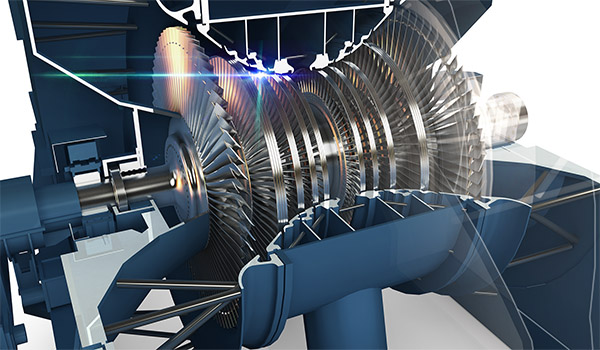

Steam turbines for fossil, nuclear, and renewable applications

A comprehensive steam turbine portfolio of solutions to fit your power plant needs

Or start with a popular search:

A comprehensive steam turbine portfolio of solutions to fit your power plant needs

YES. For more than a century, we have engineered and manufactured the latest technologies to provide highly efficient and reliable steam turbines for fossil, nuclear, and renewable applications. GE has supplied more than 30% of the world’s installed steam turbine capacity and 50% of the nuclear steam turbines, which are collectively generating more than 1,200 GW of power.

GE’s steam turbine platform offers a broad product portfolio of solutions that accommodate a wide range of site conditions, operational needs, advanced steam cycles, and applications. Our steam turbines share common features and components that enhance the reliability, efficiency, and availability of your plant.

Introduced in 1930, our welded rotor technology has stood the test of time, with no ruptures reported in our large diameter steam turbine rotors-manufactured by welding together separate smaller forgings. This allows for:

Innovative blading technology is apparent in our:

Our enhanced last stage blade portfolio for steam turbines offers:

Our multi-casing steam turbines have a single bearing between each turbine section for:

GE’s Arabelle turbine is the most powerful nuclear steam turbine in operation. Suiting all reactors type, from 700MW up to 1,900MW, the Arabelle is highly efficient, reliable, and cost effective.

Configuration:

GE’s Arabelle turbine is the most powerful nuclear steam turbine in operation. Suiting all reactors type, from 700MW up to 1,900MW, the Arabelle is highly efficient, reliable, and cost effective.

Configuration:

The STF N700 turbine offers robust architecture and cutting-edge blading technology adapted to any backpressure conditions.

Configuration:

The STF-D650 reheat steam turbines have proven their value in concentrated solar power, combined cycle and industrial applications.

Configuration:

The STF-A650 (MT) steam turbine has proven their value in concentrated solar power, combined cycle and industrial applications.

Configuration:

The STF-D250 (MT) non-reheat steam turbines provide superior value in renewable and industrial applications

Configuration:

The STF-A200 non-reheat steam turbine provides superior value in renewable and industrial applications, by combining a modern steam path with the flexibility of a fully modular turbine architecture

Configuration:

The high speed STF-A100 (GRT/HRT) non-reheat steam turbine family provides up to 135MW of low cost and flexible power for renewable steam plants like biomass, concentrated solar power, waste to energy, and industrial applications.

Configuration:

The STF-G220 (GST) geothermal steam turbine offers a simple and robust technology for geothermal projects and industrial low-pressure expander applications.

Configuration:

Designed for advanced ultra-supercritical (A USC) steam cycles, the STF-D2250 steam turbine pushes your plant efficiency to new levels

Configuration:

Designed for advanced ultra-supercritical (A USC) steam cycles, the STF-D1250 steam turbine pushes your plant efficiency to new levels

Configuration:

The STF-D1050 steam turbine family expands the range of ultra-supercritical (USC) steam turbines all the way from 150MW to over 1200MW

Configuration:

The STF-A1050 steam turbine family expands the range of ultra-supercritical (USC) steam turbines all the way from 150MW to over 1200MW.

Configuration:

The STF-D850 supercritical reheat steam turbine family addresses the needs for flexible and highly performant supercritical steam for mid-size plant applications

Configuration:

The STF-A850 supercritical reheat steam turbine family addresses the needs for flexible and highly performant supercritical steam for mid-size plant applications

Configuration:

The STF-D650 reheat steam turbines have proven their value in concentrated solar power, combined cycle and industrial applications.

Configuration:

The STF-A650 (MT) steam turbine has proven their value in concentrated solar power, combined cycle and industrial applications.

Configuration:

The STF-D250 (MT) non-reheat steam turbines provide superior value in renewable and industrial applications

Configuration:

The STF-A200 non-reheat steam turbine provides superior value in renewable and industrial applications, by combining a modern steam path with the flexibility of a fully modular turbine architecture

Configuration:

The high speed STF-A100 (GRT/HRT) non-reheat steam turbine family provides up to 135MW of low cost and flexible power for renewable steam plants like biomass, concentrated solar power, waste to energy, and industrial applications.

Configuration:

Steam Power offers a broad portfolio of technologies and services predominantly for nuclear and coal power plants helping customers deliver reliable power as they transition to a lower carbon future.

Contact usPower operators are facing growing pressure to drive plant performance to new levels. They need a trusted partner with the expertise, technology and resources to achieve their desired outcomes.

Explore our expertise