June 2, 2020

THE ROBOTIC UNDERGROUND

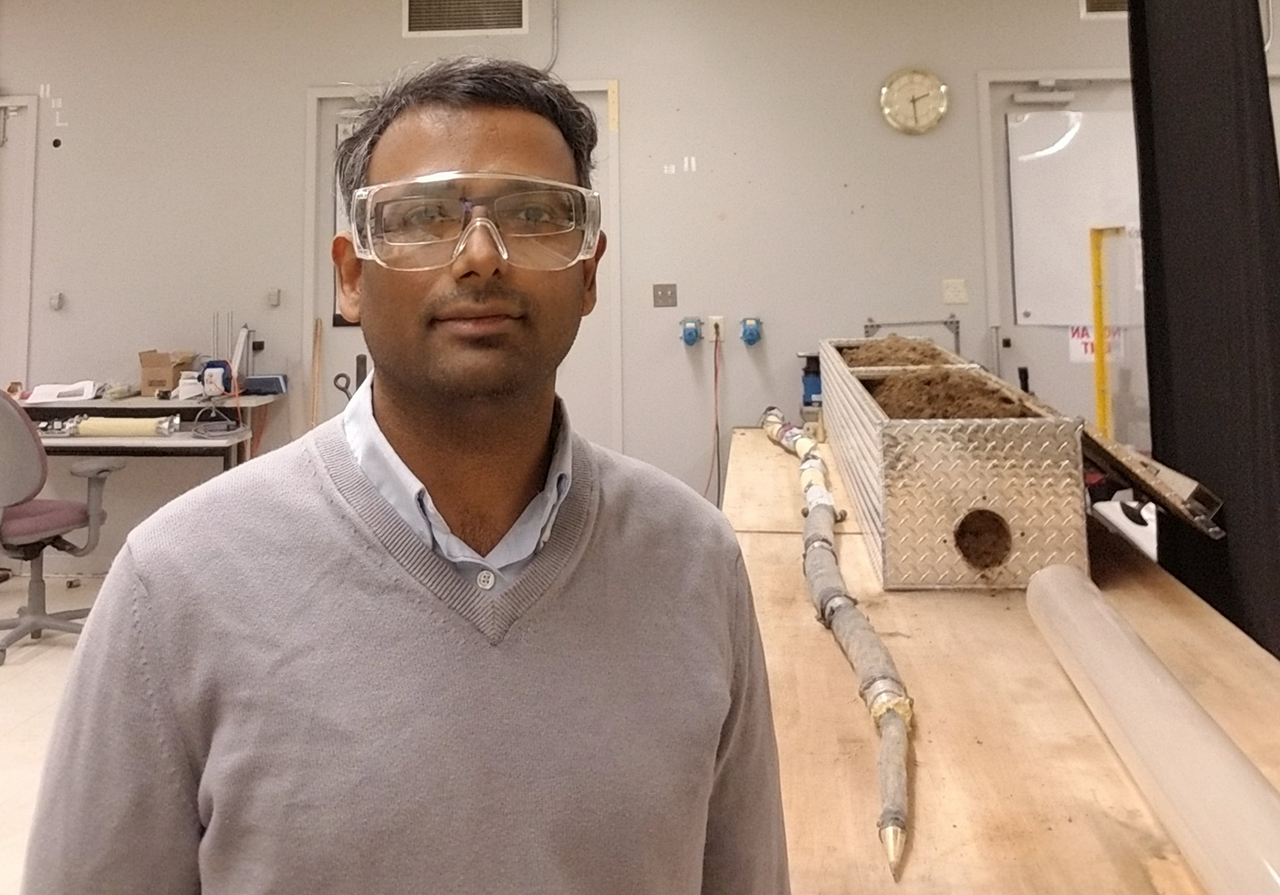

If you saw a 6-foot earthworm popping up out a tunnel it had just dug, you might express some surprise — but don’t worry, this worm is here to help. At GE Research in Niskayuna, New York, Deepak Trivedi and his colleagues have been working on a soft, bio-inspired robot as part of a $2.5 million, 15-month project funded by the Defense Advanced Research Projects Agency’s Underminer program. The idea is to create a burrowing machine that could one day save lives — say, by tunneling in to resupply troops.

Machine worming: Earthworms are small but mighty, able to leave a tunnel twice their diameter in the dirt they’ve dug through. Trivedi, an expert in soft robotics, has drawn inspiration from the worms’ internal dynamics among other physical attributes. In the prototype he and his colleagues are working on, fluid flows inside seven internal chambers that act as muscles, flexing as water is pumped in and out. The machine’s nose contains a piloting tool to stir and soften the earth as it moves forward. Once it’s fully operational, the robot’s engineers expect the Underminer to be able to dig a tunnel longer than five football fields in just 90 minutes. “There’s something beautiful in the mathematics and the biological examples used in understanding these soft structures,” Trivedi said. “In addition to being able to make something really cool, really fast.”

Dig into the story here.

THE QUESST FOR SPEED

For decades, the Federal Aviation Administration has banned civilian aircraft flying over land from exceeding the speed of sound due to a loud boom created when an aircraft breaks the sound barrier. But some aviation engineers have thought of that ban as a challenge: Can they create a plane that flies faster than the speed of sound but doesn’t make such a ruckus about it? Now the race to create a new, quieter supersonic plane has entered a new phase. Last month, GE Aviation shipped its first engine for NASA’s X-59 QueSST, an experimental aircraft designed to fly faster than the speed of sound and cruise at 55,000 feet — but do it more quietly than its predecessors.

Shhhhhhh: Designed by NASA and Lockheed Martin, the X-59 QueSST (short for Quiet Supersonic Technology) made Popular Science’s list of 100 Greatest Innovations of 2019. The craft’s unusual shape, the magazine explained, means noise more on the order of “far-away thunder or a dull thump” when it goes supersonic. For its part, GE Aviation is supplying the F414-GE-100, a new single-engine variant of its fighter jet engine the F414. The engine will provide the X-59 with its traditional 22,000 pounds of thrust, while also integrating single-engine safety features. The ultimate goal of the X-59 program? Gathering enough data on supersonic flight to help open a new era of commercial aviation — with coast-to-coast flight times, for instance, cut in half.

Learn more here.

VIRTUAL LEAN

Recently, GE Reports visited GE Gas Power’s turbine factory in Greenville, South Carolina, which used lean, the legendary set of management principles centered on continuous improvement, to cut a production line from more than 3 miles to a mere 165 feet. Lean involves techniques like Lean Action Workouts — weeklong, in-person gatherings dedicated to establishing or improving a process, machine or way of thinking. In the first half of 2020, GE Gas Power planned to hold more than 50 such workouts around the world. COVID-19 changed that.

The show must go on: Changed — but didn’t stop. Richard Simpson, GE Gas Power’s vice president of global supply chain, and Karen Hoyle, global lean leader at GE Power, explain in a new article on LinkedIn how workouts have been adapted to meet the needs of the moment. “While our operations are considered essential to power and infrastructure, we had to change the way we work,” the pair write. Workouts went online: Using interactive video and other virtual tools, teams have completed 39 Lean Action Workouts so far in 2020. Last month, 10 factories and repair operations participated in the first-ever Asia Lean Week. “No matter the environment, cost pressure or pandemic, we are committed to pushing forward, adapting with lean and continuing to improve problem-solving,” Simpson and Hoyle write.

Learn more about how they did it here.

WAYS THE WORLD ? FOUGHT BACK

1. Gown And Country

After attending a virtual ceremony, a newly minted MBA holder from the University of Vermont decided to repurpose his graduation gown into personal protective equipment for healthcare workers fighting COVID-19 — and encouraged thousands of others to do the same.

2. Antibody Defense

An antibody identified in the blood of a patient who recovered during a previous coronavirus outbreak — the SARS epidemic of 2003 — could be used to treat patients infected with the current coronavirus, according to a new study in Nature.

3. Vaccines That Work

A new paper by MIT economists argues that “the probability of success for vaccines is reliably higher” than the development of other types of drugs — but that the field of vaccine development needs investment.

Click here for more promising developments in the fight against the COVID-19 pandemic.

— QUOTE OF THE DAY —

“Some of these new ideas open up an entirely new world for exploration and innovation.”

— Deepak Trivedi, mechanical engineer at GE Research

Quote: GE Reports. Image: GE Research.

ENJOY THIS NEWSLETTER?

Please send it to your friends and let them know they can subscribe here.