October 3, 2019

THE TRUTH IS RIGHT HERE

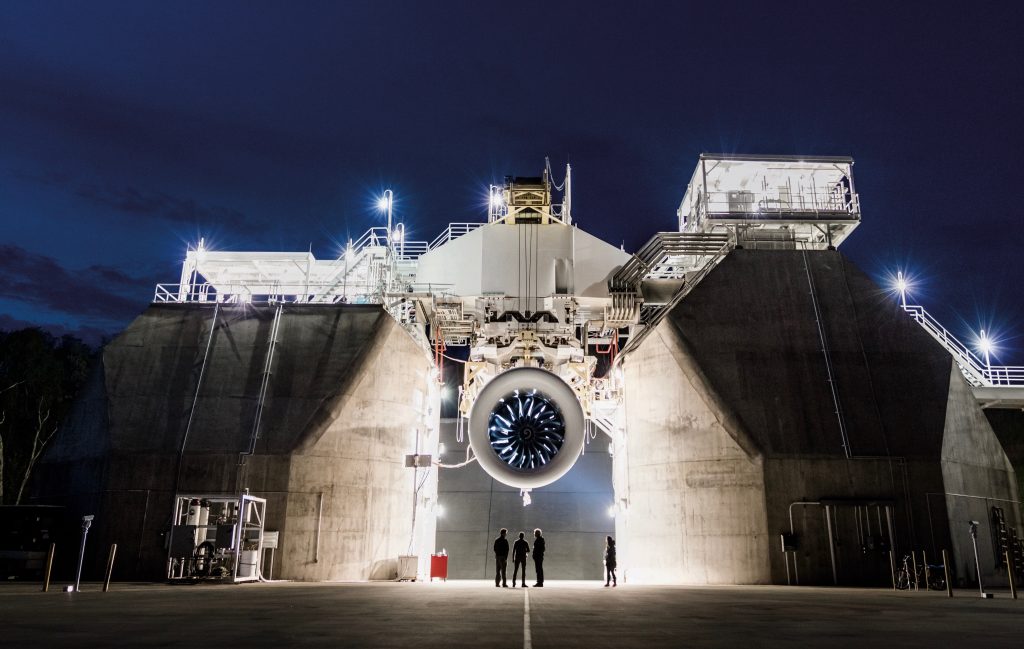

In the 1990s, a national cable-TV program came to GE Aviation, headquartered in Evendale, Ohio, with a striking request: It wanted confirmation that UFOs had made a nighttime landing at GE’s Peebles test site, two hours east in the Appalachian foothills. And why not? The ‘90s were a big time for UFO seekers — it was the decade of “The X-Files,” after all — and Peebles had long been cloaked in lore. Just what was going on there? Hate to disappoint but not little green men, exactly. It’s not flying saucers that engineers work on at Peebles, but jet engines. In fact, GE Aviation’s Peebles Test Operation, which puts production engines through their paces before they’re delivered to customers, has been the backbone of the largest commercial jet engine run in aviation history.

These engines are out of this world: Granted, the campus is big enough to accommodate a UFO or two. Surrounded by thick woods, the 7,000-acre complex — more than eight times the size of New York’s Central Park — is home to two massive indoor test facilities where more than 300 employees work around the clock to make sure new military and commercial development engines keep working when they fly through a hailstorm or hit a dust cloud. Workers also perform final assembly on engines for the record-breaking GE90 and GEnx commercial engines, among others. What goes on at Peebles isn’t a matter of dark conspiracy, but there is some historical reason behind the legend: The site began life at the height of the Cold War as an outdoor test facility for top-secret military engines.

What a long, strange trip it’s been. Click here for more on the evolution of GE Aviation’s ultra-important, not-so-enigmatic Ohio proving grounds.

SPECIAL DELIVERY

The skies might not be filled with unidentified flying objects but they’re increasingly populated with unmanned aerial vehicles, or UAVs. That’s a trend that’s sure to increase as commercial uses for drones take off — and as they gain regulatory approval. The Federal Aviation Administration gave the industry a boost this week when, for the first time, it bestowed broad certification to UPS Flight Forward, a subsidiary of UPS, to operate a “drone airline.” CNBC called the approval “a milestone in commercial drone delivery,” noting that several companies, including Amazon and Uber, are racing to get their unmanned fleets into the skies. The first item on UPS Flight Forward’s agenda? Expanding drone deliveries to hospitals nationwide.

Get in the drone zone: Drones today are often just expensive toys — but if they’re approved for commercial use, the sky’s the limit in terms of what UAVs can do. Drones could inspect remote pipelines for damage, for instance, or deliver human organs for transplant — as one unmanned vehicle did earlier this year in a pioneering flight over Baltimore. It did so with the help of GE Aviation’s AiRXOS, which makes a cloud-based infrastructure and application platform for unmanned vehicle operations. For the past couple years, AiRXOS and industry partners have teamed up with the FAA for tests to figure out how best to manage the increased air traffic that will come with commercial drone operations. Last month they completed real-world test flights in the first phase of designing the air traffic management system of the future.

Click here to learn about AiRXOS and GE Aviation’s role in drone testing, and here for details on the new FAA approval.

STEAM PLAYER

The steam turbine was a revolutionary invention in 1884, and more than a century later engineers continue to rely on steam to operate the turbines that supply a lot of the world’s electrical energy. Still, the technology might be due for a 21st-century update. That’s the focus of work being done at GE Research in Niskayuna, New York, where Peter deBock and his colleagues are designing ways to optimize the performance of steam turbines, raising their operating temperature and increasing thermal efficiency — in short, allowing turbine operators to get more bang for their buck. To achieve this, deBock and colleagues are trading steam for CO2 (the stuff that gives fizziness to soda and Champagne) and using new materials and 3D printing. To get the most out of these materials, they take inspiration from the result of hundreds of million years of evolution: human lungs.

A lung way to go: DeBock and his GE Research team are focusing on the heat exchanger, an essential component of the cooling system. It is used to capture energy flowing from the primary gas turbine and transfer it to a secondary steam turbine power loop to generate yet more electricity. Lungs are “the ultimate heat exchanger” — they play an important role in cooling the body. That’s also where deBock and his colleagues looked for inspiration, designing an intricate heat exchanger modeled after the lungs’ system of capillaries. The part, made from an advanced nickel superalloy for use in jet engine parts, can move CO2 at higher temperatures and pressures thanks to this ingenious bio-inspired design. “With 3D printing,” deBock said, “we can build design architectures that were previously impossible.”

Learn more here about how 3D printing is making the impossible possible — and how the U.S. Department of Energy is paying attention.

— VIDEO OF THE WEEK —

— QUOTE OF THE DAY —

“With 3D printing, we can build design architectures that were previously impossible.”

— Peter deBock, principal engineer and specialist in Thermal Management at GE Research

Quote: GE Reports. Image: Chris New for GE Reports.

ENJOY THIS NEWSLETTER?

Please send it to your friends and let them know they can subscribe here.