What Should Flexibility Mean to Your Plant?

David AppleyardEnergy flexibility is as varied as it is valuable. Here's a look at how to identify and capitalize on the form of flexibility that's right for your plant.

Flexibility in the energy sector comes in multiple guises, but everyone agrees on one thing: It's important. The ability to offer peak shaving, frequency- and voltage-stabilization services, and a host of other new functions represents an opportunity to capitalize on the rapidly changing energy landscape.

Deciding what type of flexibility is right for your plant or fleet is heavily dependent on customer demands. Here's a look at a few different energy flexibility strategies and the contexts in which they're valuable.

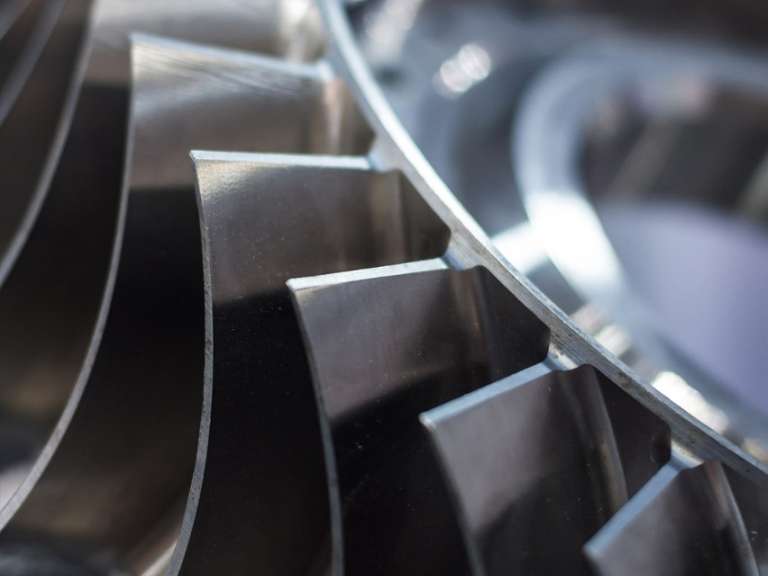

Asset owners and operators hoping to improve their energy flexibility might consider smaller aeroderivative or simple-cycle gas turbines as the obvious choice. But all is not lost for large, combined-cycle installations when it comes to solving the flexibility equation.

Delivering more flexibility for plants designed to run at baseload can mean choosing between a multitude of possible performance modes, each potentially representing a different technical solution. For asset managers, the key to determining a route to energy flexibility is to assess the financial benefits that different operational modes can bring. This process requires an open dialogue with other organizational elements. Exchanging ideas with the energy-trading team, for example, can help you determine the most desirable operational characteristics to pursue.

Determining the best flexibility options according to a cost-benefit analysis puts you in a good position to assess the value of any potential investments. The central goal is profitability, which is inevitably shaped by market structures and requirements. The bottom line is that managers of combined-cycle units can pursue flexibility profitably according to several models.

In some regions, the power system is rapidly changing due to increasing renewables penetration. A high-efficiency turndown, or "parking mode," and the ability to ramp rapidly could yield significant advantages here.

In 2015, for example, changing grid demands prompted A2A, the Italian utility company, to modernize the four combined-cycle units at its Chivasso plant in Lombardia. For A2A to compete successfully in the ancillary-services market, very low load levels were critical. With the help of a software solution, it reached a 65-MW minimum load per turbine from a 300-MW machine, and more than doubled ramp rates.

The ability to provide additional peak power above the rated capacity represents an attractive business proposition when prices spike. Increasing peak output enables operators to take advantage of high spot-market prices during peak hours.

UK-based Uniper Energy plans to pursue this path with its combined-cycle assets located in Enfield and Grain by adopting a solution to boost their performance in the peaking market. Uniper plans to boost the capacity at the 400-MW and 1,200-MW stations by up to 4 percent. This will enable it to capitalize on the high-demand regions of greater London and the southeast of England.

In some regions, supply-and-demand characteristics may favor the ability for a quick start-up after a weekend shutdown.

Southern California Edison's 1,054-MW Mountainview plant in Redlands, California, needed more flexibility to respond faster to California's ISO system demands. An upgrade package reduced start-up times and lowered emissions without using additional water. Maximum output also increased by about 48 MW.

In other markets, fuel flexibility is central to security of supply and a must-run strategy. Fuel flexibility may be required, for example, at a petrochemical refinery site where a combined-cycle unit could run partly on refinery-process gas. This reduces flaring and saves expenditure on fuel. Additional exhaust-gas treatment may be required to achieve the advantages of fuel flexibility while meeting environmental standards.

Plant and asset managers are typically tasked with keeping a very tight grip on O&M expenditure. New operational modes requiring partial load, idling, or multiple start-stop cycles over a 24-hour period can potentially play havoc with that budget.

However, plant managers can face up to this challenge without necessarily compromising their core objectives. With the right upgrades to match performance requirements, they can maintain or even improve plant O&M characteristics.

For asset owners and operators, any investment needs to represent a solid business case, often with a payback time of three years or less. For large, combined-cycle power plants, a move to more flexible footing is often mandatory for continued operations. That is a compelling story to tell stakeholders.

Demand-side response technology can help utilities better manage load dispatch at times of peak demand, gain greater insight into customer behavior, and capture new revenue streams.

In a fast-changing landscape, organizations must stay aware of potential cyber threats. Data protection and security are priorities.

Virtual reality may be more closely associated with gaming than big business, but for the power sector VR can yield substantial benefits. It's when 3D becomes 4D that things get really interesting.