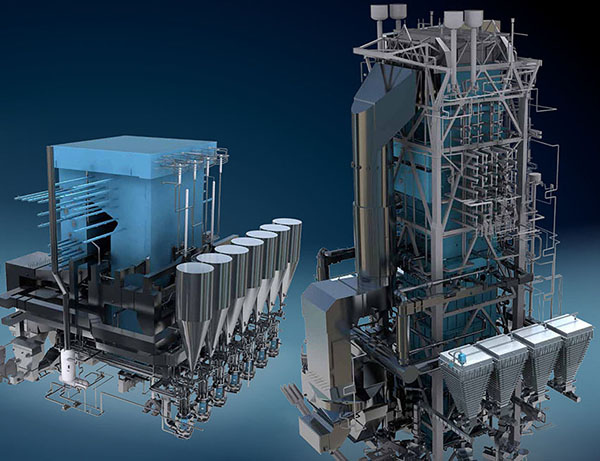

Can GE service my boiler mills?

YES. Our boiler mills and coal pulverizers span the globe and are built in a variety of sizes and capacities. We provide customized maintenance solutions, and offer a full spectrum of high-quality solutions for each—in addition to our thousands of standard boiler mill parts and boiler service solutions. This is the Power of Yes.

Servicing legacy boiler mills:

- CE (Combustion Engineering)

- ABB

- EVT

- Alstom

Our offerings include:

- Boiler mill replacement parts

- Digital mill-optimization applications

- Mill rebuild programs

- Boiler mill inventory management

- Major coal mill retrofits

- Unique boiler mill solutions

- Multi-year agreements

Key performance and flexibility

Global fleet and project experience

In an ever-changing regulatory environment, flexibility and expertise are critical. With global fleet and project experience, we can help to enhance boiler mill performance and reduce lifetime costs—but never at the expense of safety, reliability, or environmental compliance.