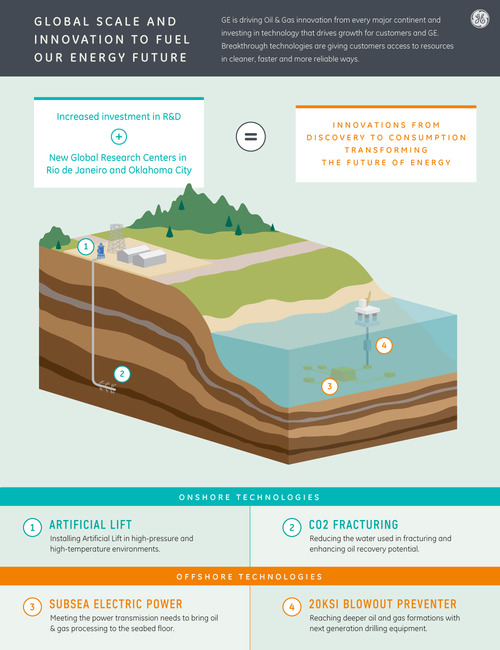

“The vast majority of existing fracturing operations now pump in millions of gallons of pressurized water to do the job,” says Mike Bowman, an engineer in the sustainable energy advanced technology lab. “But the new process could one day eliminate the need for it and make fracturing cleaner and more effective.”

Bowman works at GE’s research headquarters in Niskayuna, NY, but he will soon have dozens of new colleagues at a $125 million global oil and gas technology hub that GE started building in Oklahoma City today.

Click here to download

Scientists at the hub will be developing advanced pumps that can increase the flow of oil and gas out of the ground, well designs with a smaller environmental footprint and technologies for CO2 capture, transportation and storage.

GE scientists will be working at the center with customers and industry partners like Devon Energy, Continental Resources and Chesapeake Energy to bring their research more quickly to market. “At GE, we look at innovation through a broad lens,” said Mark Little, GE’s chief technology officer.

GE Oil & Gas is GE’s most dynamic business. It had $17 billion in global revenues and 13 percent earnings growth in 2013.

The expansion reflects growth in global demand for energy. For example, experts estimate subsea production will increase 35 percent by 2018. The growing demand along with depletion of current wells is driving production toward deeper parts of the sea. Some 450 deepwater fields will start producing over the next six years. Capital invested in wells is expected to double from today’s levels of more than $100 billion over the same period.

A unit from the lower stack of a blowout preventer at GE Oil & Gas in Houston.

GE has invested $14 billion in the Oil & Gas business since 2007 and plans to triple R&D spending in the sector over the next three years.

The Oklahoma hub will join a global network of seven other GE research centers located in India, China, Germany, Brazil and the U.S. “We are a core of high-end scientists and engineers who support every GE business from healthcare to energy to oil and gas,” Little says. “We are here for one purpose: Change the world and make our businesses great.”

GE engineers have already started connecting huge blowout preventers (BOP) stationed at the seafloor to the Industrial Internet to analyze and collect the data they produce. “We need to move from the ‘break-fix’ model to a predictive maintenance model,” says Bob Judge, director of product management at GE Oil & Gas. Judge says it costs between $10 million and $16 million to raise a BOP for repairs and maintenance. Instead, predictive maintenance could save drilling companies millions in unplanned downtime.

Working with partners like Oceaneering and BP, GE engineers have also combined advances in medical X-ray technology to spot cracks in subsea pipelines before they break. Coatings developed by aviation engineers could soon start protecting machines submerged deep in cold salt water.

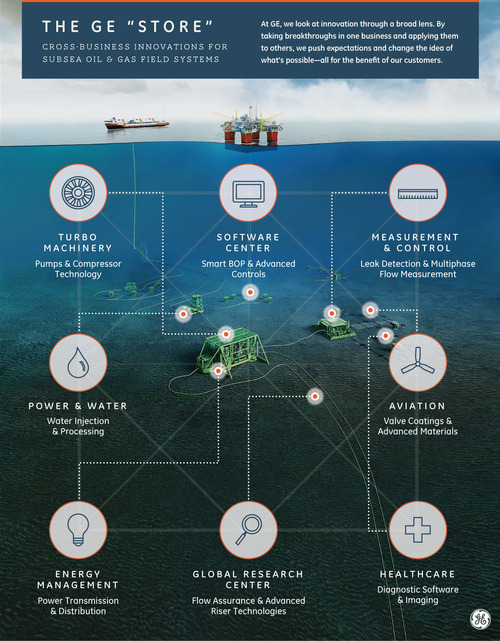

“We can draw on the ‘GE store’” to deliver better outcomes to customers, Jeff Immelt, GE chairman and CEO, wrote in his annual letter to shareowners. “Gas turbine technology, aviation materials, healthcare imaging, global capability…we can leverage our enterprise advantages as we win in new infrastructure markets, like oil and gas.”