Enhancing performance, lowering lifecycle costs

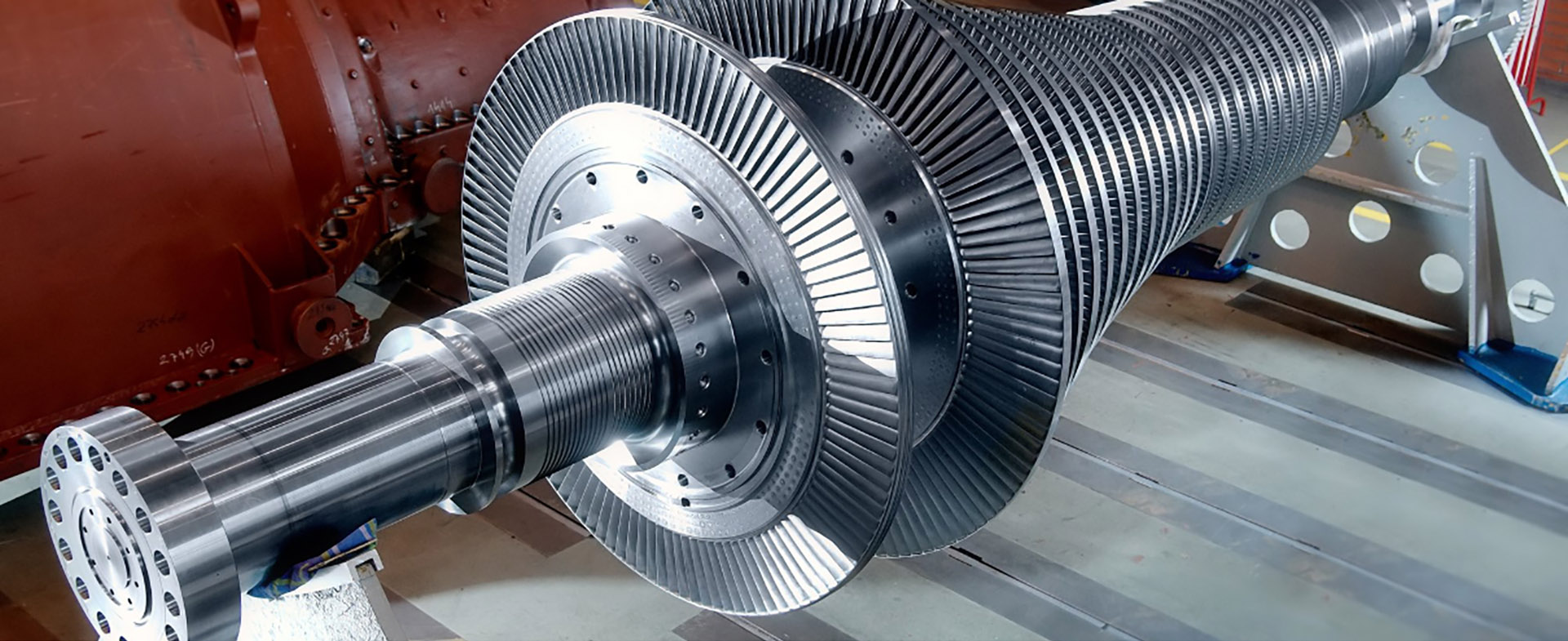

In today’s dynamic and competitive business arena, industrial plant operators and steam turbine repair companies are under more pressure than ever to enhance the performance and lower the lifecycle costs of their equipment. With more than 120 years of turbine experience, GE is a global leader in power generation technology and services.

GE’s industrial steam turbine service organization combines the expertise of an original equipment manufacturer with the flexibility of an independent industrial steam turbine service provider. With the presence of technically advanced solutions, service facilities, and first-class engineers, we can provide fast responses, faster outage times, and the highest technical standards—all while meeting strict EHS practices.