Jeff Immelt, GE chairman and CEO, writes in the company’s 2013 Annual Report, which GE released today, about the benefits of looking at innovation with a broad lens.

The theme of the Annual Report, and Immelt’s letter to shareowners, is “Progress,” which, he writes, is reflected in GE’s ability to spread ideas and technology across the entire company.

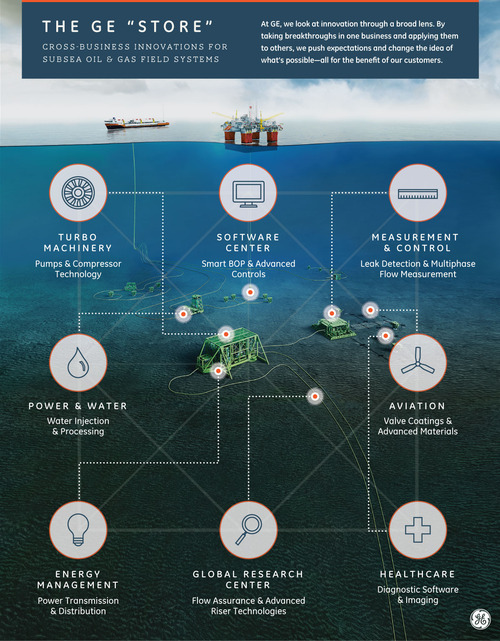

“We can draw on the ‘GE store’” to deliver better outcomes to customers, Immelt writes. “Gas turbine technology, aviation materials, healthcare imaging, global capability…we can leverage our enterprise advantages as we win in new infrastructure markets, like oil and gas.”

Few places are more extreme than the bottom of the ocean. But GE engineers have been pooling knowledge and building machines that can help oil and gas customers detect problems before they get out of hand and minimize unplanned downtime.

This means that advances in medical X-Ray technology could help spot cracks in subsea pipelines before they break. Coatings developed by aviation engineers could start protecting machines submerged deep in cold salt water.

Elsewhere, algorithms written by software engineers in Silicon Valley could help monitor blowout preventers (BOPs) built by GE Oil & Gas workers in Texas.

BOPs are 50,000-pound, 60-foot-tall safety valves made from 70,000 component parts. They sit on top of pressurized oil and gas wells thousands of feet below the surface of the ocean. They serve as the last line of defense if something in the well goes wrong.

Many BOP parts have different lifespans and the massive machines have to be periodically pulled up and serviced. But GE workers are developing Big Data technology that could give customers information about real-time performance.

“We need to move from the ‘break-fix’ model to a maintenance model where we can advise customers to service a component based on measurements of its performance,” says Bob Judge, director of product management at GE Oil & Gas. “What if you had technology gathering BOP data so that the next time you pull it out, you know exactly what needs to be replaced and have the replacement parts available on the drilling rig? This information could save millions of dollars in unplanned downtime, adding substantial value for our customers and for their customers.”

Take a look at our infographic illustrating a vision of the GE Store, connecting innovation across the company.