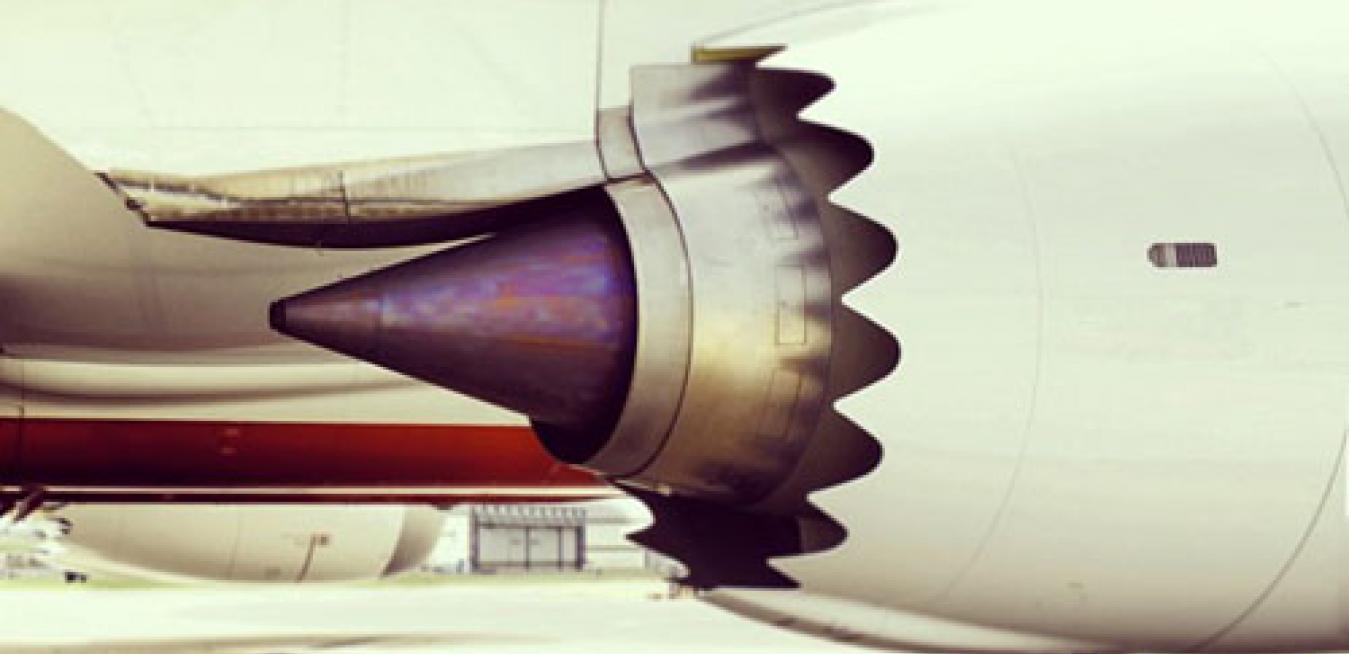

GE now makes the world’s largest and most powerful jet engines, and aviation is a core company business with $20 billion in 2012 revenues and 32,000 engines in commercial service. This year, GE Aviation won its largest contract ever valued at $11 billion at the 2013 Dubai Air Show. In total, GE won $40 billion in new business in Dubai, making it the most successful showing in its aviation history. Take a look at Dubai and other highlights from 2013:

The GE9X, which is 60 times more powerful than the jet engine built by the hush-hush boys, is still in development. But Emirates, Qatar Airways, and Etihad Airways already agreed to buy 450 GE9X engines valued at $26 billion (including service agreements) for their new new Boeing 777X planes. The GE9X will include advanced technologies and complex components like 3D-printed nozzles, ceramic matrix composites (CMCs) and fourth-generation carbon composite fan blades that make it lighter and more fuel efficient.

Flight Efficiency Services (FES) to help airlines become smarter. “With the combination of historical and current information, we can make optimized decisions about flight plans and fuel load,” says Giovanni Spitale, general manager at FES. “Planes don’t have to carry all that extra fuel weight if they don’t need it. But you have to present the pilot with enough information to make that decision based on science and good data. He ultimately carries the responsibility for the plane.”

Flight Efficiency Services (FES) to help airlines become smarter. “With the combination of historical and current information, we can make optimized decisions about flight plans and fuel load,” says Giovanni Spitale, general manager at FES. “Planes don’t have to carry all that extra fuel weight if they don’t need it. But you have to present the pilot with enough information to make that decision based on science and good data. He ultimately carries the responsibility for the plane.”FES was one of 14 Industrial Internet technologies released this year to help airlines, energy companies, hospitals and other customers cut downtime, improve productivity, save fuel and reduce emissions. GE launched the first 10 Industrial Internet products in 2012. They brought in $290 million in revenues and another $400 million in orders as of November 2013.

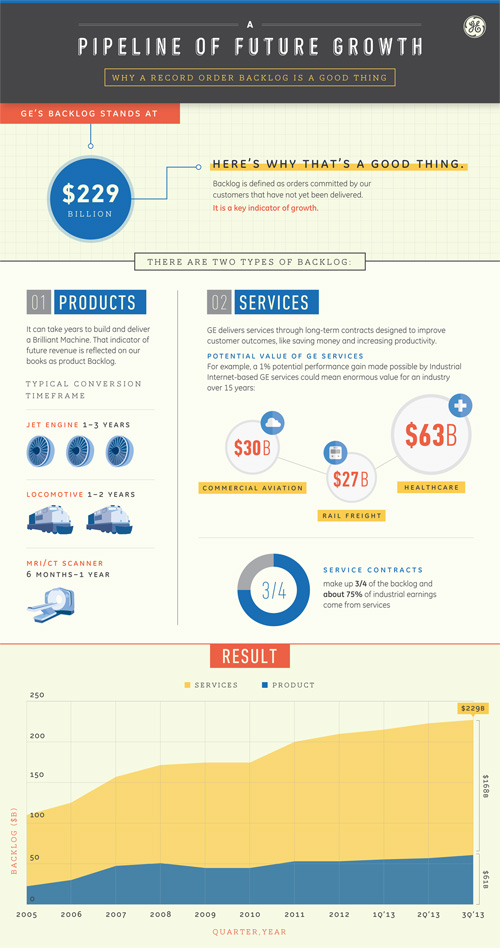

GE’s record-high backlog stands near $230 billion. Accountants define backlog as orders committed, but not yet delivered. Hardware like jet engines and turbines accounts for just a one-quarter share of the backlog. The bulk of the backlog, about three quarters, does not involve big iron at all, but services like FES designed to make customers more efficient and productive.

GE is leveraging the high-margin services backlog to develop more predictive technologies and grow software sales. “Industrial data is not only big, it’s the most critical and complex type of big data,” said Jeff Immelt, GE chairman and CEO. “Our greatest challenge and opportunity is to manage and analyze this data in a highly secure way to deliver better outcomes for customers and society.”

A recent story in Barron’s made the same observation and noted that GE was “transforming itself into a seller of services rather than just equipment.”

“Airlines can use data from hundreds of GE sensors to reduce fuel costs and plan maintenance,” Barron’s wrote. “Railroads can do the same to optimize trips. Software now contributes $4 billion a year to GE’s revenue. And service contracts create a stream of high-margin income that can last for the life of the equipment the company sells—in some cases, three or four decades.”

powering through tests at GE’s Peebles Test Operation in Ohio.

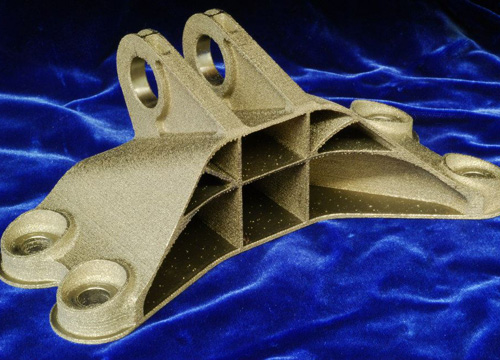

powering through tests at GE’s Peebles Test Operation in Ohio.Anybody can take part in this advanced manufacturing revolution. In June, GE and and the open engineering community GrabCAD launched a 3D Printing Design Quest, and challenged the public to redesign a metal jet engine bracket. The goal was to make it at least 30 percent lighter while preserving its integrity and mechanical properties like stiffness. Manufacturing and maintenance crews use the brackets to manipulate jet engines that weigh as much as 13,000 pounds.

Participants from 56 countries submitted nearly 700 bracket designs to the Quest, and in December GE and GrabCAD announced the winner: an engineer from Indonesia who reduced the weight of the bracket by 84 percent. “We believe additive manufacturing methods like 3D printing will be pervasive,” says Michael Idelchik, who runs advanced technologies research at GE. “We already know that it can be done. But now we have to get the people with the right talents to embrace it and create an ecosystem of designers, suppliers and materials scientists.”

Age of Gas. A new GE study written by Peter C. Evans and Michael F. Farina found that natural gas is becoming a focal point of global energy supply and demand. Gas “is positioned to rival coal consumption as well as take share from oil on the global stage,” the authors wrote. Evans and Farina expect that gas consumption will grow by more than a third from its current level by 2025. They estimate that international trade in liquefied natural gas (LNG) will increase by 70 percent in this decade alone, as gas will increasingly complement wind and other renewable energy sources in power generation.

Age of Gas. A new GE study written by Peter C. Evans and Michael F. Farina found that natural gas is becoming a focal point of global energy supply and demand. Gas “is positioned to rival coal consumption as well as take share from oil on the global stage,” the authors wrote. Evans and Farina expect that gas consumption will grow by more than a third from its current level by 2025. They estimate that international trade in liquefied natural gas (LNG) will increase by 70 percent in this decade alone, as gas will increasingly complement wind and other renewable energy sources in power generation.The authors point out that the “flexibility” of natural gas power plants – they can start up is less that 30 minutes and increase power output at 100 megawatts per minute – could also help utilities incorporate into the grid sources of renewable energy whose output changes quickly with the weather, like wind and solar farms.

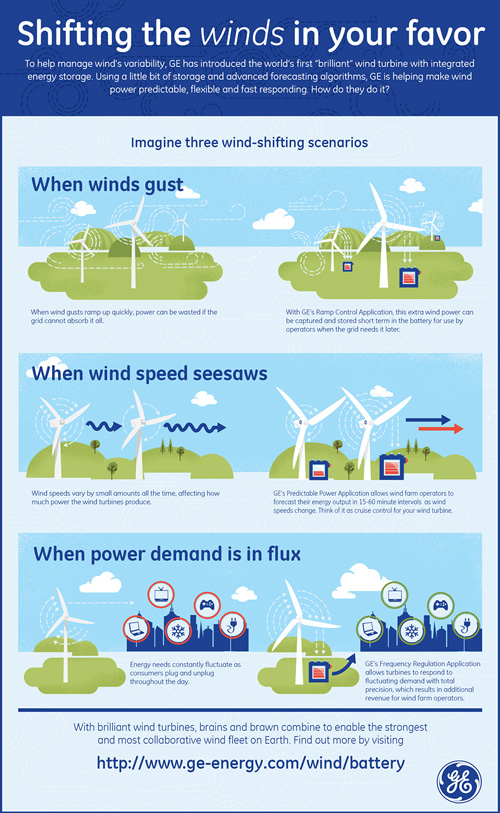

In November 2013, Popular Science magazine included GE’s first wind turbine connected to the Industrial Internet on the magazine’s annual list of “the 100 greatest innovations.” The editors wrote that “with its so-called brilliant turbine GE has cleared two of wind power’s biggest hurdles: energy storage and predictable power.”

The 2.5-megawatt turbine is loaded with sensors and communicates with other turbines at a wind farm via the Industrial Internet, a digital network that links people, machines and software. Advanced forecasting algorithms can estimate how much electricity the turbine will generate over the next hour to maximize production. An integrated battery can store excess electricity and release it later to provide steady output. “This is predictable power,” says Keith Longtin, general manager at GE’s renewable energy business.

“The grid can’t always accept wind power as fast as it comes up,” Longtin says. “At times when it’s gusting, the grid cannot absorb all the power and turbines turn their blades out of the wind to let some of the power pass through. That potential revenue is gone with the wind.” GE’s “brilliant” wind turbines will allow wind farm operators to capture some of the lost energy.

working with entrepreneur Eric Ries to develop FastWorks, a program built on his Lean Startup principles. As the name implies, FastWorks combines a set of tools and behaviors designed to deliver better outcomes for customers faster.

working with entrepreneur Eric Ries to develop FastWorks, a program built on his Lean Startup principles. As the name implies, FastWorks combines a set of tools and behaviors designed to deliver better outcomes for customers faster.The program has the backing of top GE management, including Chairman and CEO Jeffrey Immelt and Chief Marketing Officer Beth Comstock. They saw an opportunity to take many of the aspects of the Lean Startup movement and apply them inside the company. “I tell all of our managers to read The Lean Startup,” Immelt says.

In the first year, Ries trained 80 coaches exclusively dedicated to FastWorks. Together they exposed almost 1,000 GE executives to Lean Startup principles. GE also launched 100 FastWorks projects in US, Europe, China, Russia and Latin America. They range from building disruptive healthcare solutions to designing new gas turbines. GE plans to expand the program to 5,000 executives and launch hundreds of new projects next year. “GE is an ideal laboratory for applying lean practices because of its scale,” Ries says. “This is undoubtedly the largest deployment of Lean Startup ideas in the world.”