Benefits

Choices for performance, reliability, and lifetime extension

Our more than 45 years of manufacturing experience, an installed base of over 20 countries, and our legacy Alstom heritage provides GE with the industry knowledge that puts your balance of plant equipment in good hands.

Proven features

- Demonstrated enhancement of heat exchanger performance and lifetime (both in nuclear islands and turbine halls)

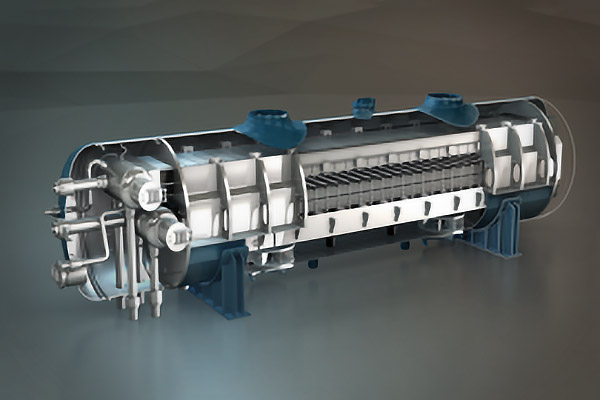

- Proven OEM experience with moisture separator reheaters (MSR), high- and low-pressure heaters, condensers, and condenser-tube cleaning systems (CTCS)

- Continuous innovation in engineering and onsite activities to decrease outage cost and duration

The benefits of service

Get more information about our heat exchanger improvement services.

Tube bundle replacement procedure

From replacement with identical tubes to resizing for a power upgrade, GE can tailor the solution to meet your specific requirements.

Benefits of heat exchanger tube bundle replacement:

- Improved MSR performance

- Possible uprate in power

- Ability to adapt to new operating parameters and environmental conditions

- Up to 20 years of extended equipment lifetime

- Enhanced ability to meet regulatory requirements (including local pressure equipment regulations)

Learn more about our balance of plant inspection and assessment services.

Inspection services—MSR performance maintenance

In addition to statutory controls, GE provides a comprehensive view of the state of the MSR through our experience as a manufacturer. Our team can identify potential issues and propose preventive maintenance as well as review operations and reliability.

Benefits of inspection services:

- Take advantage of GE’s OEM expertise and fleet experience

- Thorough evaluation of MSR operation: mechanical, thermal aspects

- Identify critical work to be undertaken with prioritization and estimated costs

Discover how to maintain your condenser performance thanks to continuous cleaning solutions.

Condenser tube cleaning system (CTCS)

We design and provide the CTCS your equipment needs. Our automatic condenser tube cleaning methods, formerly known as Technos solutions, help to maintain power plant efficiency. GE can adapt to your individual flow and water constraints, ultimately delivering the solution that works for your needs, from design to manufacturing.

Benefits of employing a condenser tube cleaning system:

- Maintain condenser performance

- Continuously clean an operating unit—with no shutdown

- Works without any chemical treatment

- No environmental impact

Pumping systems

Pumps and motors

We offer a wide range of experience on a number of different power plant pumping systems (both in nuclear islands and turbine halls). From regular maintenance operations to complete replacement, GE can provide the right solution that fits your needs, as your nuclear pump manufacturer.

GE experience in nuclear

OEM experience of nuclear power plant motors and pumps:

- Bergeron, Rateau, Acec

- Steam turbine-driven feedwater

- Residual heat removal system

- Condenser extraction system

- Safety injection system

- Containment spray system

- Auxiliary feedwater system

- Repairs can be made in GE workshops or on customer sites

- Full maintenance—including decontamination

- Manufacturer (shafts, windings, rotors, insulation, wiring)