Key benefits

Efficiency adapted to your plant

High efficiency

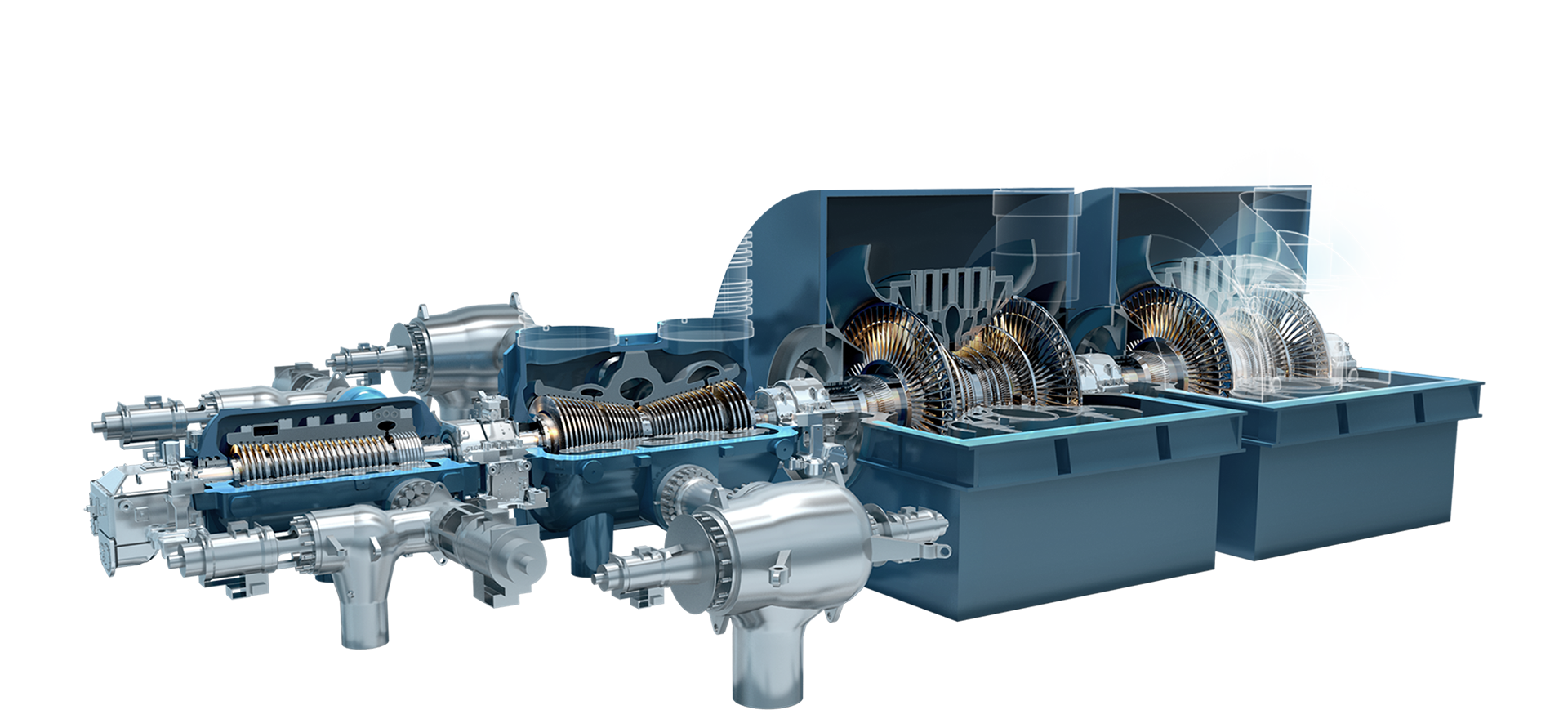

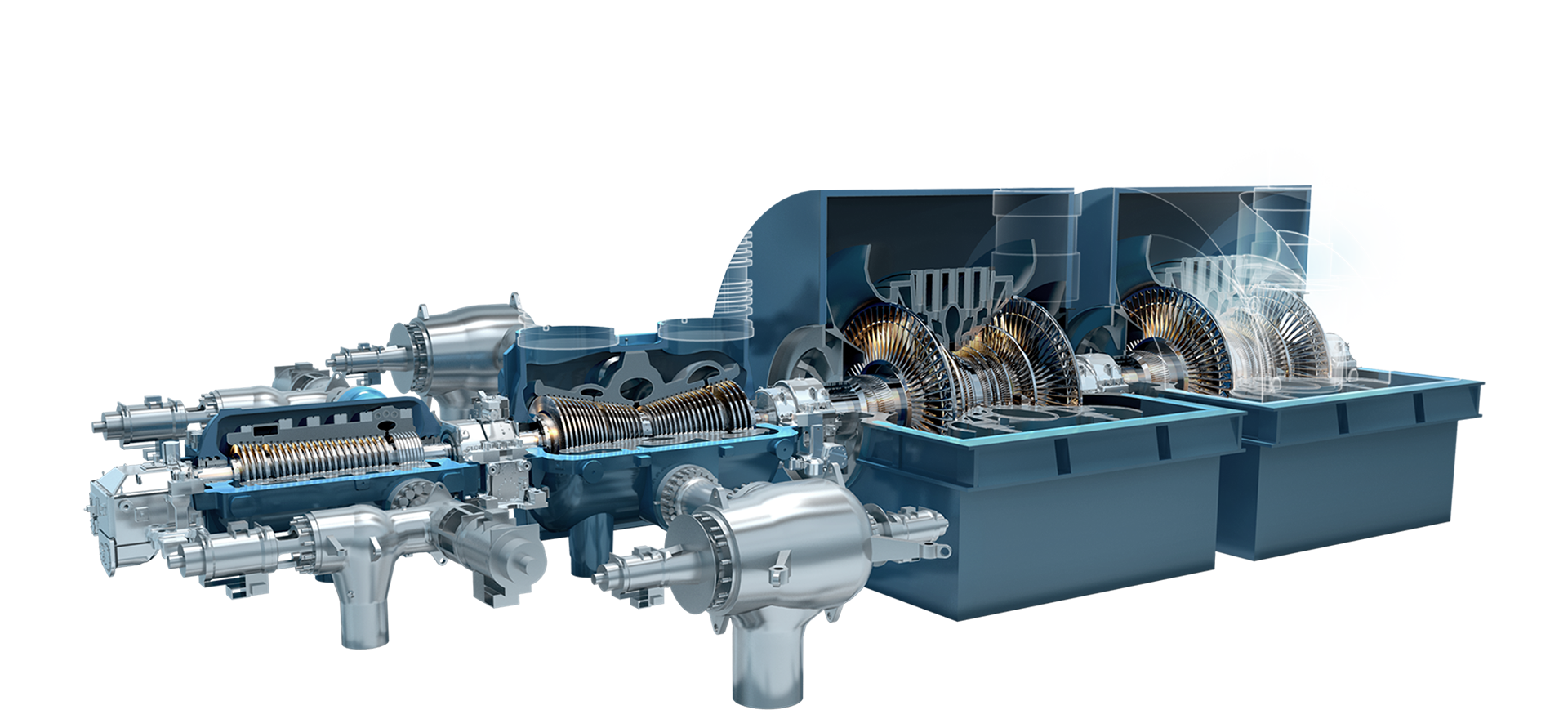

The STF-A850 and STF-D850 reheat steam turbines offer outstanding competitive performance for supercritical mid-size boiler steam plants, using GE’s latest generation of 3D reaction blading, advanced rear stages, and high-performance gland and inter-stage sealing technology

Detailed for integration

STF-A850 and STF-D850 reheat steam turbine modules are largely factory assembled and pre-tested to save installation time. An optional side exhaust configuration is optimized for low level arrangement and outdoor installation, which helps reduce the total installed cost.

Configuration flexibility

The fully modular architecture allows configuring the turbines for even the most demanding applications. Options include multiple controlled extractions, overload valves, and a wide range of LP configurations. Modules from other product families may be used as required.

Key features

STF-A850 and STF-D850 reheat steam turbine platform

A versatile platform optimized for mid-size supercritical boiler plant applications in either 50 or 60 Hz grids.

- Robust and versatile turbines with a successful track record spanning more than 30 years.

- Outstanding configuration flexibility including internally or externally controlled steam extractions and downwards or sideways lateral, exhausts.

- Time-saving installation thanks to fully assembled HP and IP modules and modular LP

- A design for more than 10,000 starts and optional stress controller and start-up valve (TAL) valve for rapid starts and transients make the STF-A850 and STF-D850 a great choice for cycling boiler plants and CCPP applications with a daily start/stop regime

- Overload capacity at constant boiler pressure and reliable trip-free emergency de-loading thanks to optional overload valves

- Increased turbine efficiency, cycling capacity, and back pressure capability with GE’s unique shrink ring HP module design and GE’s latest nub and sleeve/free tip rear stages with low stress root design

Specifications

STF-A850 & STF-D850 product specifications

Specifications shown are for 50 Hz and 60 Hz.

| STF-A850 | STF-D850 | |

|---|---|---|

| Main Steam | 245 bar (3,550 psig) | 245 bar (3,550 psig) |

| Main Steam / Reheat Steam Temperature | 585 °C / 585 °C (1,085 °F / 1,085 °F) | 585 °C / 585 °C (1,085 °F / 1,085 °F) |

| Output | 150 - 300 MW | 200 - 1,000 MW |

| Efficiency | ≤ 48% | ≤ 49% |

| Maximum Backpressure | ≤ 700 mbar (20.7 in. Hg) | ≤ 700 mbar (20.7 in. Hg) |

| Control Concept | Sliding pressure mode, Hybrid mode with or without overload valve | Sliding pressure mode, Hybrid mode with or without overload valve |

Further reading

Learn More

Related steam turbines

Related generators

Related links

- Steam Power Product Catalog