Work Management Items (WMIs)

About Work Management Items (WMI)

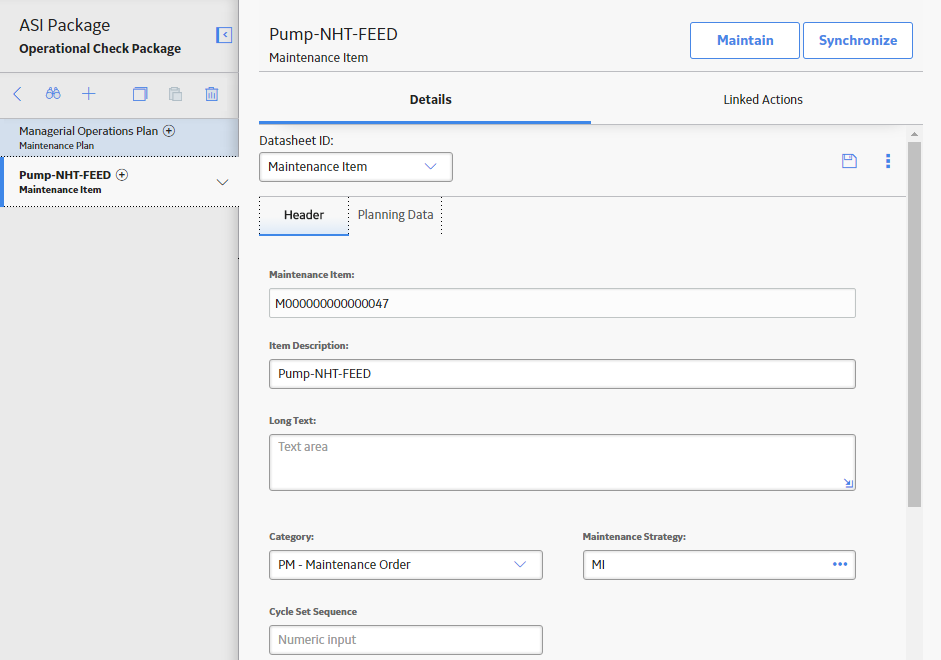

Work Management Items (WMIs) represent the work that should be completed when the Implementation Package is implemented. Throughout the documentation, we refer to them as work management items (WMIs) because they can belong to any family. Before you can create work items in a particular family, the corresponding Work Management Item Definition records and Work Management Item Child Definition records must exist. Each Work Management Item Definition record contains a family ID, which identifies a family to which work items can belong.

GE Digital APM delivers a baseline set of Work Management Item Definition and Work Management Item Child Definitions to allow you to create work items in certain baseline families. For example, GE Digital APM delivers a Work Management Item Definition whose family ID is Maintenance Item, which allows you to add Maintenance Items to an Implementation Package. You can also create your own Work Management Item Definitions so that you can create work items in other families.

After you add a work item to an Implementation Package, the work item is linked either directly or indirectly to the root Implementation Package record. Work items can also be linked to one another and arranged hierarchically in the tree on the Packaging <Package ID> page according to these relationships. Beyond defining the family of the work items that you want to create, you will, therefore, need to define where in this hierarchy they can exist. To do so, you will need to:

- Configure the appropriate relationship definitions via the Configuration Manager.

-and-

- Create the appropriate Work Management Item Definition and Work Management Item Child Definition records via the GE Digital APM Framework.

On the Packaging <Package ID> page, the options that appear in the tree and on the Packaging Tasks menu are dynamic, meaning that they change based upon the current selection in the tree. The options that are available are based upon the way in which you have configured the hierarchy.

Throughout this documentation, we describe the hierarchy that appears on the Packaging <Package ID> page using the terms predecessor record and successor record. In this context:

- A predecessor is any work item to which another work item can be linked.

- A successor is any work item that is linked to a predecessor work item.

About Deleting a WMI

When you delete a WMI from an implementation package:

- The following objects in SAP are deleted:

- Operations

- Maintenance package

- Object lists under maintenance items

- The following objects in SAP are not deleted:

- Maintenance plan

- Maintenance item

- Task lists

These objects are not deleted because SAP does not support deleting these objects via the ABAP code. SAP, however, allows objects to be flagged as deleted.

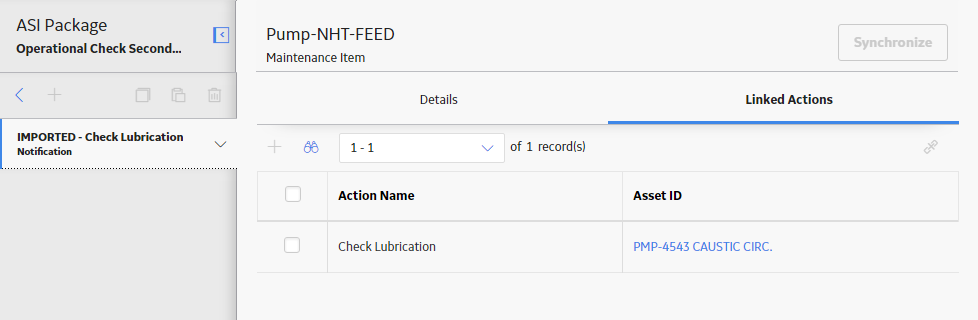

About the Maintain Object List

When using the Maintain Object List feature, the GE Digital APM system searches the Actions that are associated with the selected Maintenance Item record and any Operation record to which it is linked. If those Actions belong to an underlying Asset Strategy that is linked to an Equipment record, one Object List Item record will be created for each of those underlying Equipment records.

This feature ensures that your Object List Item records are always in sync with the actions that are currently part of the Implementation Package. In general, you should use this feature before packaging any Implementation Package.

For example, suppose an Implementation Package contains the following Asset Strategies with the following Actions.

| Asset Strategy | Equipment | Action |

|---|---|---|

| Asset Strategy 1 | Equipment 100 | Overhaul every 5 years |

| Inspect every 1 month | ||

| Asset Strategy 2 | Equipment 200 | Overhaul every 2 years |

| Inspect every 1 month | ||

| Asset Strategy 3 | Equipment 300 | Overhaul every 3 years |

| Inspect every 1 month |

- Equipment 100

- Equipment 200

- Equipment 300

In other words, one Object list Item record is created for each unique underlying Equipment record.

Create a Work Management Item (WMI)

Procedure

Copy and Paste a Work Management Item (WMI)

Procedure

Link Actions to a Work Management Item (WMI)

Procedure

Unlink an Action from a Work Management Item (WMI)

Procedure

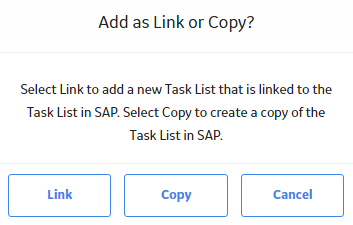

Link an Existing Task List in SAP to a Maintenance Item

Procedure

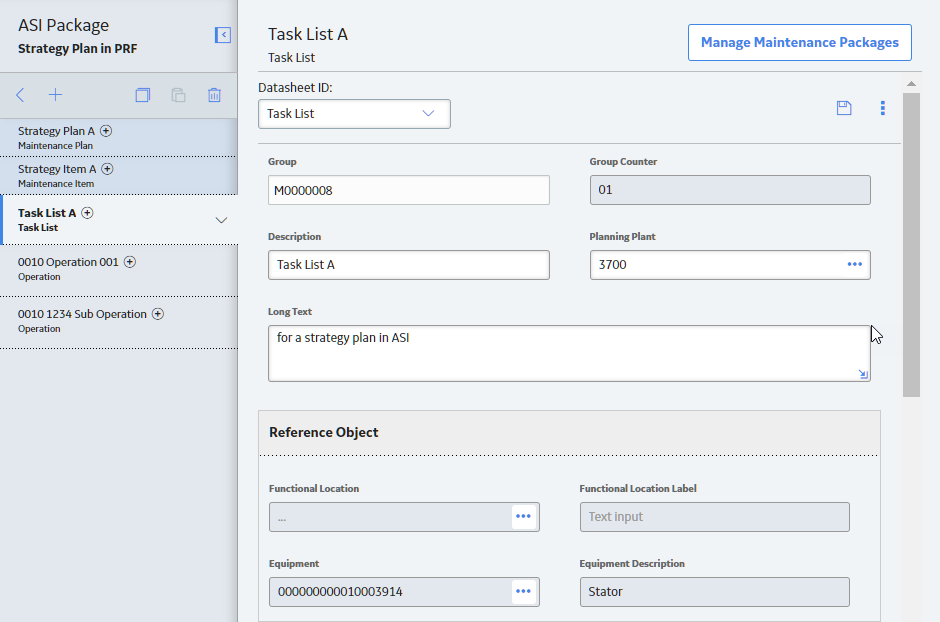

Manage a Maintenance Package from a Task List

About This Task

Procedure

Delete a Work Management Item (WMI)

Procedure

Results

- The following objects in SAP will be deleted:

- Operations

- Maintenance package

- Object lists under maintenance items

- The following objects in SAP will not be deleted:

- Maintenance plan

- Maintenance item

- Task lists

Synchronize Equipment or Functional Location Field in a Task List

Procedure

Results

- If the maintenance item contains a value in the Functional Location or Equipment field, the value is copied to the Functional Location or Equipment field in the task list.

- The field in the Task List record, to which the value was copied, is disabled, ensuring that the two values will never be different.

Maintain Object Lists

The Maintain Object List feature insures that Object List Item records are always in sync with the actions that are currently part of the Implementation Package.

, and then select the WMI type that you want to add under the parent you selected.

, and then select the WMI type that you want to add under the parent you selected. .

. icon appears next to the WMI to signify that it was added since the package was last implemented.

icon appears next to the WMI to signify that it was added since the package was last implemented. .

. .

.

.

.

.

. button appears instead of the

button appears instead of the  icon appears next to the WMI to signify that it has been deleted. When the package is implemented again, the WMI will be deleted, and the corresponding item in the SAP system will be deleted.

icon appears next to the WMI to signify that it has been deleted. When the package is implemented again, the WMI will be deleted, and the corresponding item in the SAP system will be deleted.