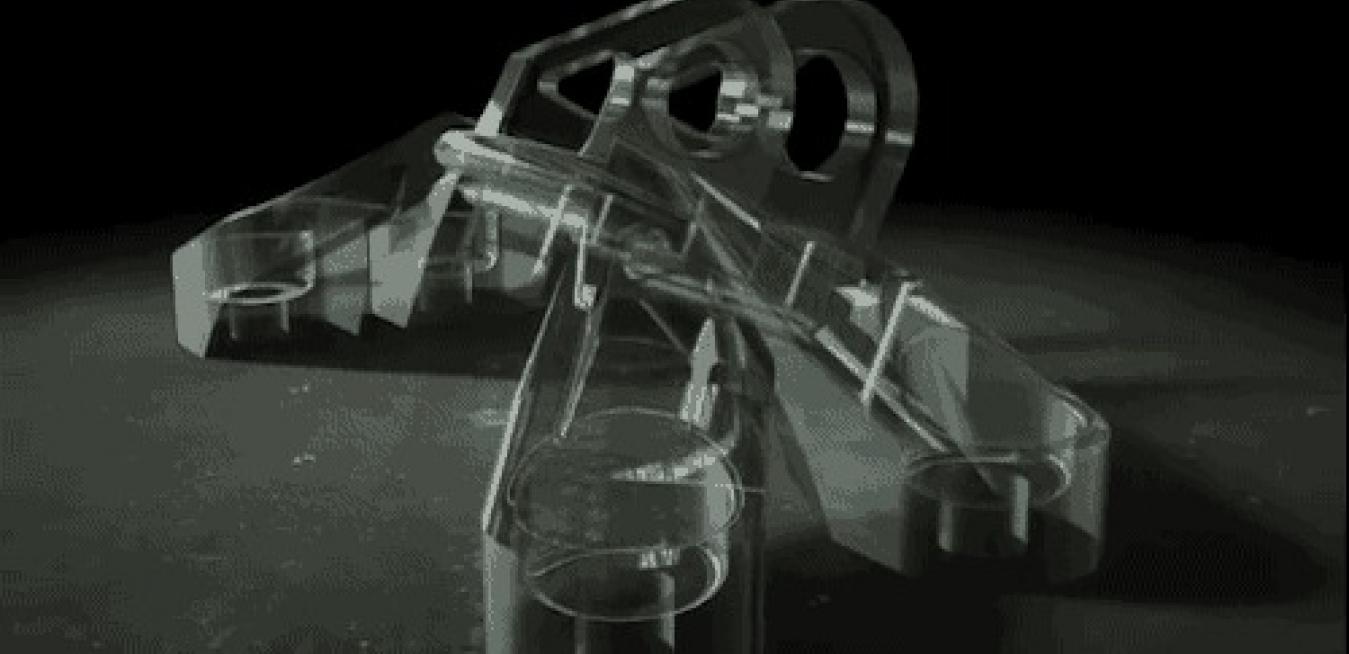

Our slideshow features a selection of bracket submissions. Many entrants have submitted designs with light-weight mesh structure, sinuous forms, and hollowed-out shapes difficult to make with traditional machining tools but well suited for 3D printing.