In 1998, a gas turbine, like the GT26, led a predictable life: operate at baseload and get serviced at regular maintenance intervals.

Fast forward 20 years, and that baseload machine now must contend with a transformational shift in the power industry. The rise of renewables, the retirements of coal and nuclear plants, advances in gas turbine technology, increased competition across fuel sources, and emissions legislation are changing market dynamics across the globe – including Europe, Middle East, and Asia, where most of the GT26 fleet is located.

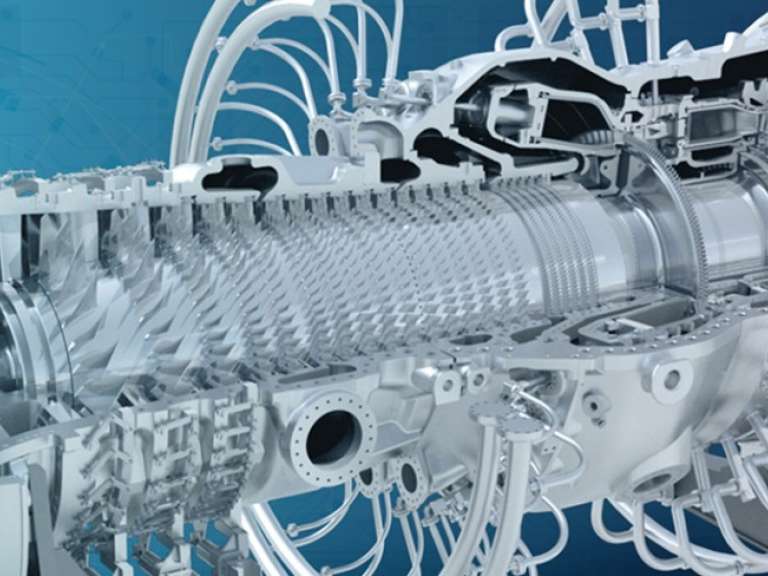

A new high efficiency upgrade, which combines F- and H-Class gas turbine technologies, is giving GT26 operators a solution to remain competitive by providing both base-load and part-load efficiency improvements never before seen on this fleet. This new technology will enable higher output capabilities for peak power periods, and longer maintenance interval, which is especially relevant when operating a daily shifting profile.

Renewables Meet High-Efficiency Turbines

There is no denying renewables are becoming a growing proportion of the power generation mix. "But, with retirements in coal and nuclear power generation, you still have to rely on gas plants for continuous, stable power generation,” said Amit Kulkarni, platform leader for GE’s F- and H- Class gas turbine services.

In this symbiotic relationship between renewables and natural gas, traditionally base-load gas turbines are being required to ramp up and down quickly. These market dynamics have led to new investments in gas turbine and combined cycle plant efficiency, flexibility, and reliability. "When I think of the progression in the gas turbine world, it has been the leap from lower firing temperatures and efficiencies to a class that has the highest efficiencies in the industry," says Kulkarni.

This has certainly been true for the GT26. Over its two-decade history, the service offerings for the fleet have evolved from focusing on delivering additional output, to an emphasis on efficiency and flexibility. GE’s introduction of its new High Efficiency (HE) upgrade for the GT26 “represents the most significant innovation on this platform ever done,” according to Kulkarni.

Combining F- and H-Class Technology

This upgrade crosses several new frontiers. It’s the first-ever upgrade to combine significant technology from both F- and H-Class fleets. It’s also the first-ever solution that blends GE technology with Alstom’s GT26 units. In addition, it integrates additive manufacturing to enable unprecedented efficiency gains.

The GT26 HE is expected to deliver exceptional levels of combined cycle efficiency, improving combined cycle baseload efficiency by 2+%*, resulting in annual fuel savings of up to $4 million. In part-load, fuel savings can yield up to $1 million in a year. Improved efficiencies mean that plant output can rise 15-55 MW per unit, while maintenance inspections can be extended up to 32,000 operating hours.

“What the HE does is deliver exceptional levels of baseload and part-load performance to ensure that these units are extremely competitive and complement the renewables being introduced in many markets,” Kulkarni states. “In traditional base power markets, the GT26 HE will deliver huge fuel savings. In renewable balance markets, it will help these plants compete and be utilized more,” says Kulkarni.

External forecasts support a global gas turbine market of 35-40 GW per year driven by better access to gas and 400 GW retirements globally over the next 5 years. We’ll see the generation mix continue to shift toward substantially more renewables, but natural gas generation is the best complement to support it with dispatchable, flexible, affordable, and fast power. GE’s GT26 HE upgrade is leading the way in new flexible, high efficiency solutions that are at the cutting edge of the power industry, helping drive competitive performance for today and tomorrow.

*for rating GT26 2006 configuration