As a modern-day wonder of reinvention, Japan’s power sector rivals David Bowie, Madonna and Prince. In the decade prior to 2011, fossil fuels and nuclear power dominated the country’s grid, generating close to 90% of the island nation’s electricity. But following the devastating tsunami in 2011, Japanese authorities shut down the country’s 11 nuclear reactors (which represented about 30% of Japanese electricity at the time) and boosted imports of liquified natural gas (LNG), fuel oil and coal to burn in the country’s power plants.

It created a significant negative impact on the CO2 footprint of the Japanese electricity sector. To counter this effect, the government followed up in 2015 by proposing an ambitious goal of growing up to 24% of the nation’s electricity from renewable sources by early 2031.

So far, Japan has lifted the share of renewables on its grid from just under 13% in 2011 to 16% in 2018. And the relatively young Japanese renewables sector, which mainly consists of hydroelectricity, solar, geothermal and wind facilities, includes a technology that is older than our species: biomass.

A quick primer: Biomass is organic material from plants and animals that humans burn to produce energy. Homo erectus learned how to harness the flames of burning wood to provide warmth and heat food around 1.7 million years ago, but these days biomass consists of woody plants or herbaceous crops such as willow, poplar and elephant grass, and the biogas captured from rotting food and animal manure.

You might wonder how biomass is a renewable fuel, given that burning any organic material emits carbon dioxide just like oil, gas or coal. Sacha Parneix, chief commercial officer of GE’s Steam power division, explains the plants, trees and crops that are burned as biomass have also absorbed carbon dioxide for photosynthesis throughout their short lifetimes. This means that, even before being burned, they’ve already offset their emissions. “Do the math and the equations, and you end up with a near-carbon-neutral process that also generates kilowatt-hours of electricity,” Parneix says.

As long as humans continue to replace the forests and sugar cane plantations that they burn, then, biomass can form part of a renewable cycle. Within this sustainable plantation context, the United States, the European Union and the United Nations recognize plant-derived biomass as a renewable source of energy.

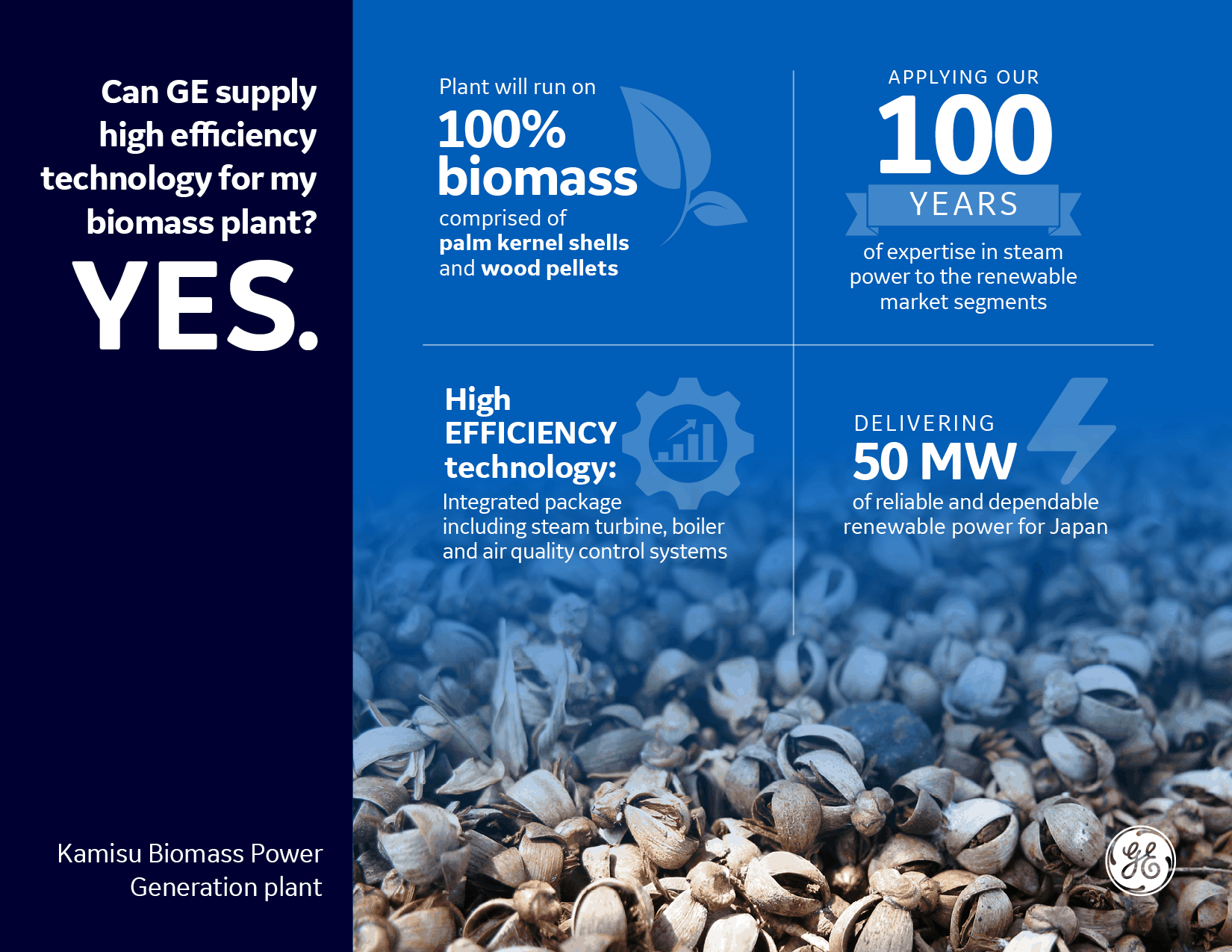

That is exactly what is happening in Kamisu, a small city on Japan’s eastern coast, where GE Steam Power has signed a deal with Hitachi Zosen Corporation to design, manufacture and supply the main parts of a power plant that will burn plant-derived biomass to produce 50 megawatts of electricity for the country’s grid.

Above: Biomass is organic material from plants and animals that humans burn to produce energy. Homo erectus learned how to harness the flames of burning wood to provide warmth and heat food around 1.7 million years ago, but these days biomass consists of woody plants or herbaceous crops such as willow, poplar and elephant grass, and the biogas captured from rotting food and animal manure. Top image: The palm kernel shells and wood pellets are burned in a boiler to heat water and produce steam, which flows into a turbine at high pressure, spinning a generator to produce electricity on the grid. The steam is then cooled, condensed back into water and returned to the boiler to start the process over in a closed water cycle. Image credits: GE Steam Power.

Kamisu will burn a mixture of palm kernel shells, the waste product from palm oil production, and wood pellets, which are made from the waste product from timber mills. The near carbon-neutral cycle is then closed: some sustainable plantation and its waste used to generate dependable electricity.

Admittedly, power generated from biomass is not the cheapest cost of electricity production but it provides dependable capacity — and counterbalances the natural intermittency (and resulting grid instabilities) from other renewable sources of energy like sun or wind. That is why Japanese authorities are providing an economic incentive for the electricity production from biomass with a feed-in tariff of 24 yen per kilowatt-hour paid to generators. “Without that subsidy, many projects might not be economic, but the country wants to meet its renewables targets and needs to value the dependability of power generation,” says Parneix.

While plant-derived biomass is almost carbon neutral, it is at the exact opposite side versus coal on the scale of net carbon emissions. But the process of extracting energy from both fuels is the same. The palm kernel shells and wood pellets are burned in a boiler to heat water and produce steam, which flows into a turbine at high pressure, spinning a generator to produce electricity on the grid. The steam is then cooled, condensed back into water and returned to the boiler to start the process over in a closed water cycle.

That’s a process in which GE has unrivaled experience. “We have been at the leading edge of steam power technology for over a century,” says Parneix. “The fuel in the boiler may be different, and even carbon neutral, but the process is the same.”

Kamisu will use a circulating fluidized bed (CFB) boiler, which churns the unburned biomass chunks and embers — like stoking a fire — until they’re completely combusted. A stable, slow-burning and relatively cool fire, as opposed to a roaring inferno, also minimizes the unwanted nitrate oxides (NOx) that would otherwise be generated through high flame temperatures. Image credit: GE Steam Power.

Still, not all fuels burn in the same way. Biomass may be relatively slow-burning and requires plenty of space to combust effectively. Kamisu will use a circulating fluidized bed (CFB) boiler, which churns the unburned biomass chunks and embers — like stoking a fire — until they’re completely combusted. A stable, slow-burning and relatively cool fire, as opposed to a roaring inferno, also minimizes the unwanted nitrate oxides (NOx) that would otherwise be generated through high flame temperatures. “The lower the temperature, the lower the levels of thermal NOx,” says Parneix. He explains that combustion in GE’s biomass-burning CFB is typically around 800-850 degrees Celsius; in a standard boiler, the temperature can reach 1,500° C. Those smaller numbers translate to cleaner air for the people who live in and around Kamisu, a city with a population of nearly 100,000.

Kamisu is also equipped with dust-removal filters that prevent the fine particles in the flue gas from escaping out of the plant’s smokestack and into the surrounding air. “They are fabric bags which collect and store the dust from the flue gas sustainably,” says Parneix.

Because biomass won’t produce the lowest cost of electricity generation, it may not be an option for cash-strapped countries, Parneix concedes. But plant-derived biomass has a big role to play in relatively wealthy regions that are seeking to slash their CO2 emissions and can afford a rapid and sustainable transition to renewables. “This explains why nowadays mainly OECD-type countries like Japan, South Korea, Europe and North America are planning new-built capacity for biomass power,” Parneix says.