Planning ahead

Generator Health Monitoring for GE or other OEM generators

Digital monitoring for all generator types

GHM is a fully integrated and modular online, remote generator monitoring suite of modules available for any type of generator, that allows periodic or permanent assessment as well as the earliest identification of any evolving issues.

GHM supports the implementation of a cost-effective, condition-based generator maintenance strategy that increases a power plant's reliability and availability. It also allows improved outage planning and lifetime extension of the plant’s generators while optimizing maintenance planning.

Service levels

Find your GHM services level

Level 1 Sensors

Permanently installed generator monitoring sensors, including cabling and connection boxes.

Level 2 GOLD® Service

GE’s periodical online generator monitoring service allows you to cost-effectively assess the condition of a power plant's generator.

It involves the installation of permanent generator monitoring sensors, followed by biannual measurements and an expert report, allowing you to make informed decisions about your planned maintenance.

Level 3 Service

With our continuous generator online monitoring suite, operators will benefit from on-site trending as well as comprehensive half-yearly reports including recommendations to mitigate any risk of failure and to improve outage planning.

Level 4 Remote Services

For the highest level of assurance, we offer our remote generator monitoring system.

This remote generator monitoring system includes a permanent remote data link to the GE Remote Monitoring Center, allowing weekly checks as well as quarterly full reports, ensuring the earliest identification of any evolving issue.

Available Modules

Generator monitoring modules

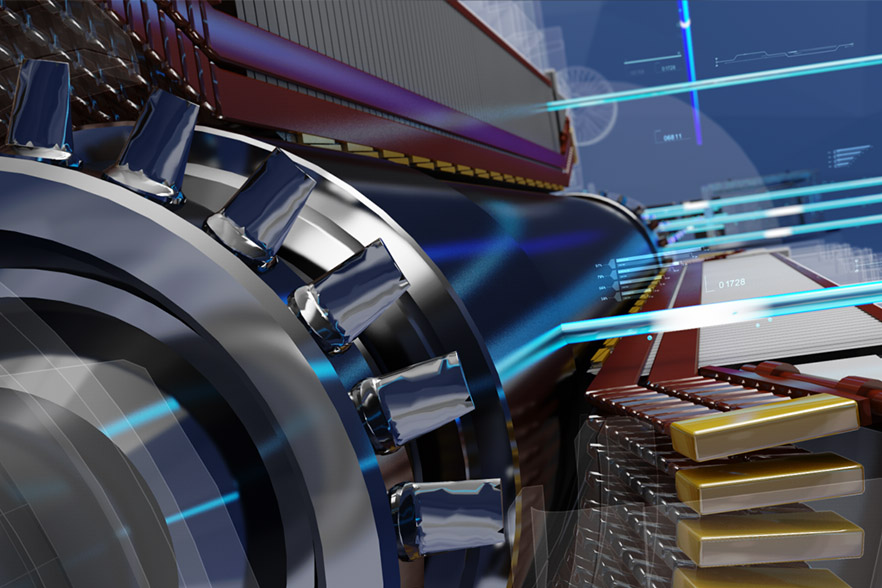

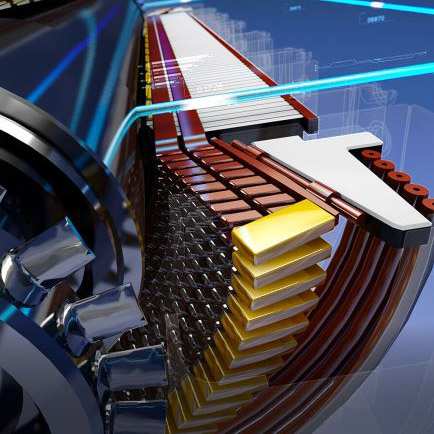

The fully integrated generator monitoring system is a modular system with a user-friendly web-based interface. With one care box, instead of several standalone systems, any combination or all of the following power plant generator parameters can be monitored in real time to assess conditions and the need for maintenance:

Partial discharge module

Monitors the partial discharges continuously within the stator winding and bus duct.

Rotor flux module

Tracks rotor winding inter-turn short circuits and identifies the magnitude and slot location of the fault.

Rotor shaft voltage module

Detects failures in the rotor winding insulation, shaft grounding system and excitation issues.

End winding vibration module

Provides continuous monitoring of stator end winding vibration location and magnitude.

Temperature generator sensor module

Generator sensor constantly monitors the generator temperatures in line with operating conditions, trending deviations from design values.

The generator monitoring system is also designed to be operationally compatible with most sensors produced and installed by third-party manufacturers.

Stator Leakage Monitoring System

Detection of hydrogen leakage into stator cooling water system (for generators with a high oxygen regime).

Collector Health Monitoring

Detection of sparking at exciter collector and brush assemblies to provide early warning to avoid a collector flashover.