Keeping you competitive

A wide range of solutions

Should your operating strategy require end-of-life or life extension planning, we offer a range of cost-effective options. . To increase reliability and reduce downtime, we offer the following parts-related services:

- Inventory management

- Equipment rebuild programs

- Technical support

- Outage kits

- 24/7 emergency support and expedited components

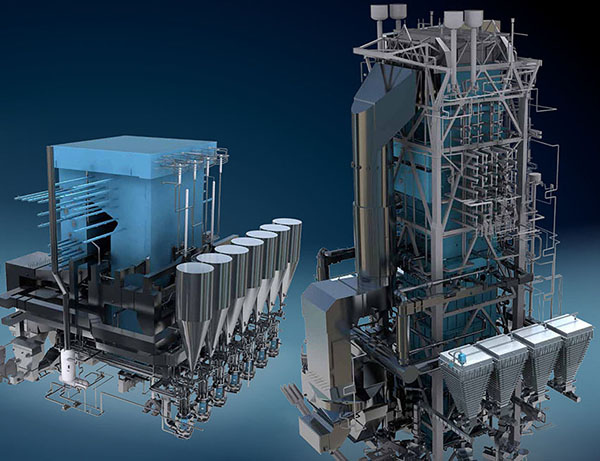

Boiler components

Delivering a full range of boiler parts and components

Pulverizers, mills, and auxiliary equipment

- Replacement parts for all mill types

- Advanced static and dynamic classifiers

- Grinding elements

- Vane wheels

- Gearboxes

- Feeders

Pressure parts

- Boiler tubing—straight or fabricated

- Superheater

- Reheater

- Economizers

- Headers

- Panels

- Desuperheaters

- Drum internals

- Sootblowers

- Attachments

- Smelt spouts

Fuel delivery and firing systems

- Oil guns

- Coal piping and elbows

- Riffle distributors

- Tips

- Nozzles

- Low NOx burner upgrades

- Windboxes

- Dampers

- Tangential- and wall-fired burners

- Stokers

- Black liquor nozzle

Electronics and controls

- LIMELIGHT* boiler electronic products

- Ignitors and HEI ignition

- Flame spectrometers and scanners

- Control cabinets

- Process instruments

- Burner management systems

- Non-retracting oil guns

Bottom ash and fly ash systems

- Products and services for UCC, A-S-H, and GE’s bottom ash and fly ash systems

- Clinker grinder rebuilds

- Hoppers

- Seal skirts

- Waterboxes with weir piping

- Front enclosures

- Ash gates

- E-valves

- Airlocks

- Dry drag conveyors

- Pugmills

- Submerged scraper conveyors

Balance of boiler

- Access doors

- Ductwork and expansion joints

- Refractory, insulation, and lagging

- Dampers