Traditionally, a PET scan would show up anomalies in the body, with an injected tracer that targets organs and identifies abnormal activity, but doesn’t pin point its exact location. An MR scan to follow would detail the body’s structure, allowing clinicians to specifically locate anomalies for treatment.

By combining these two technologies into a hybrid imaging system, clinicians can now get a detailed 3D map of the body in one scan, one that shows the skeletal structure, soft tissue, nervous and cardio vascular systems in full detail.

This is medical imaging technology at its most advanced, but it doesn’t arrive ready to go.

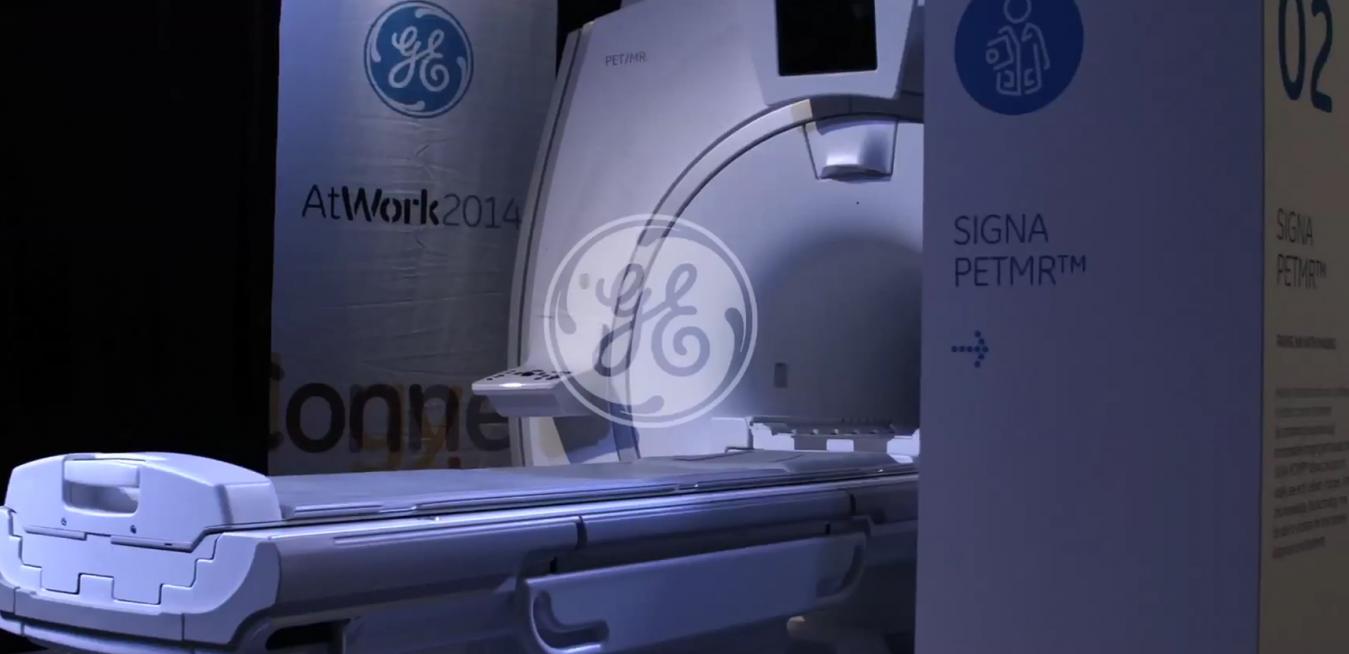

GE Healthcare field service engineer, Kavin Ung, will testify to that. He recently spent six hours assembling just the shell of the GE Healthcare SIGNA™ PETMR. The technology was front and centre at the recent At Work 2014 event in Sydney.

While a six hour build may sound extreme, the real deal in a hospital would take about a month to construct and commission, and there are some unusual logistics involved.

To start with, the technology is usually constructed in a specially prepared open room, which is then built around the finished unit.

And although the shell Kavin built weighs over 250kg, the magnet alone in a fully functioning PetMR weighs in at around 8 tonne. It requires a crane to move and install it.

For Ung, the biggest challenge about building the SIGNA™ PETMR for At Work 2014 was getting it into position. “The real thing involves mechanics, cryogenics, hydro technology, electrical elements– it’s a way more complex process.”

Watch the time lapse to see this spectacular technology come to life.