Key benefits

Efficiency and flexibility adapted to your plant

Low installed cost, quick start-up

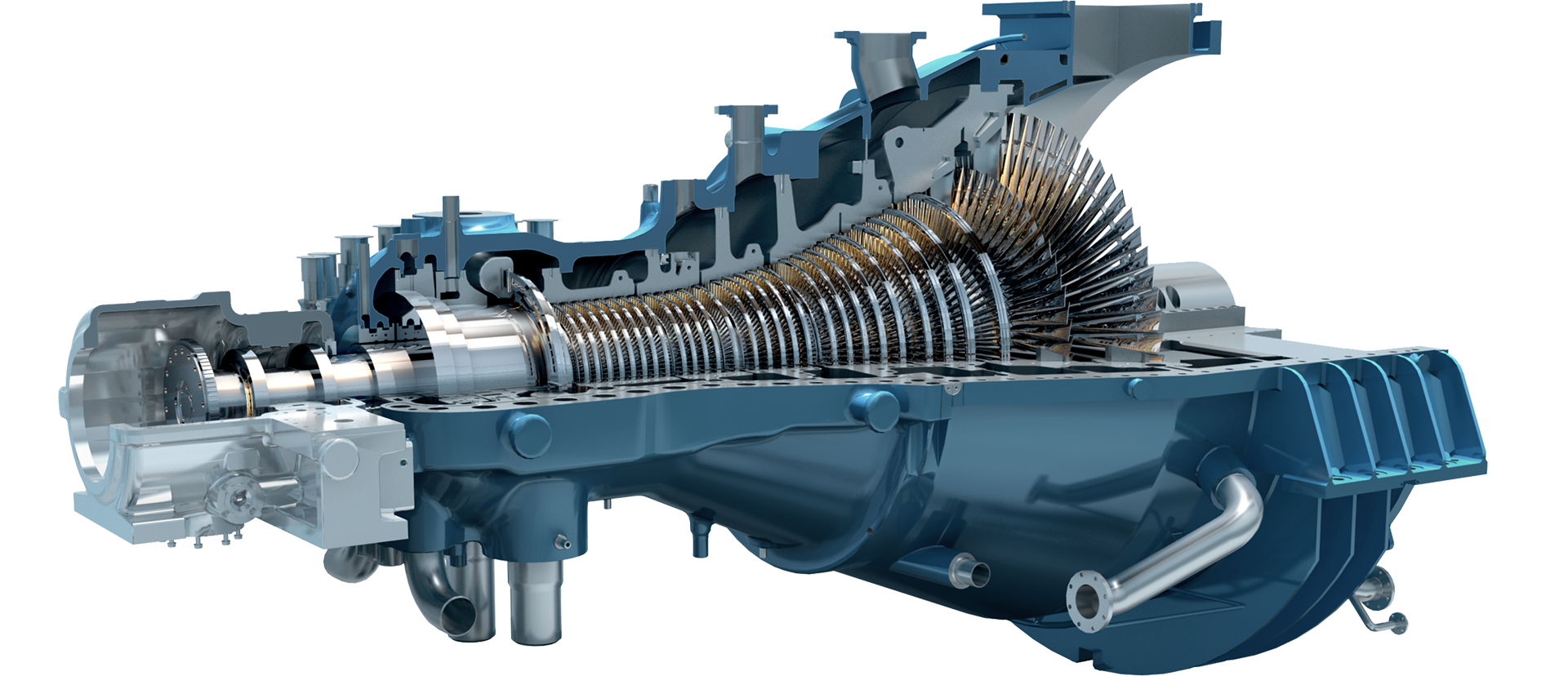

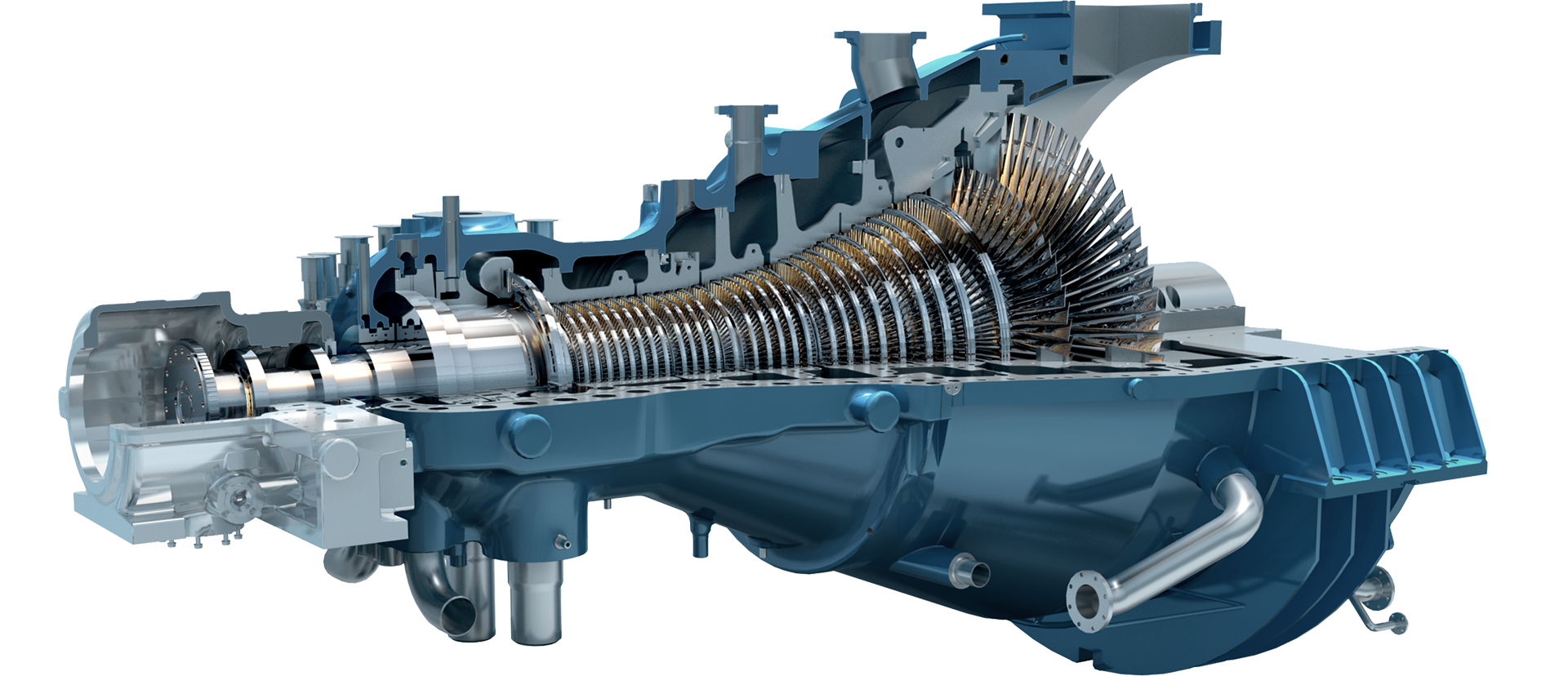

Designed for floor level installation or on a simple block foundation, the STF-A100 steam turbine lowers building construction time and cost. Installation time and cost is further reduced by shipping the complete steam turbine generator set in four pre-assembled and pre-tested modules.

Standard frames with customized steam paths

An intelligently designed range of highly standardized modules with a fully customized steam path allows configuration of the STF-A100 steam turbine for any application from a high-performance combined cycle power plant or biomass unit, to an industrial workhorse with process steam extractions.

High speed up to 135 MW

Building on GE’s unique experience with geared gas turbines of up to 135MW output, the STF-A100 non-reheat steam turbine offers the cost benefit of high-speed steam turbines for applications previously reserved to heavy synchronous designs.

Key features

STF-A100 non-reheat steam turbine product family

A versatile platform suitable for biomass, waste-to-energy or other renewable steam power applications as well as for combined cycle steam tails or complex industrial co-generation application in either 50 or 60 Hz grids.

- Reduced lead time thanks to more than 70% of standardized, fixed geometry components, which also helps improving quality, reliability, and maintainability

- Best performance for both boiler and CCPP applications through dedicated inlet configurations for turbine nozzle control (GRT) or sliding pressure operation (HRT)

- Competitive performance realized by utilization of advanced 3D controlled diffusion HP/IP blading from GE’s large industrial steam turbine portfolio

- High back pressure capability, exhaust wetness tolerance, and cycling capacity with GE’s latest nub and sleeve/free tip rear stage design

- Significant savings of integration cost and construction time resulting from delivery of the STF-A100 steam turbine in four fully assembled and pre-tested modules optimized for floor level installation

Product specifications

STF-A100 non-reheat steam turbine specifications

Specifications shown are for 50 Hz and 60 Hz.

| STF-A100 (HRT) | STF-A100 (GRT) | |

|---|---|---|

| Main Steam | 140 bar (2,030 psig) 565 °C (1,050 °F) | 125 bar (1,810 psig) 565 °C (1,050 °F) |

| Output | ≤ 135 MW | ≤ 135 MW |

| Efficiency | ≤ 42% | ≤ 42% |

| Maximum Backpressure | ≤ 500 mbar (14.8 in. Hg) | ≤ 500 mbar (14.8 in. Hg) |

| Control Concept | Sliding pressure mode, Fixed pressure mode, Hybrid mode | Sliding pressure mode, Fixed pressure mode, Hybrid mode |